Have you ever watched a metal lathe in action? It’s fascinating! A hobbyist metal lathe lets you create amazing parts with metal. But did you know you can design those parts before making them? That’s where CAD design comes into play.

Using CAD, or computer-aided design, helps turn your ideas into real objects. Imagine sketching your metal creations on a computer screen. With hobbyist metal lathe CAD design, you can make your dreams a reality!

Picture this: You have a vision of a custom metal tool. Instead of guessing, you can draw it first. This saves time and helps avoid mistakes. Plus, CAD programs are often easy to use.

As you learn about hobbyist metal lathe CAD design, you open doors to countless possibilities. What will you create next? A unique part for your project or a gift for a friend? The choice is yours, and the adventure is just beginning!

Hobbyist Metal Lathe Cad Design: Unleashing Creativity And Precision

Hobbyist Metal Lathe CAD Design

Hobbyist metal lathe CAD design opens new doors for creativity. Imagine crafting your own parts with precision! CAD software helps plan 3D models and visualize projects before building. It makes mistakes easier to spot. Want to create something cool like a custom tool or an art piece? Learning to use CAD can turn your ideas into reality. Plus, it’s fun to learn new skills. Who knew designing could be this exciting?Understanding the Basics of Metal Lathes

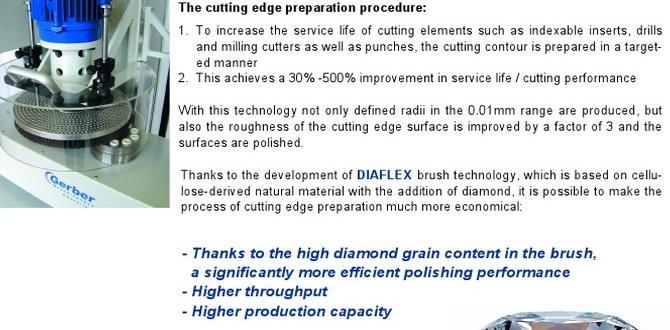

Definition and types of metal lathes. Common applications in hobby projects.Metal lathes are machines that shape metal. They work by rotating the metal while a tool cuts it. There are two main types: traditional lathes and CNC lathes. Traditional lathes are operated by hand, while CNC lathes use computers.

Hobbyists often use metal lathes for fun projects. Common uses include:

- Making small parts for models

- Creating custom tools

- Designing unique gifts

Metal lathes are great for turning ideas into reality! Whether for fun or learning, they inspire creativity.

What can you make with a metal lathe?

You can make many things, like custom screws or decorative pieces. The choices are endless!

Essential CAD Design Principles for Metal Lathes

Importance of precision in designs. Understanding tolerances and fits.Designing with precision is key for successful projects. Without it, pieces may not fit together well. Tolerances refer to how much size can vary. If parts are too tight, they won’t assemble. If too loose, they can break or wobble. It is important to know the right fit. Here are some essential points:

- Measure carefully.

- Choose the right materials.

- Use accurate tools.

Learning these principles makes designs effective. Remember, tight tolerances mean careful work. Good designs bring better results!

Why is precision important in CAD design?

Precision ensures that parts fit and work well together, making the final product efficient and reliable.

What are tolerances and fits?

Tolerances define the allowed size variations, while fits determine how snugly parts come together.

Step-by-Step Guide to Creating a Metal Lathe Design

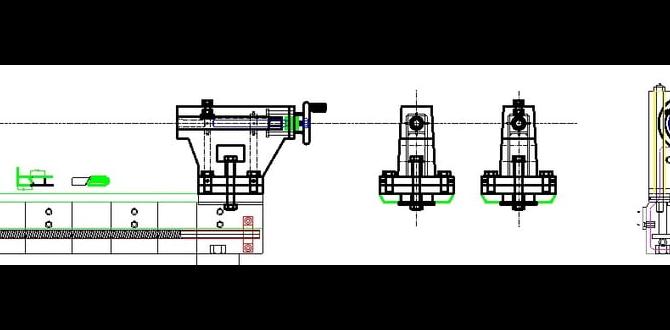

Initial conceptualization and sketching. Creating a 2D design in CAD software. Transitioning from 2D to 3D modeling.Start by thinking about what your metal lathe will look like. Draw some sketches showing your ideas. Next, open your CAD software and create a simple 2D design of your lathe. This helps you see how parts will fit together. After that, turn your 2D design into a 3D model. This makes it easier to visualize and understand your project.

- Initial sketching is fun and creative.

- 2D designs in CAD are like blueprints.

- 3D modeling gives you a complete view.

What is the best way to start a CAD design for metal lathes?

Start by making sketches and visualizing your design ideas. This makes the CAD process easier and more fun!Common Mistakes to Avoid in CAD Design for Metal Lathes

Frequent design errors that lead to machining issues. Tips for troubleshooting design problems.Design mistakes can cause big problems when using a metal lathe. Common errors include wrong measurements and unclear drawings. These issues can lead to poor cuts or damaged parts. To avoid these problems, keep your design simple and check it twice. Always use the right tools to measure and create your CAD designs. Here are some tips for troubleshooting:

- Always double-check measurements.

- Use clear labels on designs.

- Test designs in a virtual environment first.

Fixing small mistakes early can save you time and material. Remember, practice makes perfect!

What are common CAD design errors for metal lathes?

Common errors include incorrect measurements, unclear pathways, and not considering tool size. Ensuring you design with clarity helps avoid these mistakes.

How can I troubleshoot CAD design problems?

Check your measurements, revise unclear labels, and always create a prototype. These steps can help you catch mistakes before machining begins.

Tips for Optimizing Your CAD Design Workflow

Strategies for efficient design processes. Utilizing templates and libraries in CAD software.To make your CAD design process smoother, think about using templates and libraries. They can save you precious time. Need to draw shapes repeatedly? Just grab a template! Libraries are like your toolbox; they hold ready-made parts you can use anytime. Want a table to show how much faster this could be?

| Method | Time Saved |

|---|---|

| Using Templates | Up to 50% |

| Utilizing Libraries | 30% to 70% |

Think of CAD design as cooking. Would you chop veggies every time you make a salad? Nope! Use your templates like a chef uses a knife. With these strategies, you’ll whip up designs faster than a rabbit on roller skates!

Showcasing Your Metal Lathe Projects: Best Practices

How to present and document your designs. Sharing designs with the community for feedback.Documenting your metal lathe projects helps others see your hard work. Take clear photos of your designs. Write instructions that are easy to follow. Share these on websites or forums where metalworkers gather. This will help you get useful feedback and connect with others who love this hobby.

- Use bright lighting for photos.

- Write each step clearly.

- Ask questions to spark discussion.

How can I share my designs with others?

Create posts with images and steps for clear sharing. Be open to feedback. Engaging with the community can help you improve your skills.

Future Trends in Hobbyist Metal Lathe CAD Design

Emerging technologies and innovations. Predictions for the future of CAD in metalworking hobbyists.New tools are popping up in the world of CAD for metal lathes. Innovations like 3D printing and smart software are making it easier for hobbyists to create amazing designs. For example, hobbyists can soon use a program that predicts the best cutting paths. Imagine a machine that says, “Hey, I know how to make that part faster!” Future hobbyists might even program their lathes with a few silly jokes to lighten the mood while they work. Here’s a quick look at what’s ahead:

| Trend | Description |

|---|---|

| AI Integration | Machines talking to each other? Yes, please! AI could help make smarter decisions. |

| Virtual Reality | Imagine designing in a VR world. You might feel like a wizard of metal! |

| Eco-Friendly Practices | More hobbyists may choose green methods. Saving the planet while creating? Double win! |

The future looks bright for hobbyist metal lathe CAD design. Are you ready to join the adventure?

Conclusion

In conclusion, hobbyist metal lathe CAD design is a fun way to create custom parts. You can improve your skills by using user-friendly software. Start with simple projects and gradually take on more complex designs. Explore online tutorials and join communities to learn from others. Dive into this exciting hobby and unleash your creativity today!FAQs

Sure! Here Are Five Questions Related To Hobbyist Metal Lathe Cad Design:Sure! Here are five questions about designing parts for a metal lathe using CAD, which means Computer-Aided Design. 1. **What is a metal lathe?** A metal lathe is a tool that spins metal to shape it. You can make round pieces like rods or discs. 2. **Why use CAD for the metal lathe?** CAD helps you design parts on a computer before making them. It makes planning easier and mistakes fewer. 3. **What can you make with a metal lathe?** You can create many things like handles, gears, and even toys. Your imagination can help you create cool projects! 4. **How do we start a CAD design?** First, think of what you want to make. Then, draw it on the computer. 5. **What materials can we use for our projects?** We can use different types of metal, like aluminum or steel. Each metal makes unique items!

Sure! Please provide the question you want me to answer, and I’ll be happy to help.

What Are The Key Features To Consider When Designing A Metal Lathe In Cad For Hobbyist Applications?When designing a metal lathe in CAD for hobbyist use, you should think about some important features. First, make sure the lathe is easy to use and safe. You want it to have a sturdy base so it doesn’t wobble while you work. Next, include adjustable parts so you can make different shapes and sizes. Finally, think about how you will power the lathe, like with a motor or by hand. These features will help you create a great tool!

How Can You Optimize A Cad Design For A Metal Lathe To Ensure Ease Of Assembly And Maintenance?To make a CAD design for a metal lathe easy to put together and fix, we can follow a few steps. First, we should make sure all parts fit together well without forcing them. Next, we can use bigger holes for screws so they are easy to reach. We can also add labels to each piece, so we know where they go. Finally, keep the design simple with fewer parts to make everything easier!

What Cad Software Is Most Commonly Used By Hobbyists For Designing Metal Lathes, And What Are Its Strengths?Many hobbyists use FreeCAD for designing metal lathes. FreeCAD is free to download, and it’s easy to learn. You can create 3D models and parts with it. Its tools let you make precise designs, which is great for metal work. Plus, you can use it on different computers, which is super helpful!

How Do You Incorporate Tooling And Machining Tolerances In Your Cad Design For A Metal Lathe?When I design in CAD for a metal lathe, I think about how precise the parts need to be. I use special tools in the program to set these exact measurements. This helps ensure that when we make the metal parts, they fit together perfectly. I also check the design often to make sure everything is correct and fits within the required limits. Making adjustments helps us avoid mistakes and keeps the pieces working well together.

What Are Some Common Challenges Faced By Hobbyists When Creating Cad Models For Custom Metal Lathe Components, And How Can They Be Overcome?Hobbyists often face challenges like not knowing how to use CAD software, making mistakes in measurements, and not understanding material limits. You can overcome these problems by watching tutorial videos and practicing. Always double-check your measurements before starting and read about the materials you plan to use. Joining a local group or online forum can also help, as you can ask questions and get tips from others.