Choosing the right metal lathe pulley can feel tricky. Have you ever wondered why some projects turn out better than others? Sometimes, it’s all about the tools. Just like picking the best ingredients for a recipe, selecting the right pulley can make a big difference.

Imagine you’re in a workshop, ready to create something amazing. You grab your metal lathe. But wait! Do you know how to choose the best pulley for it? Each pulley has unique features. Using the wrong one might spoil your hard work. This article will help you find the perfect match.

Did you know that the right pulley can also save you time and effort? It helps the lathe run smoothly and make your tasks easier. Let’s dive in and discover how to choose a metal lathe pulley that works for you!

How To Choose A Metal Lathe Pulley: Essential Tips And Guidance

How to Choose Metal Lathe Pulley

Choosing the right metal lathe pulley can feel tricky. Start by considering the size and weight you need for your project. Different materials impact performance, too. Want flexibility? Look at adjustable pulley systems. Did you know the right pulley can enhance your lathe’s efficiency? Understanding these factors helps you make a smart choice. Dive into specifics like gear ratios and noise levels. Picking wisely means better results in your metalwork adventures!Understanding Metal Lathe Pulleys

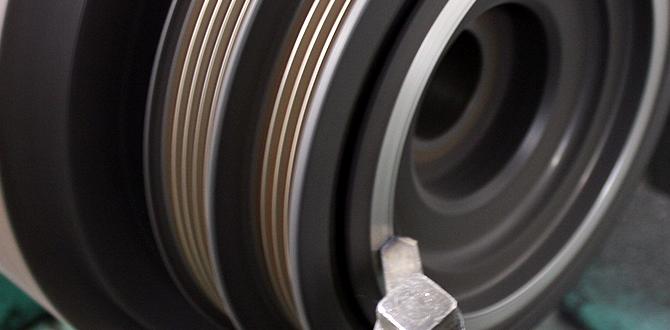

Definition and function of metal lathe pulleys. Types of metal lathe pulleys available in the market.Metal lathe pulleys are essential parts that help machines run smoothly. They connect different components and transfer power. This makes it easier to turn materials into finished products. There are various types of metal lathe pulleys, each serving a unique purpose. Popular types include:

- Flat Pulleys

- V-Belt Pulleys

- Idler Pulleys

Choosing the right one can improve your machine’s performance significantly.

What are the main functions of metal lathe pulleys?

The main functions of metal lathe pulleys include power transfer, speed regulation, and tension adjustment. They ensure the machine operates efficiently.

Factors to Consider When Choosing a Metal Lathe Pulley

Size and compatibility with your lathe model. Material quality and durability considerations.Picking the right metal lathe pulley isn’t just a walk in the park. First, size and compatibility are key. Make sure it fits your lathe model like a snug glove. If it’s too big or small, you might end up with a fancy paperweight! Next up, consider the material quality. Look for durable materials that can take a beating. After all, you don’t want to replace it every week! Here’s a handy table to assist you:

| Factor | Tips |

|---|---|

| Size | Match it with your lathe model |

| Material | Choose sturdy metals |

Remember, choosing a metal lathe pulley can make or break your project. Pick wisely and let the magic happen!

Benefits of Upgrading Your Metal Lathe Pulley

Increased efficiency and performance. Enhanced precision in machining.Upgrading your metal lathe pulley can boost your machine’s game! It helps your lathe work better and faster, meaning you finish tasks in no time. With a new pulley, you’ll notice increased efficiency. Plus, you’ll create parts with more precision. Who doesn’t want to make perfectly round doughnuts out of metal? Think of it as swapping out a rusty old bike tire for a speedy new one; suddenly, you’re the fastest one on the block!

| Benefit | Description |

|---|---|

| Efficiency | Faster production, less waiting! |

| Precision | Perfect cuts and shapes every time. |

Common Mistakes to Avoid

Overlooking weight and balance issues. Failing to consider power transmission requirements.Many people miss out on important details while selecting a metal lathe pulley. One big mistake is ignoring weight and balance issues. A heavy pulley can make your machine wobble, and nobody wants a seesaw lathe! Another error is not thinking about power transmission requirements. If your pulley can’t handle the power, it’s like trying to run with flip-flops on. Use the right pulley, avoid these common pitfalls, and keep your projects spinning smoothly!

| Mistake | Why Avoid? |

|---|---|

| Ignoring Weight & Balance | Can cause wobbling and uneven cuts. |

| Neglecting Power Needs | Leads to pulley failure or inefficient performance. |

Maintenance Tips for Longevity

Regular inspection and cleaning practices. Importance of lubrication and care for pulleys.To keep your metal lathe pulley in great shape, regular care is important. Check it for dirt and damage. Cleaning helps it work better and last longer. Lubrication is key too. It reduces friction and wear. Use the right oil to keep parts moving smoothly.

- Inspect pulleys for dirt and wear weekly.

- Clean with a soft cloth to avoid scratches.

- Lubricate every month with quality oil.

By keeping up with these tasks, you can enjoy a longer life for your equipment.

How often should I clean and lubricate my metal lathe pulley?

You should clean your metal lathe pulley weekly and lubricate it every month for the best results. Regular maintenance keeps your pulley working well.

Frequently Asked Questions

Common queries regarding metal lathe pulleys. Troubleshooting issues related to lathe pulley performance.Many people wonder about metal lathe pulleys. Here are some common questions and answers to help you understand better.

What are the signs of pulley problems?

Look for strange noises, vibrations, or slips in the belt. These can mean something is wrong. Regular checks can prevent major issues.

How can I improve pulley performance?

- Keep it clean. Dust or grease can affect performance.

- Check for wear. Replace any damaged parts.

- Ensure proper alignment. Misalignment can lead to failures.

Following these tips can help keep your lathe running smoothly. Don’t hesitate to ask for help if you’re unsure.

Conclusion

Choosing a metal lathe pulley requires careful consideration. First, know your lathe’s specifications. Next, think about the material and size that suits your projects. Check for durability and compatibility with your machine. Remember, a good pulley enhances performance. Take time to research and compare options. For more information, explore guides and reviews online to make the best choice.FAQs

Here Are Five Related Questions On The Topic Of Choosing A Metal Lathe Pulley:Sure! When choosing a metal lathe pulley, think about how heavy it needs to be. Heavier pulleys are often more steady. Also, check what size the pulley should be. It has to fit your lathe perfectly. Lastly, look for strong materials so it lasts a long time.

Sure! Please give me the question you’d like me to answer.

What Factors Should I Consider When Selecting The Right Pulley Size For My Metal Lathe?When choosing a pulley size for your metal lathe, think about a few things. First, consider how fast you want the lathe to spin. Bigger pulleys make it go faster, while smaller ones make it slower. Also, check the power of your motor to match the pulley size. Lastly, make sure it fits well with other parts, so everything works smoothly.

How Do The Materials Used In Lathe Pulleys Affect Their Performance And Durability?The materials in lathe pulleys make a big difference in how well they work. For example, strong metals like steel last longer and can handle heavy loads. If we use lighter materials, the pulleys might not break, but they may wear out faster. Good materials help the machine run smoothly and last a long time.

What Is The Importance Of Pulley Ratio In Relation To Spindle Speed In A Metal Lathe?The pulley ratio in a metal lathe helps control how fast the spindle spins. When you change the pulley ratio, you can make the spindle go faster or slower. This is important because different tasks need different speeds. For example, cutting metal often needs a slower speed for better control. So, the pulley ratio helps us do our work just right!

How Can I Determine The Correct Bore Size And Keyway Dimensions For My Lathe Pulley?To find the right bore size for your lathe pulley, you need to measure the shaft’s diameter. Use a ruler or caliper to get this measurement. For the keyway, measure the width and depth needed to fit your key. You can also look at the old pulley for size clues. Then, write down your measurements and take them to a hardware store to get the right parts.

Are There Specific Brands Or Manufacturers Known For Producing High-Quality Metal Lathe Pulleys?Yes, there are some well-known brands that make good metal lathe pulleys. Companies like Grizzly, Jet, and Shop Fox are popular. They create strong and reliable parts. You can usually trust their products to work well. If you need a metal lathe pulley, you might want to check these brands.