Have you ever thought about how metalworking hobbies can transform your ideas into real objects? Many hobbyists enjoy using metal lathes to create projects, from simple tools to intricate designs. However, wiring these machines can be tricky. That’s where a good hobbyist metal lathe wiring diagram comes in handy.

Imagine you’re in your garage, excited to start your latest project. You have the tools, the materials, but something feels off. Why isn’t your lathe running? A well-detailed wiring diagram can help you troubleshoot issues and keep your project on track.

Did you know that many metal lathes have similar wiring setups? That means a basic hobbyist metal lathe wiring diagram can support many types of machines. With a clear diagram, you gain the confidence to wire your lathe correctly.

Let’s explore the world of hobbyist metal lathe wiring diagrams. They can lead you to successful projects and even spark a new passion in metalworking!

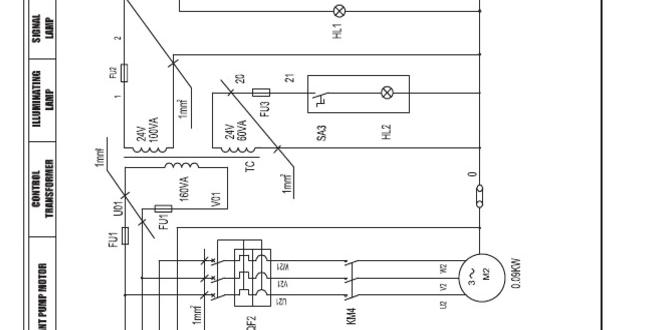

Hobbyist Metal Lathe Wiring Diagram: A Comprehensive Guide **Main Article:** When Diving Into The World Of Metalworking, Understanding Your Equipment Is Crucial, And One Of The Key Areas To Focus On Is The Wiring Of Your Hobbyist Metal Lathe. Proper Wiring Ensures That Your Machine Runs Smoothly And Safely, Providing You With The Optimal Conditions For Crafting Your Projects. In This Article, We Will Explore The Essential Components Of A Hobbyist Metal Lathe Wiring Diagram And Offer Tips For Effective Implementation. Understanding Your Hobbyist Metal Lathe A Metal Lathe Is A Versatile Tool Used To Shape Various Metal Materials Through The Process Of Spinning Them Against A Cutting Tool. Hobbyists Often Engage In Metalworking As A Pastime Or Small-Scale Production, Making It Essential To Have A Reliable And Well-Wired Machine. Components Of A Hobbyist Metal Lathe Wiring Diagram 1. **Power Supply:** Your Lathe Will Require A Specific Power Input, Typically 120V Or 240V, Depending On The Model. Make Sure Your Wiring Supports The Required Voltage. 2. **Motor Connections:** The Motor Is The Heart Of Your Lathe. A Proper Wiring Diagram Will Indicate How To Connect The Motor To The Power Supply And Any Control Switches. 3. **Control Switches:** Safety Is A Priority, And Control Switches Should Be Easily Accessible. A Wiring Diagram Will Show You Where To Place Emergency Stops And Speed Controls. 4. **Grounding:** Proper Grounding Is Essential To Prevent Electrical Shocks. Ensure The Diagram Includes Grounding Points For Safety. 5. **Fuses And Circuit Breakers:** To Safeguard Your Equipment, Your Wiring Diagram Should Feature Fuses Or Circuit Breakers That Will Protect Against Electrical Overload. Designing Your Wiring Diagram Creating A Wiring Diagram Can Seem Daunting, But Following These Steps Can Simplify The Process: 1. **Refer To Manufacturer Manuals:** Begin By Checking The Manual Of Your Specific Lathe Model For Wiring Recommendations And Diagrams. 2. **Sketch Your Diagram:** Use Graph Paper Or Digital Design Tools To Sketch The Layout, Ensuring Clarity And Organization. 3. **Label Components Clearly:** Use Clear Labels For Each Component To Avoid Confusion During Installation. 4. **Double-Check Connections:** Before Finalizing Your Wiring, Double-Check Each Connection Against The Diagram To Ensure Accuracy. Conclusion Mastering The Wiring Of Your Hobbyist Metal Lathe Is Vital For Optimal Performance And Safety. With The Right Wiring Diagram, You Can Ensure That Your Machine Runs Efficiently, Allowing You To Focus On Your Creative Projects Without Worry. Always Remember To Consult Professional Resources Or Seek Assistance If You Encounter Challenges During The Wiring Process. Happy Turning!

Understanding Hobbyist Metal Lathe Wiring Diagrams

Wiring diagrams for hobbyist metal lathes show how to connect electrical components. They reveal how to power motors and safety features. Knowing this helps hobbyists avoid mistakes. You might wonder how a simple diagram can save you time and money. In fact, understanding wiring can lead to smoother projects and fewer headaches. Discovering these diagrams is like finding a treasure map that leads to better results in your metalworking adventures!Understanding Metal Lathe Basics

Definition and purpose of a metal lathe. Key components of a metal lathe.A metal lathe is a machine used to shape materials like metal or wood. It spins the material while a cutting tool shapes it. This process makes precise parts for many projects. Key components of a metal lathe include:

- Bed: This is the main support of the lathe.

- Headstock: It holds the spindle that spins the material.

- Tailstock: This supports the other end of the material.

- Cross Slide: It moves the cutting tool side to side.

These parts work together to help create accurate shapes. Metal lathes are great for hobbyists and professionals alike.

What are the uses of a metal lathe?

A metal lathe is used for many tasks. People use it to create parts for cars, tools, and models. It can also help in making artistic items!

Importance of Proper Wiring in Metal Lathes

Impacts on performance and safety. Common issues with improper wiring.Wiring your metal lathe correctly is super important. It can make your machine run smoothly or turn it into a clunky paperweight. Improper wiring can lead to poor performance, causing parts to wear out faster. Safety is also a big deal! Bad wiring can create electrical hazards, like shocks or fires. Who wants that? Let’s take a peek at some common issues:

| Issue | Impact |

|---|---|

| Loose connections | Causes flickering power |

| Incorrect voltage | Overheats the motor |

| Exposed wires | Risk of shocks |

So, remember: a happy lathe equals happy projects. No one wants to fight with their tools, right?

Essential Tools and Materials for Wiring

List of tools needed for wiring a metal lathe. Recommended materials and safety equipment.Wiring a metal lathe requires some key tools and materials. Here’s a simple list to help you get started:

- Wire Stripper: Used to remove insulation from wires.

- Screwdrivers: Needed for tightening screws.

- Voltage Tester: Checks if wires carry electricity.

- Heat Shrink Tubing: Protects connections from moisture.

- Electrical Tape: Insulates and secures wires.

Don’t forget your safety gear! Wear gloves and safety glasses to protect yourself.

What materials do I need for wiring a metal lathe?

You need copper wire, connectors, and insulators. These materials ensure a safe and effective connection.

Step-by-Step Wiring Instructions

Detailed wiring diagram and instructions. Troubleshooting common wiring problems.First things first, let’s tackle the wiring! Start by following the detailed wiring diagram that came with your metal lathe. This diagram is your best friend—like a roadmap but without the pesky traffic. If you hit a snag, check for common issues like loose connections. A small nudge can sometimes fix a big problem, like giving life advice to your cat! For the detailed steps, refer to the handy table below:

| Issue | Solution |

|---|---|

| Power not working | Check the fuse and connections. |

| Motor won’t start | Inspect the wiring and switch. |

| Overheating | Ensure proper ventilation. |

With a little patience and humor, you’ll have that lathe humming away in no time!

Safety Precautions When Wiring a Metal Lathe

Critical safety tips and best practices. How to avoid electrical hazards during installation.Wiring a metal lathe is exciting, but safety is key. Follow these tips to avoid dangers:

- Always turn off power before working.

- Use insulated tools to prevent shocks.

- Wear safety goggles for eye protection.

- Keep your workspace dry and tidy.

- Double-check connections to avoid sparks.

These simple actions can keep you safe while you bring creativity to life! Remember, safety first helps you enjoy your hobbies without worries.

What are the safety tips during installation?

Critical tips include turning off power, using insulated tools, and keeping the workspace clean. These precautions make sure you stay safe while working on your lathe.

Resources for Further Learning

Recommended books and online courses. Forums and communities for hobbyist lathes.Learning more about hobbyist metal lathes can be fun and rewarding! Consider picking up some recommended books that break everything down. For online courses, platforms like Udemy offer great options. Connecting with others is key, too. Check out forums where seasoned hobbyists share tips and tricks. You never know, someone might help wire your lathe faster than you can say “lathe guru!”

| Resource Type | Examples |

|---|---|

| Books | “Lathe Fundamentals” by John Smith |

| Online Courses | Lathe Basics on Udemy |

| Forums | Hobbyist Lathe Enthusiasts Forum |

Frequently Asked Questions

Common queries about metal lathe wiring. Expert answers to troubleshooting issues.Many people ask about metal lathe wiring. Here are some common questions:

What should I do if my lathe won’t start?

Check the power source first. Make sure everything is connected securely. If it still doesn’t work, look for a blown fuse. Replace any burned-out fuses.

How can I fix a short circuit?

Locate the wires that are damaged or frayed. Replace them immediately. Always unplug your machine before working on it to stay safe.

Where can I find wiring diagrams?

Your user manual is a great first step. You can also find helpful wiring diagrams online. Search specifically for hobbyist metal lathe wiring diagram.

With these tips, you can troubleshoot your lathe quickly and easily!

Conclusion

In summary, a hobbyist metal lathe wiring diagram helps you understand how to connect wires safely. You can use this knowledge to set up your lathe correctly. Make sure to follow safety guidelines while working with electricity. For more details, consider exploring online resources or forums. Engaging with other hobbyists can enhance your skills and knowledge. Happy machining!FAQs

What Are The Essential Components Needed For Wiring A Hobbyist Metal Lathe?To wire a hobbyist metal lathe, you need a few important parts. First, get a power supply to provide electricity. Then, use motor wires to connect the motor to the power supply. You also need switches to turn the lathe on and off easily. Finally, make sure to use safety equipment, like fuses, to prevent problems.

How Do You Correctly Wire The Motor Of A Hobbyist Metal Lathe To Ensure Safe Operation?To safely wire the motor of your hobbyist metal lathe, first, make sure the power is off. Then, connect the wires from the motor to the power supply. Match the colors: usually, black is for power, and white is for neutral. Use electrical tape to cover the connections. Finally, check everything is tight before turning the power back on.

What Electrical Diagram Conventions Should I Follow When Creating A Wiring Diagram For A Metal Lathe?When you create a wiring diagram for a metal lathe, use clear symbols for each part. We should label all wires and connections clearly. It’s important to use straight lines for wires to show how they connect. Always keep the diagram neat so you can easily read it later. Finally, include a key to explain any special symbols you use.

How Can I Troubleshoot Common Wiring Issues In A Hobbyist Metal Lathe Setup?To troubleshoot wiring issues in your metal lathe, first, check the power cord. Make sure it’s plugged in tightly and not damaged. Next, look for any loose wires; you can gently wiggle them to see if they feel secure. If your lathe isn’t turning on, try a different outlet. Finally, if it still doesn’t work, ask an adult to help you check the wiring connections.

Are There Specific Safety Precautions To Consider When Wiring A Metal Lathe For Hobby Use?Yes, there are important safety steps to follow when you wire a metal lathe. First, always unplug the machine when you’re working on it. Make sure your hands are dry and wear safety goggles to protect your eyes. Keep your workspace clean to avoid accidents. Lastly, double-check all connections to prevent sparks or short circuits.