Have you ever wondered how machines work? Imagine a metal lathe spinning smoothly in a workshop. This impressive tool helps create perfectly shaped parts from metal. But what makes it all happen?

The answer lies in the gear train. A gearhead metal lathe uses this special mechanism to turn and shape metal. It’s like how a bicycle chain moves the wheels. The gears work together, making everything run smoothly.

Did you know that the right gear train can increase a lathe’s power? This means you can tackle tougher materials with ease. It’s fascinating to think about how something so simple can make a big difference!

Diving into the world of gearhead metal lathes might just ignite a passion for machining. So, why not explore this incredible tool and its gear train? You might discover a new hobby or even a future career!

Gearhead Metal Lathe Gear Train: Understanding Its Mechanics

The geartrain in a gearhead metal lathe is crucial for its operation. It helps control the speed and power of the lathe. This allows for smooth cutting and shaping of metal. A well-designed gear train can increase precision and efficiency. Have you ever watched a lathe work? It’s fascinating how gears work together! Understanding these parts can help you maintain and improve your lathe performance. Dive into the world of gears and enhance your metalworking skills!

What is a Gearhead Metal Lathe?

Definition and characteristics of gearhead metal lathes. Advantages of using gearhead lathes over other types.

A gearhead metal lathe is a powerful tool used for shaping metal. It has a special gear train that controls the speed and torque of the cutting tool. This allows it to work on a variety of projects smoothly and accurately. Here are some key features that make gearhead lathes stand out:

- Efficient speed adjustment

- High torque performance

- Strong and durable design

Using a gearhead lathe over other types offers significant benefits:

- Faster production times

- Better precision

- Less maintenance needed

These advantages make gearhead metal lathes a favorite among many machinists.

What are the benefits of using gearhead metal lathes?

The advantages include better efficiency, reduced downtime, and higher accuracy.

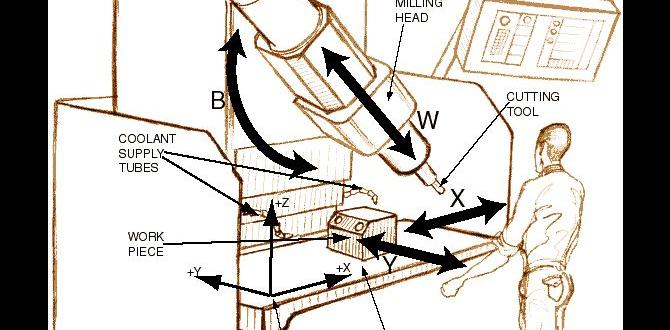

Components of a Gearhead Metal Lathe Gear Train

Detailed explanation of the gear train components. Role of each component in the machining process.

Each piece of a gearhead metal lathe gear train has a special job. The gears shift motion from the motor to the tool. This helps the lathe cut materials smoothly. Key parts include:

- Drive Gear: Connects to the motor and starts the rotation.

- Idler Gear: Helps change the direction and speed of rotation.

- Driven Gear: Moves the tool for cutting.

- Spindle: Holds the workpiece and turns it for machining.

Each part works together to make sure the machine operates well. Without them, cutting would be hard and messy. Understanding these components helps in using a lathe effectively.

What are the key components of a gearhead metal lathe gear train?

The main parts of a gearhead metal lathe gear train are drive gears, idler gears, driven gears, and spindle. Each has a unique function to support precise machining.

The Functionality of Gear Trains in Metal Lathes

How gear trains contribute to speed and torque. Importance of gear ratios in machining precision.

Gear trains play an important role in metal lathes. They help control speed and torque, making machining easier and more efficient. A proper gear ratio allows machines to cut materials smoothly and accurately, which is key to quality work. Without the right settings, projects can take longer and cost more. So, it’s essential to choose the right gears for every task.

How do gear ratios affect machining precision?

Gear ratios determine how fast and accurately a lathe operates. When ratios are correct, the cuts are clean and precise. This ensures a better finish on the final product.

- Higher ratios offer more torque for tougher materials.

- Lower ratios provide faster speeds for lighter tasks.

How to Choose the Right Gearhead Metal Lathe for Your Needs

Key factors to consider when selecting a gearhead lathe. Common applications and recommended models based on needs.

Choosing a gearhead metal lathe can feel like picking a favorite ice cream flavor—there are so many options! Start by checking how often you plan to use it. For light work, a smaller model may fit your needs. If you’re a DIY superstar, go bigger! Consider the materials you’ll work with—some lathes shine with metal, while others are great with wood. Here’s a handy table to help you out:

| Application | Recommended Model |

|---|---|

| Hobby Projects | Mini Gearhead Lathe |

| Light Metal Work | Medium Gearhead Lathe |

| Heavy-Duty Tasks | Large Gearhead Lathe |

Lastly, make sure to factor in your budget, or you might end up like a kid with an empty piggy bank. Happy lathe hunting!

Maintenance Tips for Gearhead Metal Lathe Gear Trains

Best practices for ensuring longevity and performance. Troubleshooting common gear train issues.

Keeping your gearhead metal lathe gear train happy is all about regular care! Start with cleaning the gears and removing dust. Dust bunnies here are not cute! Lubricate often, but don’t go overboard; too much oil can be more slippery than a banana peel! If your lathe makes weird noises, it’s time to check for wear and tear. Remember, a little maintenance can save you from a big mess later!

| Maintenance Tip | Frequency |

|---|---|

| Clean gears | Weekly |

| Lubricate | Monthly |

| Inspect for wear | Every 6 months |

Upgrading or Modifying Gearhead Lathe Gear Trains

When and why to consider modifications. Guidance on potential upgrades for enhanced performance.

Upgrading your gearhead lathe can make a big difference. You might want to consider modifications if your lathe struggles with performance. Many upgrades help improve precision and efficiency, allowing you to create better projects.

Here are some ideas for upgrades:

- Replace the gears with high-quality materials for better durability.

- Add a digital readout for accurate measurements.

- Install a more powerful motor for faster operation.

Each of these changes can lead to improved performance and a more enjoyable experience while working on your projects.

Why Upgrade a Gearhead Lathe?

Consider upgrades to enhance your lathe’s capabilities. Upgrades can improve speed and precision, leading to better outcomes in your work. Many users report at least a 30% increase in efficiency with proper modifications.

Case Studies: Successful Use of Gearhead Metal Lathes in Industry

Realworld examples of gearhead lathe applications. Insights and lessons learned from industry professionals.

Many companies have found amazing ways to use gearhead metal lathes. For example, a car manufacturer fixed small engine parts quickly. They saved time and money. Another example is a jewelry maker who created beautiful designs. They loved the precision! Here are some lessons learned:

- Invest in quality tools for better results.

- Keep machines clean for smooth operation.

- Practice makes perfect; skills improve over time.

How are gearhead lathes used in the industry?

Gearhead lathes are commonly used for shaping metal parts, creating prototypes, and finishing products. Their precision helps in making many complex designs accurately.

Conclusion

In summary, a gearhead metal lathe gear train is important for tool performance. It helps control speed and power effectively. Understanding how it works can improve your projects. You can explore more about lathe gears online or in books. Ready to dive deeper? Start learning about lathe setup to make your work even better!

FAQs

What Are The Primary Functions Of A Gear Train In A Gearhead Metal Lathe?

The gear train in a gearhead metal lathe helps control the speed and power of the machine. It allows you to change how fast or slow the lathe spins. This helps you work better and make smoother cuts. The gears also make sure the lathe has enough strength to cut through different materials.

How Does The Gear Ratio In A Gearhead Lathe Affect Spindle Speed And Torque?

The gear ratio in a gearhead lathe changes how fast the spindle spins and how strong it is. A lower gear ratio means the spindle spins slowly but has more power or torque to cut tough materials. A higher gear ratio makes the spindle spin faster but with less power, which is better for softer materials. So, we choose the right gear ratio to match what we need to do.

What Are The Common Types Of Gear Trains Used In Gearhead Metal Lathes, And How Do They Differ?

In gearhead metal lathes, we often see three types of gear trains: simple, compound, and planetary. Simple gear trains use two gears to change speed or direction. Compound gear trains have multiple gears that work together to give us more options. Planetary gear trains have gears that rotate around a center gear, allowing for smooth movement. Each type helps us control how fast or slow the machine works!

How Can Wear And Tear In The Gear Train Components Impact The Performance Of A Metal Lathe?

If the gears in a metal lathe get worn out, they may not work well. This can make the lathe less accurate. You might notice it cuts unevenly or makes strange noises. It can get harder to control how fast or slow it spins. Taking care of these parts helps keep everything running smoothly.

What Maintenance Practices Should Be Performed To Keep The Gearhead Gear Train In Optimal Condition?

To keep the gearhead gear train in good shape, you should check it often for dirt and oil. Clean it carefully using a cloth. Make sure to add oil to the gears to help them move smoothly. If you hear strange noises or see any problems, ask someone to help you fix it. Taking care of it will help it last longer!