Have you ever wondered how artists turn big blocks of metal into amazing shapes? It often starts with a heavy-duty metal lathe. These powerful machines use torque to spin and shape metal with incredible precision.

Imagine working in a workshop, hearing the sound of the lathe whirring. You have a big piece of metal, and you need to carve it into something special. A heavy-duty metal lathe makes this possible. It can easily tackle tough materials that smaller machines can’t handle.

Did you know that the amount of torque a lathe produces is key to its performance? Torque helps the machine cut through thick metal smoothly. This means you can create strong and detailed parts for projects like cars, planes, or even art pieces!

As we dive into this article, we’ll explore how heavy-duty metal lathes work and why torque is so important. Get ready to discover the magic of shaping metal and the secrets behind these powerful machines!

Heavy Duty Metal Lathe Torque: Power And Precision Combined

Heavy Duty Metal Lathe Torque

Heavy duty metal lathes are powerful tools that deliver impressive torque. This makes them perfect for shaping and cutting tough materials. Did you know a lathe can spin at different speeds? This lets you handle various tasks effectively. The torque helps maintain control, even with larger pieces. Understanding how torque works can help you choose the right lathe for your project. Think it’s just for professionals? Many hobbyists find it invaluable! Discovering the right torque can make your crafting a breeze.What is a Heavy Duty Metal Lathe?

Definition and purpose of heavy duty metal lathes. Key features that distinguish them from standard lathes.A heavy duty metal lathe is a powerful tool for shaping metal. It spins metal pieces at high speed. This helps in turning them into specific shapes. Heavy duty lathes can handle large and tough projects, unlike standard lathes. They are built stronger, allowing them to work on big jobs. Key features include:

- Sturdy frame for strength

- High torque for tough materials

- Large working area

- Advanced controls for precision

What are the differences between heavy duty and standard lathes?

Heavy duty lathes have a stronger build and more power. Standard lathes are for lighter tasks. In fact, heavy duty lathes can manage tough metals and big pieces that smaller ones cannot.

Importance of Torque in Metal Lathes

Explanation of torque and its role in machining. How torque affects performance and efficiency.Torque is the turning force in metal lathes. It helps shape materials like metal and wood. More torque means the machine can handle tough jobs. This leads to better performance and efficiency. High torque allows the lathe to work faster without wasting energy. Think about riding a bike uphill; more torque helps you climb better.

- Improves cutting speed.

- Reduces wear on tools.

- Increases product quality.

Why is torque key for metal lathes?

Torque is essential because it directly impacts how well the lathe performs. The right amount of torque leads to smoother operations and longer tool life.

Factors Influencing Torque Output

Design and construction of the lathe. Types of motors and their torque capacities. Importance of gearing and transmission systems.Many things affect how much torque a heavy duty metal lathe can produce. First, the design and construction of the lathe itself matter a lot. A strong frame can hold more power. Next, the type of motor used is vital. Motors with higher torque capacities can perform tougher jobs. Finally, gearing and transmission systems play a crucial role too. They help transfer power better, making work smoother and faster.

What affects the torque output of a metal lathe?

Three main factors influence torque output:

- Design and construction of the lathe

- Types of motors and their torque capacities

- Importance of gearing and transmission systems

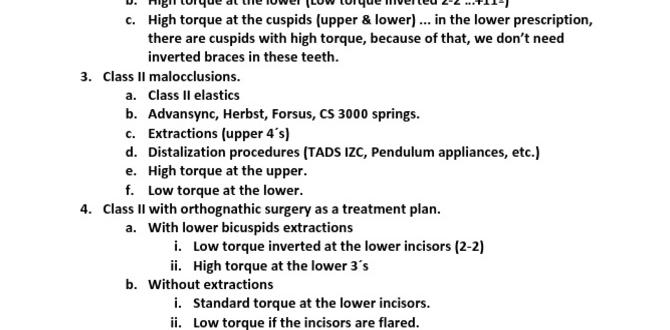

Torque Specifications for Heavy Duty Lathes

Common torque ratings and what they mean. Standards and measurements for evaluating torque.Torque helps heavy duty lathes spin fast and cut better. But what does that mean? Common torque ratings tell us how much twist a lathe can handle. For a serious machine, ratings may range from 100 to 500 Nm. It’s like comparing a bike’s gears to a race car’s. Not all torque is created equal, though; some lathes will make your projects smooth while others might just send your projects flying! Let’s look at some common ratings:

| Torque Rating (Nm) | Use |

|---|---|

| 100 | Light projects |

| 250 | Medium projects |

| 500 | Heavy projects |

Measuring torque uses standard tools and units. The most common ones are Newton-meters (Nm). Think of it as measuring how hard you can twist your soda bottle cap. The higher the number, the stronger the lathe! Want your lathe to work like a champ? Keep the torque specs in mind!

Choosing the Right Heavy Duty Metal Lathe

Key considerations for selecting a lathe based on torque needs. Comparing torque capabilities across brands and models.Selecting a lathe involves a few important choices. First, consider the torque you need for your projects. High torque is vital for tough materials. Next, compare the torque capabilities of different brands and models. Some brands are better for heavy-duty tasks than others. Checking reviews can help you find the right tool for you.

What should I look for in torque for metal lathes?

Look for high torque ratings to handle hard materials easily. Make sure the lathe can support the size and weight of the items you’ll work on.

Key factors to consider:

- Torque requirements for specific materials

- Brand reputation and model reviews

- Weight capacity of the lathe

Maintaining Optimal Torque in Metal Lathes

Best practices for maintenance and adjustments. Common issues that can affect torque performance.To keep your metal lathe working well, practice good maintenance. Regular checks can prevent many issues. You should also make simple adjustments to maintain the correct torque. Here are some best practices:

- Clean parts often.

- Lubricate moving areas.

- Check belts for wear.

Common problems that can affect torque include:

- Loose bolts.

- Worn gears.

- Dirty components.

By following these tips, you ensure your heavy duty metal lathe stays in top shape.

What are the best maintenance tips for metal lathes?

Regular maintenance is key. Clean and lubricate regularly. Check for loose parts and tighten them. This keeps torque optimal.

Applications of Heavy Duty Metal Lathes

Industries that commonly utilize heavy duty lathes. Examples of projects and products made with these lathes.Many industries rely on heavy duty metal lathes. These machines are powerful and can handle tough jobs. They are used in:

- Aerospace for making aircraft parts.

- Automotive to create engine components.

- Shipbuilding for large propellers.

- Manufacturing to produce tools and fixtures.

Some projects include creating gears, shafts, and complex shapes. Heavy duty metal lathes help make products that keep our world moving.

What do heavy duty metal lathes make?

Heavy duty metal lathes make gears, axles, and custom parts for machines. They shape and cut metal precisely.

Latest Innovations in Heavy Duty Metal Lathes

Advances in technology affecting torque and performance. Future trends in heavy duty lathe design and capabilities.Technology is zooming ahead like a race car! Heavy duty metal lathes are getting stronger and smarter. New designs improve torque and performance, making work easier than ever. Imagine a lathe that adjusts itself while you nap—maybe that’s a stretch, but close enough! Future models might even come with smart features, like predicting when parts need fixing. Hold onto your helmets; the future looks fascinating!

| Innovation | Description |

|---|---|

| Smart Technology | Automatic adjustments for peak performance. |

| Eco-Friendly Designs | Energy-efficient models for greener workspaces. |

| Enhanced Safety Features | Built-in alerts to prevent accidents. |

Conclusion

In conclusion, heavy duty metal lathes are powerful tools that require strong torque to work effectively. Understanding torque helps you choose the right lathe for your projects. Always look for robust construction and high torque ratings when purchasing. For more tips and guidance, dive into articles about lathe selection and usage. Let’s create amazing things together with the right tools!FAQs

Sure! Here Are Five Questions Related To Heavy Duty Metal Lathe Torque:Sure! Let’s talk about heavy-duty metal lathes and torque. Torque is how much turning power a machine has. A heavy-duty metal lathe uses a lot of torque to cut tough metal. This helps it shape and smooth metal pieces. You can think of it like a strong arm turning a big wheel!

Sure! Please tell me what question you would like me to answer.

What Factors Determine The Torque Requirements For A Heavy Duty Metal Lathe During Different Machining Operations?The torque needed for a heavy-duty metal lathe depends on a few things. First, it depends on how thick or hard the metal is. Thicker and harder metals need more power to cut. Next, the type of cutting tool you use matters. Some tools need more force to work well. Finally, the speed you choose for the lathe can also change how much torque you need.

How Can Excessive Torque Affect The Performance And Longevity Of A Heavy Duty Metal Lathe?Excessive torque is when a machine gets too much twisting power. This can cause the heavy-duty metal lathe to work poorly. Parts might wear out or break faster. We want our machines to last a long time, so we have to be careful with the torque. If we use the right amount, the lathe will run smoothly and last longer.

What Are The Typical Torque Specifications For Heavy Duty Metal Lathes, And How Do They Vary Between Different Models?Heavy-duty metal lathes usually need a torque of about 50 to 200 foot-pounds. This helps keep them running well. Different models might need more or less torque based on their size and power. When choosing a lathe, you should check the manual for exact numbers. Each model is unique, so we need to compare them carefully.

How Is Torque Measured In Heavy Duty Metal Lathes, And What Tools Or Methods Are Used For Accurate Measurement?We measure torque in heavy-duty metal lathes using a special tool called a torque wrench. This tool checks how much turning force the lathe uses to spin metal. We can also use a dynamometer, which measures power and torque at the same time. By using these tools, we can make sure the lathe runs safely and correctly.

What Role Does Torque Play In Achieving Precise Tolerances And Surface Finishes When Machining Materials On A Heavy Duty Metal Lathe?Torque is the twisting force that helps a heavy-duty metal lathe cut materials smoothly. When you have the right amount of torque, your cuts are clean and precise. This means your parts fit together well and look good. If the torque is too low or too high, the cuts can be rough or uneven. So, good torque helps us make better parts!