Are you fascinated by machines? Do you like working with your hands? If so, a metal lathe might just be your next big adventure. Among all the parts of a lathe, the quill is often overlooked. But what if I told you that the quill is one of the most important pieces?

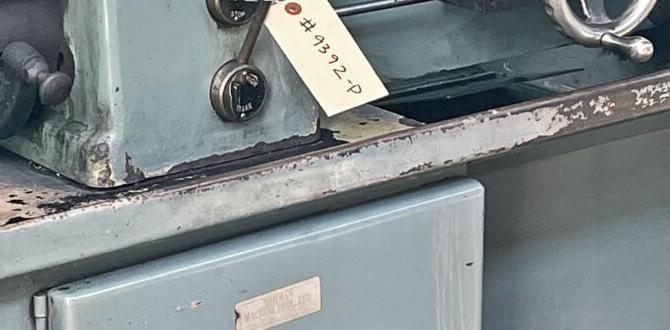

Imagine you’re in a workshop, surrounded by tools and metal pieces. You notice a shiny gearhead metal lathe in the corner. You walk over, eyes sparkling with curiosity. As you start to examine it, one question pops into your mind: how does this machine create such precise shapes?

The secret lies in the quill. This part helps make the metal lathe work smoothly and accurately. Many metalworkers consider the quill an essential feature. Without it, turning and shaping metal would be much harder.

In this article, we will explore the gearhead metal lathe quill. We will uncover its role, its mechanics, and why it matters. Get ready to dive into the world of metalworking!

Gearhead Metal Lathe Quill: Essential Features & Benefits

Understanding the Gearhead Metal Lathe Quill

The gearhead metal lathe quill is crucial for metalworking. It holds the cutting tool securely in place while spinning workpieces. Did you know that adjusting the quill can change the cutting depth? This helps create precise shapes and sizes. Many hobbyists and professionals rely on the quill for accuracy. With the right understanding, you can create projects that impress. Whether you’re a beginner or an expert, knowing your quill makes all the difference!What is a Gearhead Metal Lathe Quill?

Definition and function of a quill in metal lathes. Importance of the quill in machining processes.A quill in a metal lathe is the part that holds the cutting tool. It’s like the superhero cape for your machinery, helping to shape metal into amazing pieces. Its main job is to slide in and out, allowing precise cuts and adjustments. Without the quill, machining would be like trying to bake a cake without a pan—messy and hard to control! So, remember, a quill is key for accurate work and smooth operations.

| Function | Importance |

|---|---|

| Holds the tool | Ensures accuracy |

| Slides for adjustments | Improves efficiency |

| Controls cutting depth | Enhances quality |

In short, a quill is not just a piece of equipment. It’s essential for turning metal into magic!

Components of a Gearhead Metal Lathe Quill

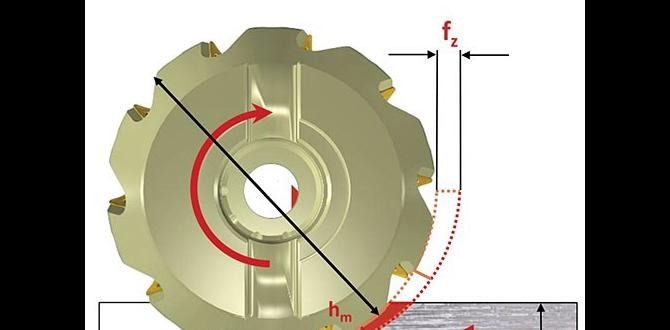

Detailed breakdown of the quill system and its parts. Explanation of how each component contributes to overall performance.A gearhead metal lathe quill has several important parts. Each part works together to help the lathe operate smoothly. Here’s a quick breakdown:

- Quill Sleeve: This holds the cutting tool and allows easy adjustments.

- Lead Screw: It moves the quill up and down for precise cutting.

- Feed Mechanism: This controls how fast the workpiece turns.

- Spindle: It rotates the cutting tool and is crucial for shaping materials.

Each component really helps with the overall performance of the lathe. A well-functioning quill system ensures accuracy in projects. This system helps makers create everything from parts to art with ease.

What is a quill in a lathe?

A quill in a lathe is a part that holds and moves the cutting tool. It helps make precise cuts, making it essential for good work.

Advantages of Gearhead Metal Lathe Quills

Benefits of using a gearhead design over other lathe types. Discussion on efficiency and precision in machining.Using a gearhead metal lathe quill has its perks. First, these quills are super efficient! They help you make parts faster than a cheetah on roller skates. Plus, they offer amazing precision. Your cuts will be so smooth that even butter would be jealous. The design also has fewer moving parts, which means less chance of a hiccup during work. With a gearhead, you get consistent speed options, too. That’s like having a magic button for exactly what you need!

| Advantage | Description |

|---|---|

| Efficiency | Faster production with less downtime. |

| Precision | Accurate cuts for perfect pieces. |

| Fewer Parts | Reduces the chance of breakdowns. |

How to Properly Use a Gearhead Metal Lathe Quill

Stepbystep guide on utilizing the quill for optimal results. Common techniques and best practices in metalworking with the quill.Using a gearhead metal lathe quill is easier than it sounds. First, make sure everything is clean. Dust and grease are not your friends! Next, set your workpiece securely. A loose piece is like a chicken trying to cross the road—unexpected! Now, adjust the quill to the perfect depth according to your project. Remember, depth matters, but don’t go too deep, or you may end up with a mess instead of a masterpiece. Lastly, practice common techniques like boring and drilling. Be steady and watch the chips fly!

| Technique | Best Practice |

|---|---|

| Boring | Use a slow speed for better precision. |

| Drilling | Keep your feed steady to avoid breaking bits. |

So, remember to measure twice, cut once, and bring your best dad jokes for the perfect mix of fun and focus!

Maintenance Tips for Gearhead Metal Lathe Quills

Routine maintenance tasks to ensure longevity and performance. Troubleshooting common issues related to quill operation.Taking care of your gearhead metal lathe quill is essential for its lasting performance. Performing regular maintenance helps catch issues early. Here are some simple tips:

- Clean the quill regularly to remove dust and chips.

- Check the lubrication often. Smooth operation needs good oil.

- Inspect for any signs of wear or damage.

- Adjust settings according to specific tasks for better results.

If you face issues, try these fixes:

- If the quill jams, check for debris inside.

- If it operates slowly, ensure it has enough oil.

Remember, a little care goes a long way in keeping your lathe quill working smoothly!

How do I troubleshoot my quill if it doesn’t move smoothly?

Start by checking for blockages. Clean any debris and ensure lubrication is adequate.

Comparing Gearhead Metal Lathes to Other Types of Lathes

Key differences between gearhead and beltdriven lathes. Pros and cons of each type in various machining applications.When you compare gearhead metal lathes to beltdriven lathes, the differences are clear as day! Gearhead lathes offer quick speed changes with a simple turn of a knob. You could say they’re like your favorite video game—easy and fast! On the other hand, beltdriven lathes need you to swap belts for speed adjustments, which can take time. Think of it as changing tires during a race!

| Type | Pros | Cons |

|---|---|---|

| Gearhead | Quick speed changes | Higher cost |

| Beltdriven | Lower price | Slower adjustments |

In many machining tasks, gearhead lathes shine for their speed and efficiency. But beltdriven lathes have their charm, especially for those on a budget. Just remember, in the world of lathes, there’s no one-size-fits-all!

Choosing the Right Gearhead Metal Lathe Quill for Your Needs

Factors to consider when selecting a quill for specific projects. Recommendations for different types of metalworking tasks.Choosing a quill for your gearhead metal lathe can feel a bit like picking a favorite ice cream flavor—there are so many to choose from! First, think about the type of project you’ll tackle. A sturdy quill is great for heavy cutting while a lighter one is better for smooth finishes. Consider the length and diameter as well; these can really affect your work. Here’s a quick chart to help you decide:

| Project Type | Recommended Quill |

|---|---|

| Heavy Metal Cutting | Heavy-duty Quill |

| Fine Detailing | Precision Quill |

| General Purpose | Standard Quill |

Remember, the right choice can save you time and make your projects turn out better. Don’t hesitate to ask a pro or do some research to find the best fit for your needs!

Conclusion

In summary, a gearhead metal lathe quill is vital for precision work. It helps you adjust cutting tools easily. Understanding its parts will enhance your metalworking skills. We encourage you to explore more about lathes and their features. Practice using a quill to improve your projects. Happy machining!FAQs

What Are The Primary Functions Of A Gearhead Metal Lathe Quill In Machining Operations?The quill on a gearhead metal lathe helps us move the cutting tool up and down. This lets us change the depth of the cut we’re making. It also holds the tool securely while we work. You can adjust the quill to create different shapes and sizes in metal. This makes our machining tasks easier and more accurate.

How Does The Design Of A Gearhead Lathe Quill Differ From That Of A Belt-Driven Lathe?A gearhead lathe uses gears to change speeds. This makes it stronger and better for heavy work. A belt-driven lathe uses belts to move the parts. It’s usually lighter and easier to adjust. So, gearheads are tough, while belt-driven lathes are flexible.

What Maintenance Practices Are Essential For Ensuring The Longevity And Accuracy Of A Gearhead Lathe Quill?To keep your gearhead lathe quill in good shape, clean it often. Use a soft cloth to wipe away dust and oil. Check for any signs of wear like scratches or rust. Make sure to lubricate moving parts with the right oil to keep them running smoothly. Lastly, always store it in a safe, dry place when you’re done using it.

How Can You Troubleshoot Common Issues Related To The Quill Of A Gearhead Metal Lathe?To fix problems with the quill of a gearhead metal lathe, you can start by checking for loose parts. First, make sure everything is tight and secure. If the quill doesn’t move smoothly, clean it and add a little oil. Look for dirt or chips stuck inside, and remove them. If you still have issues, ask a teacher or an expert for help.

In What Scenarios Would A Gearhead Metal Lathe Quill Offer Advantages Over Other Types Of Lathe Spindles?A gearhead metal lathe quill is great when you need to work with tough materials. It can give you more power, which helps cut better. If you want to change speeds quickly, a quill is helpful. It’s also good for projects that need precise work. With this tool, we can finish our work faster and easier.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Primary Functions Of A Gearhead Metal Lathe Quill In Machining Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The quill on a gearhead metal lathe helps us move the cutting tool up and down. This lets us change the depth of the cut we’re making. It also holds the tool securely while we work. You can adjust the quill to create different shapes and sizes in metal. This makes our machining tasks easier and more accurate.”}},{“@type”: “Question”,”name”: “How Does The Design Of A Gearhead Lathe Quill Differ From That Of A Belt-Driven Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A gearhead lathe uses gears to change speeds. This makes it stronger and better for heavy work. A belt-driven lathe uses belts to move the parts. It’s usually lighter and easier to adjust. So, gearheads are tough, while belt-driven lathes are flexible.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Are Essential For Ensuring The Longevity And Accuracy Of A Gearhead Lathe Quill? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your gearhead lathe quill in good shape, clean it often. Use a soft cloth to wipe away dust and oil. Check for any signs of wear like scratches or rust. Make sure to lubricate moving parts with the right oil to keep them running smoothly. Lastly, always store it in a safe, dry place when you’re done using it.”}},{“@type”: “Question”,”name”: “How Can You Troubleshoot Common Issues Related To The Quill Of A Gearhead Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix problems with the quill of a gearhead metal lathe, you can start by checking for loose parts. First, make sure everything is tight and secure. If the quill doesn’t move smoothly, clean it and add a little oil. Look for dirt or chips stuck inside, and remove them. If you still have issues, ask a teacher or an expert for help.”}},{“@type”: “Question”,”name”: “In What Scenarios Would A Gearhead Metal Lathe Quill Offer Advantages Over Other Types Of Lathe Spindles? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A gearhead metal lathe quill is great when you need to work with tough materials. It can give you more power, which helps cut better. If you want to change speeds quickly, a quill is helpful. It’s also good for projects that need precise work. With this tool, we can finish our work faster and easier.”}}]}