Have you ever wondered how to create perfect holes in metal? A metal lathe is an amazing tool that can help you do just that. Using a metal lathe is like magic, but it’s really just skill and technique.

Boring holes might sound easy, but it takes practice. You may ask, “Where do I even start?” The good news is you don’t need to be a master machinist to learn this skill.

Think of a metal lathe as a giant pencil sharpener for metal. With the right steps, you can make precise holes quickly. Did you know that even small mistakes can lead to big problems later on? That’s why learning how to bore holes properly is so important.

This article will guide you through the steps to use a metal lathe safely and effectively. Are you ready to discover the secrets of boring holes? Let’s dive in and get started!

How To Bore Holes With A Metal Lathe: A Comprehensive Guide

How to Bore Holes with a Metal Lathe

Boring holes with a metal lathe can be fun and rewarding. First, ensure you have the right tools, like a boring bar and cutting tool. Set the lathe speed correctly for your material. Remember, using sharp tools makes a big difference! As you work, steady hands and patience are key. Have you ever wondered how precision machinery works? Boring holes is an essential skill in metalworking, unlocking countless creative projects. Start experimenting and see what you can create!Safety Precautions When Operating a Metal Lathe

Importance of personal protective equipment (PPE). Common safety practices to follow while working.Using a metal lathe is fun, but safety comes first! Always wear personal protective equipment (PPE). This includes safety goggles, gloves, and a snug-fitting apron. No one wants a flying piece of metal to ruin their day!

Keep your workspace tidy. A clean area reduces accidents. Familiarize yourself with the lathe’s controls and don’t wear loose clothes. They are like magnets for machinery. Also, remember to keep your hair tied back, unless you want a new hairstyle courtesy of the lathe!

| Safety Gear | Purpose |

|---|---|

| Safety Goggles | Protect your eyes from debris. |

| Gloves | Prevent cuts and scrapes. |

| Apron | Protect your clothes and body. |

Remember, your safety is top priority! Enjoy drilling those holes, but keep your fingers safe!

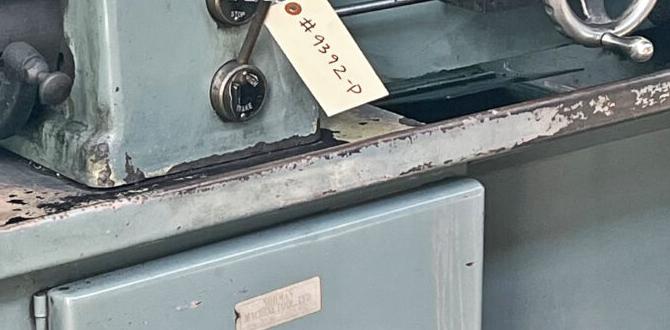

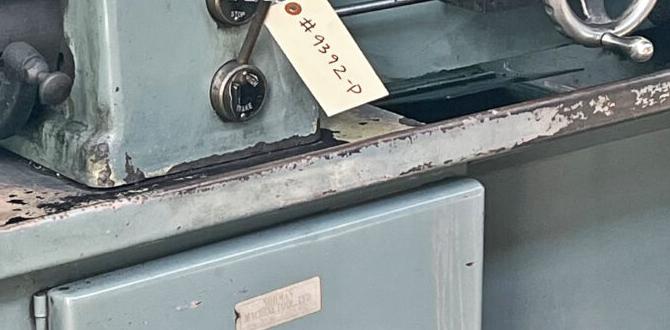

Preparing Your Metal Lathe for Boring

Steps to ensure the lathe is properly set up. Importance of selecting the right tools and accessories.Before you start boring holes, it’s crucial to get your metal lathe ready. First, check that the lathe is clean and free of dust. A dirty lathe might give you more problems than a cat in water! Next, be sure to use the right accessories. The wrong tool can turn your project into a messy art piece. Also, double-check the setup and adjust the speed settings carefully. Here’s a quick checklist to help you out:

| Step | Action |

|---|---|

| 1 | Clean the lathe |

| 2 | Select the right tools |

| 3 | Adjust speed settings |

| 4 | Inspect alignment |

Following these steps can save you time and heartache. Remember, a well-prepared lathe is like a happy chef—ready to cook up something great!

Choosing the Right Boring Tool

Different types of boring tools available. Factors to consider when selecting a boring tool.Choosing the perfect boring tool can feel like picking a favorite flavor of ice cream. There are several types available, each with its own special job. Common ones include drill bits, boring bars, and tapered reamers. When picking a tool, consider things like the size of the hole, material type, and depth needed. Don’t forget: the right tool makes the job smoother, like choosing chocolate instead of broccoli!

| Tool Type | Best For |

|---|---|

| Drill Bits | Small holes |

| Boring Bars | Large, precise holes |

| Tapered Reamers | Widening holes |

Setting Up the Workpiece

Techniques for securely fastening the workpiece. Ensuring proper alignment and centering.Before you start boring holes, it’s important to set up your workpiece correctly. First, fasten it securely. Use clamps or a vise to hold it tight. This way, it won’t move while you work. Next, you need to align and center your workpiece. An easy trick is to measure from the ends to the center. Make sure everything is straight. This helps in making clean and accurate holes!

How can I ensure my workpiece is properly aligned?

To ensure proper alignment, make sure to measure from each end equally. Use a ruler or caliper to find the center point. Adjust your workpiece until it sits perfectly. This step is key for achieving the best results!

Techniques for Boring Holes

Stepbystep guide on the boring process. Tips for achieving accurate hole dimensions.Boring holes in metal can sound tricky, but it’s actually quite fun! Start by securely holding your workpiece in the lathe. Next, choose the right boring tool. Move the tool slowly to avoid mistakes. Measure your hole, and if it’s not perfect, don’t worry! You can use a caliper to check sizes. Remember, practice makes perfect—well, almost! Always wear safety gear because while we love metal, we don’t want to be in any *sticky* situations!

| Step | Action |

|---|---|

| 1 | Secure workpiece |

| 2 | Select boring tool |

| 3 | Move tool slowly |

| 4 | Measure the hole |

| 5 | Check size with caliper |

Common Issues and Troubleshooting Tips

Identifying and fixing common problems during boring. Preventative measures to avoid issues in the future.While using a metal lathe for boring, problems can happen. You might face issues like vibrations or an uneven hole. Fix these by checking your tool’s sharpness or the machine’s setup. Prevention is key; always keep tools clean and double-check settings before starting.

- Use sharp tools to avoid tearing the metal.

- Check the speed; too fast can cause damage.

- Ensure the workpiece is secure to stop wobbles.

What are common issues when boring holes?

Common issues include tool wear, improper alignment, and vibrations. These can lead to poor hole quality and affect machining precision.

How can I prevent issues in boring?

- Maintain your tools regularly.

- Always check and adjust machine settings.

- Secure your workpiece firmly.

Caring for Your Metal Lathe After Boring

Cleaning and maintenance practices for longevity. Importance of regular inspections and part replacements.Keeping your metal lathe clean is vital for its health. Regular cleaning helps remove metal shavings and dust. This prevents rust and ensures smooth operations. Check your parts every now and then. Look for any wear or damage, and replace parts as needed. Regular upkeep can extend the life of your lathe. Think of it as taking care of a pet—it needs attention to stay happy and functional.

How often should I inspect my metal lathe?

Inspect your lathe every month. This helps catch problems early and ensures it works properly. It is like checking your bike tires before a ride.

Cleaning and Maintenance Tips:

- Use a soft brush to clear dust and debris.

- Wipe down surfaces with a damp cloth.

- Check for loose screws and tighten them.

Conclusion

In conclusion, boring holes with a metal lathe is a useful skill. You can create precise holes using the right tools and techniques. Remember to set the right speed and feed rate for your material. Practice makes perfect, so try it out! For more tips or tricks, consider reading guides or watching videos online. You’ve got this!FAQs

Here Are Five Related Questions On The Topic Of Boring Holes With A Metal Lathe:Sure! A metal lathe is a machine that helps us make holes in metal. First, we secure the metal piece tightly. Then, we use a special tool that spins around to cut into the metal. As it turns, it creates a smooth hole. Remember to always wear safety gear while working!

Sure! Just ask your question, and I’ll give you a clear and simple answer.

What Are The Different Types Of Boring Tools That Can Be Used On A Metal Lathe?On a metal lathe, you can use several types of boring tools. The most common are boring bars, which help make holes bigger. You can also use undercutting tools, which cut into the sides of a hole. Another type is the boring head, which holds different cutting bits for precision work. Each tool has its own special job, helping you create different shapes in metal.

How Do You Determine The Appropriate Speed And Feed Rate When Boring With A Lathe?To find the right speed and feed rate when boring with a lathe, you can start by checking the material you’re using. Different materials need different speeds. You can also use a simple formula, where speed is based on the tool and material. Finally, remember to listen and feel the machine. If it sounds or feels wrong, adjust the speed or feed.

What Safety Precautions Should Be Taken When Using A Metal Lathe For Boring Operations?When using a metal lathe for boring, we must be very careful. Always wear safety goggles to protect your eyes. Keep your hands away from the spinning parts to avoid getting hurt. Make sure long hair is tied back and loose clothes are tucked in. Finally, always double-check that everything is secure before you start working.

How Can You Ensure The Accuracy And Precision Of The Hole Diameter While Boring On A Lathe?To make sure the hole is the right size when boring on a lathe, you should measure your tools carefully. Always check the size of the hole as you work. Use a ruler or caliper for precise measurements. Keep your lathe clean and well-maintained for the best results. Take your time and go slowly to avoid mistakes.

What Are The Common Mistakes To Avoid When Boring Holes With A Metal Lathe?When using a metal lathe to make holes, we should avoid a few common mistakes. First, make sure the tool is sharp. A dull tool can cause bad cuts. Second, don’t go too fast. If you spin too quickly, it can break the tool or the piece you are working on. Lastly, always check your measurements before you start. It’s important to be accurate to avoid mistakes.