Have you ever watched a metal lathe in action? It’s fascinating! A hobbyist metal lathe threading dial is a key tool that helps you make perfect threads. When you turn it, you control how the lathe cuts metal. This little device can make a big difference in your projects.

Imagine creating your own metal parts. You start with a dream and some metal. Then, with the right tools and skills, you can build something amazing. The threading dial, although small, has a huge job. It makes sure every cut is just right. But how does it work?

Did you know that many expert machinists started as hobbyists? They learned by experimenting with their lathes. The threading dial guided them, helping them improve their skills. With patience and practice, they turned their hobbies into passion. What if you could do the same?

In this article, we will explore the importance of the hobbyist metal lathe threading dial. You will discover tips to use it effectively and enhance your metalworking skills. Get ready to dig into the world of metal lathes!

Hobbyist Metal Lathe Threading Dial: A Comprehensive Guide

Hobbyist Metal Lathe Threading Dial

A hobbyist metal lathe threading dial is an essential tool for precise machining. It helps users create accurate threads on metal projects, ensuring the fit is just right. Did you know that using a threading dial can save time and reduce mistakes? For anyone new to metalworking, this tool offers great value. Imagine mastering threading techniques faster and with more confidence. Whether you’re a beginner or an experienced craftsman, a threading dial can be a game changer!Understanding the Basics of Metal Lathes

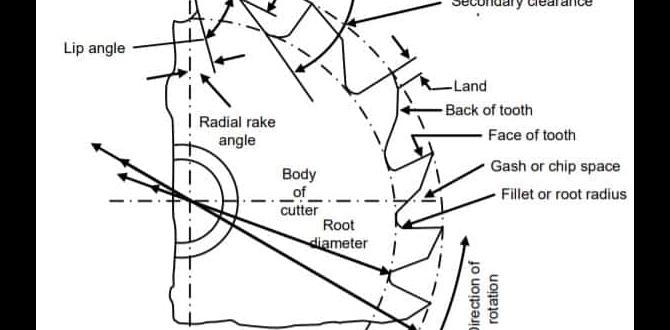

Definition and purpose of metal lathes. Key components and how they function together.Metal lathes are machines that shape metal pieces. They spin the metal while tools cut into it. This creates different shapes and sizes. Key parts include the bed, headstock, and tailstock. Each part works together smoothly. The bed supports the lathe. The headstock holds the spinning part and the tailstock can move for different tasks.

What are the main features of metal lathes?

The main features include the ability to make precise shapes, adjustable speeds, and easy tool changes. These features help hobbyists create amazing projects.

- Bed: Supports the entire lathe.

- Headstock: Holds and spins the workpiece.

- Tailstock: Supports tools and adjusts positions.

The Importance of Threading Dials in Metalworking

Role of threading dials in achieving accurate threads. Comparison between threading dials and other methods.Threading dials are essential in metalworking. They help create accurate threads, and we all know how tricky that can be—like trying to thread a needle during an earthquake! The dial guides you, ensuring your work is precise. Compared to other methods, threading dials are simpler and more reliable. Here’s a quick comparison:

| Method | Accuracy | Ease of Use |

|---|---|---|

| Threading Dial | High | Easy |

| Measuring Tape | Medium | Hard |

| Freehand | Low | Very Hard |

For those who love precision, a threading dial beats other methods hands down. A wise person once said, “Measure twice, thread once!” Let’s be honest, that’s easier with a trusty threading dial by your side!

Features to Look for in a Hobbyist Metal Lathe Threading Dial

Material and durability considerations. Types of threading dials available (manual vs. digital).Choosing the right hobbyist metal lathe threading dial is important. Look for materials that are strong and last long, like steel or aluminum. These dials should fit well on your lathe and withstand regular use.

There are two main types of threading dials:

- Manual: These are simple and easy to use, ideal for beginners.

- Digital: These offer precise readings and can help you cut threads more accurately.

Think about what fits your needs best before you purchase.

What is a threading dial used for?

A threading dial helps you line up cuts when making threads in metal. It’s essential for good results.

Step-by-Step Guide to Installing a Threading Dial

Necessary tools and materials for installation. Detailed installation process with diagrams or images.Installing a threading dial on your metal lathe is an exciting project. First, gather the necessary tools and materials. You’ll need:

- Wrench

- Screwdriver

- Drill

- Measuring tape

- Threading dial kit

1. Measure where to place the dial.

2. Drill holes and secure it with screws.

3. Connect the dial to the lathe carefully.

4. Check alignment for accuracy!

Use diagrams or images to guide you during each step.

What tools do I need to install a threading dial?

You need a wrench, screwdriver, drill, measuring tape, and a threading dial kit.

Common Techniques for Using a Threading Dial Effectively

Tips for aligning the workpiece and threading dial. Essential threading techniques for beginners.Using a threading dial correctly can really level up your metal lathe skills. First, make sure to align your workpiece properly. If not, you might end up threading more like a spaghetti monster than a smooth cylinder! For beginners, a common method is to place the dial close to the tool. This helps you track each turn more easily. Here’s a quick guide:

| Tip | Description |

|---|---|

| Check Alignment | Ensure the workpiece is straight and secure to avoid misthreads. |

| Start Slow | Begin with fewer threads, then gain confidence before speeding up! |

| Practice Makes Perfect | The more you use the lathe, the better you’ll become. It’s like riding a bike! |

Each of these tips can help you create clean and precise threads. Don’t forget—practice is key. Plus, it’s a great excuse to play with cool tools!

Troubleshooting Common Issues with Threading Dials

Identifying and resolving misalignments. Ensuring consistent thread depth and pitch.Dealing with threading dial issues can feel like trying to juggle while riding a unicycle. First, check for misalignment. If the threading dial isn’t lined up right, your threads will be all wobbly, like an unsteady puppy. Adjust the dial and double-check its fit. Next, ensure you maintain a consistent thread depth and pitch. Even a tiny difference in measurements can lead to a big mess. Keep your tools handy to avoid ‘guesswork.’ Enjoy the process, and remember: happy threading leads to happy projects!

| Issue | Solution |

|---|---|

| Misalignment | Realign the threading dial carefully. |

| Variable Depth | Use calipers to measure depth consistently. |

Enhancing Your Metalworking Skills with Threading Dials

Suggested projects to practice threading techniques. Resources for further learning and skill development.Want to up your metalworking game? Try some fun projects! Make small nuts and bolts or create a custom handle for a drawer. These tasks let you practice your threading skills and show off your work. Check out online forums or YouTube channels dedicated to metalworking for great ideas and tutorials. They can guide you like a trusty sidekick!

| Project | Description |

|---|---|

| Bolts | Simple and useful, perfect for practice! |

| Drawer Handle | Creates a unique touch for your furniture. |

For extra learning, there are many books and websites packed with tips and tricks. You’ll be threading like a pro in no time!

Conclusion

In conclusion, a hobbyist metal lathe threading dial is a valuable tool for accurate threading. It helps you make precise measurements and improve your projects. With practice, you can create stronger, better-fitting parts. Start by exploring different threading techniques online. Keep learning and experimenting to enhance your skills. Happy turning!FAQs

Sure! Here Are Five Questions Related To Hobbyist Metal Lathe Threading Dials:Sure! Here are five questions about hobbyist metal lathe threading dials you might ask: 1. What is a threading dial? 2. How does a threading dial help us? 3. Can I use a threading dial for all my projects? 4. What materials are used to make threading dials? 5. How do we set up a threading dial on a lathe? Let me know if you want to learn more!

Of course! Just ask your question, and I’ll provide a short answer for you.

What Is The Purpose Of A Threading Dial On A Metal Lathe, And How Does It Assist In The Threading Process?A threading dial on a metal lathe helps you cut threads on a piece of metal. It shows you when to stop the machine and move the tool back for the next cut. This makes it easier to line up the cuts perfectly. Using the dial helps create neat and even threads. Overall, it ensures the threading process goes smoothly.

How Do You Properly Set Up And Calibrate A Threading Dial For Accurate Threading On A Metal Lathe?To set up the threading dial, first, make sure the lathe is off. Then, bring the tool to touch the metal where you want to thread. You turn the threading dial until the needle points to zero. Slowly turn the lathe on, and then move the carriage until the needle reaches zero again. You are now ready to cut threads accurately!

What Are Some Common Troubleshooting Tips For When A Threading Dial Does Not Provide Accurate Results During Operation?If your threading dial isn’t working right, first check if it’s clean and free of dirt. Sometimes, you might need to adjust its settings. Make sure the machine is threading at the right speed. If it still does not work, try turning the dial slowly to see if that helps. Finally, you can ask someone more experienced for help if you are still having trouble.

How Does The Type Of Threading Dial—Such As A 4-Lead Or A 6-Lead Dial—Affect The Threading Process On A Lathe?The type of threading dial changes how you cut threads on a lathe. A 4-lead dial is for faster threading. A 6-lead dial lets you cut threads more smoothly. Choosing the right dial helps make your work easier and more accurate. So, knowing which one to use is important!

What Are The Key Differences Between Using A Threading Dial And Other Methods Of Threading, Such As Using A Tailstock Die Or A Tap?A threading dial helps you align the tool to cut threads easily. It shows you the right spot to start. Using a tailstock die means you twist a tool by hand, which can be harder. A tap lets you make holes with threads, but it’s different from cutting them on a rod. The threading dial makes everything faster and helps you get better results!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Hobbyist Metal Lathe Threading Dials:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about hobbyist metal lathe threading dials you might ask: 1. What is a threading dial? 2. How does a threading dial help us? 3. Can I use a threading dial for all my projects? 4. What materials are used to make threading dials? 5. How do we set up a threading dial on a lathe? Let me know if you want to learn more! “}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Just ask your question, and I’ll provide a short answer for you.”}},{“@type”: “Question”,”name”: “What Is The Purpose Of A Threading Dial On A Metal Lathe, And How Does It Assist In The Threading Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A threading dial on a metal lathe helps you cut threads on a piece of metal. It shows you when to stop the machine and move the tool back for the next cut. This makes it easier to line up the cuts perfectly. Using the dial helps create neat and even threads. Overall, it ensures the threading process goes smoothly.”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up And Calibrate A Threading Dial For Accurate Threading On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up the threading dial, first, make sure the lathe is off. Then, bring the tool to touch the metal where you want to thread. You turn the threading dial until the needle points to zero. Slowly turn the lathe on, and then move the carriage until the needle reaches zero again. You are now ready to cut threads accurately!”}},{“@type”: “Question”,”name”: “What Are Some Common Troubleshooting Tips For When A Threading Dial Does Not Provide Accurate Results During Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your threading dial isn’t working right, first check if it’s clean and free of dirt. Sometimes, you might need to adjust its settings. Make sure the machine is threading at the right speed. If it still does not work, try turning the dial slowly to see if that helps. Finally, you can ask someone more experienced for help if you are still having trouble.”}},{“@type”: “Question”,”name”: “How Does The Type Of Threading Dial—Such As A 4-Lead Or A 6-Lead Dial—Affect The Threading Process On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The type of threading dial changes how you cut threads on a lathe. A 4-lead dial is for faster threading. A 6-lead dial lets you cut threads more smoothly. Choosing the right dial helps make your work easier and more accurate. So, knowing which one to use is important!”}},{“@type”: “Question”,”name”: “What Are The Key Differences Between Using A Threading Dial And Other Methods Of Threading, Such As Using A Tailstock Die Or A Tap?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A threading dial helps you align the tool to cut threads easily. It shows you the right spot to start. Using a tailstock die means you twist a tool by hand, which can be harder. A tap lets you make holes with threads, but it’s different from cutting them on a rod. The threading dial makes everything faster and helps you get better results!”}}]}