Have you ever tried to carve soap with a dull knife? It’s tough, right? Think of your workshop and the tools in it. One important tool is the end mill. Did you know that you can sharpen an end mill at home? It’s true. Many people think you need special skills. You don’t. With a bit of practice, you can do it too.

Let me take you to the past. People in ancient times sharpened stones to make them useful. Today, sharpening an end mill is much like that. You don’t need magic, just patience and simple steps. Anyone who loves to build things wants sharp tools. When you learn how to sharpen an end mill, you make sure your tools stay helpful.

Why should you care? Because a sharp end mill makes work easier and faster. Your projects turn out nice and smooth. This skill can save you time and money. You might even amaze your friends with this handy trick!

Are you curious? Let’s explore the process of making your end mill sharp and shiny. This journey might surprise you!

How To Sharpen End Mill: A Comprehensive Guide Sharpening End Mills Is A Crucial Skill For Any Machinist Or Hobbyist Working With Metal Cutting Tools. Ensuring Your End Mills Are Sharpened Correctly Extends Their Life, Improves Work Efficiency, And Guarantees High-Quality Results. Here’S A Step-By-Step Guide On How To Sharpen An End Mill. Understanding End Mills End Mills Are Cutting Tools Used In Milling Applications. They Come In A Variety Of Shapes And Sizes, Each Designed For Specific Tasks Such As Side Milling, End Milling, Or Slotting. Over Time, The Cutting Edges Will Dull, Impacting The Precision And Efficiency Of Your Work. Tools Required For Sharpening Before You Begin The Sharpening Process, Gather The Necessary Tools: 1. **Bench Grinder Or Tool And Cutter Grinder**: A Bench Grinder Is Adequate For Basic Resharpening, While A Tool And Cutter Grinder Offers More Precision. 2. **Diamond Wheel**: This Is Used For Grinding The Carbide Tips. 3. **Collet Fixture**: To Hold The End Mill Securely While Sharpening. 4. **Dial Calipers**: These Ensure Precise Measurements During Sharpening. 5. **Safety Gear**: Safety Glasses And Gloves Are Essential To Protect Against Sharp Fragments And Metal Filings. Steps To Sharpen An End Mill 1. **Evaluate The Condition**: Inspect The End Mill To Determine How Much Material Needs To Be Removed. Look For Obvious Signs Of Wear And Dullness. 2. **Secure The End Mill**: Use The Collet Fixture To Hold The End Mill Securely In Place. Make Sure It Doesn’T Wobble During Sharpening. 3. **Set Up The Grinder**: Align The Diamond Wheel Such That It Makes Proper Contact With The End Mill’S Flutes. Adjust The Grinder’S Speed And Angle To Fit The Specific Requirements Of The End Mill You’Re Sharpening. 4. **Sharpen The Flutes**: Carefully Sharpen Each Flute By Angling The Grinder. Ensure You’Re Holding The End Mill At The Correct Angle To Maintain Its Original Geometry. Consistent Pressure Should Be Applied Throughout The Process. 5. **Check For Evenness**: After Sharpening, Use The Dial Calipers To Ensure Each Flute Is Of Equal Length And The Cutting Edges Are Even. 6. **Remove Burrs**: Use A Fine-Grit Wheel Or A File To Remove Any Burrs Or Rough Edges Left From Sharpening. 7. **Test The Sharpness**: After Sharpening, Test The End Mill On A Piece Of Scrap Material To Ensure It Performs Correctly. Look For Smooth And Clean Cuts. Maintenance Tips – **Regular Inspection**: Routinely Check Your End Mills For Dullness Or Damage To Schedule Sharpening Before Performance Issues Arise. – **Proper Storage**: Always Store End Mills In A Protective Holder To Prevent Accidental Damage. – **Lubrication During Use**: Apply Cutting Fluid During Milling To Reduce Heat Buildup And Prolong The Life Of The Tool. Conclusion Sharpening An End Mill Effectively Can Save Both Time And Money While Ensuring Precision In Your Work. By Following This Guide And Regularly Maintaining Your Tools, You Can Significantly Enhance Your Milling Operations And Achieve Superior Results.

How to Sharpen End Mill

Sharpening an end mill might sound tricky, but it’s simpler than you think. Imagine your favorite pencil getting dull. Would you stop writing? No way! You sharpen it. Just like that pencil, an end mill needs sharpening to work its magic again. Equip yourself with a grinder, and save money by reusing your mills. Isn’t it cool to give tools a second life? It’s like being a tool superhero, fighting dullness!Understanding End Mills and Their Importance

Definition and types of end mills. Role of end mills in machining processes.End mills are special cutting tools with a flat end. They make cool shapes and holes in metal and wood. Think of them like pencils for machines. Carbide end mills, a popular type, are strong and sharp. There are also different types like ball-nose and corner-radius. End mills are important in machining processes. They help create clean edges and precise parts in different tools and machines. When you sharpen them, they stay useful for a long time!

Why is sharpening an end mill important?

Sharpening an end mill keeps it efficient. Sharp tools cut better, reduce waste, and save costs. Regular sharpening extends tool life, maintaining high-quality results in machining. Also, it prevents machine damage and ensures smooth operations.Signs That Your End Mill Needs Sharpening

Indicators of wear and tear. Impact of dull end mills on working efficiency.Ever wondered if your end mill needs sharpening? Check for signs of wear and tear. If you see rough edges or chips, it’s time! A dull end mill works slower and less precise. This costs time and energy. Keep an eye out!

What happens if I use a dull end mill?

A dull end mill affects work quality and increases operating costs. The cuts won’t be smooth, and bits can break. You use more energy and resources. It’s like trying to cut food with a blunt knife—hard and messy!

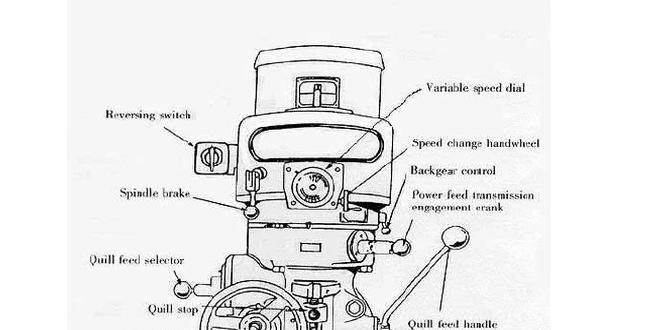

Tools and Equipment Needed for Sharpening End Mills

Essential sharpening tools. Optional advanced sharpening equipment.Sharpening end mills needs the right tools. Here are essential tools you need:

- Bench Grinder: It shapes and sharpens the mills.

- Grinding Wheel: Different types for different materials.

- Safety Gear: Gloves and goggles protect you.

Optional tools make things easier:

- Air Compressor: Keeps tools cool.

- Diamond Wheel Dresser: Keeps the grinding wheel smooth.

Why is a bench grinder essential for sharpening?

The bench grinder helps to make precise edges on end mills. It ensures the tool cuts cleanly. Using it requires caution. Always wear safety gear.

Step-by-Step Guide to Sharpening End Mills

Preparation and safety measures. Step 1: Inspecting the end mill for damage. Step 2: Setting up the sharpening machine. Step 3: Aligning the end mill. Step 4: Grinding the primary angle. Step 5: Refining secondary angles and reliefs. Step 6: Final inspection and adjustments.Before diving into sharpening end mills, safety is key. Get your safety glasses on and check for any loose clothing. Start by

inspectingthe end mill for chips or cracks. If it looks like it’s seen a better day, replace it. Got the right end mill? Great, let’s set up the sharpening machine. Make sure everything is secure, no wobbly bits here! Next up, align the end mill carefully; precision is the goal here.

Once you’re set, it’s time to grind the primary angle. This requires a steady hand and patience. Grind too fast, and you’ll end up with a funky-shaped tool. After, refine the secondary angles and reliefs; it’s like giving the tool a nice haircut. Finally, do a thorough inspection. Make small adjustments if needed. Better safe than sorry, right? Your end mill is now sharp and ready to go!

| Step | Action |

|---|---|

| Preparation | Safety gear, inspect for damage |

| Step 1 | Inspect end mill |

| Step 2 | Set up sharpening machine |

| Step 3 | Align end mill |

| Step 4 | Grind primary angle |

| Step 5 | Refine angles and reliefs |

| Step 6 | Final inspection and adjustments |

Common Mistakes to Avoid During Sharpening

Overheating the end mill. Incorrect angle adjustments. Ignoring chip removal and clearance issues.Sharpening an end mill is like giving it a refreshing haircut. But hey, let’s skip the “Oops!” moments. To start, watch out for overheating; they prefer to stay cool and calm. Angle adjustments must be precise. Did someone say 90 degrees? Nope, that’s for right turns! Don’t forget about chip removal and clearance issues. Ignoring them is like leaving crumbs all over and wondering why ants are visiting. Keep it tidy!

| Common Mistakes | Why Avoid? |

|---|---|

| Overheating | Shortens tool life |

| Incorrect Angles | Poor cutting performance |

| Ignoring Chip Removal | Can cause blockages |

Maintenance Tips for Prolonging the Life of Sharpened End Mills

Proper cleaning and storage. Recommended usage practices. Regular inspection schedules.How do you keep sharpened end mills in good condition?

Proper care extends the life of sharpened end mills. Follow these tips for best results.Clean the end mills after each use. Use a brush to remove chips and debris. Store them in a dry place to avoid rust. Use a protective cover to avoid damage. Always handle with care.

- Operate within recommended speed and feed rates.

- Avoid cutting materials harder than the tool’s capacity.

- Keep a balanced load on the tool.

Inspect end mills regularly. Look for signs of wear and tear. Replace end mills when they show significant damage or dullness. Regular checks prevent unexpected breaks and ensure the best performance.

How often should I inspect end mills?

Inspect end mills after every 20 hours of use. This routine ensures timely detection of issues and helps maintain precision. Regular inspections guarantee longer tool life and a smooth operation in every project.

Alternative Options: When to Consider Professional Services or Replacement

Benefits of professional sharpening services. Cost considerations for replacement versus sharpening.Sometimes, sharpening tools like end mills can be tricky. That’s when you might want to call in the pros. Professional sharpening services can give your tools a new lease on life, making them work like magic. Plus, they know their stuff, which saves you time and headaches. Now, let’s talk cost. Sometimes, replacing that old end mill seems cheaper, but in the long run, sharpening can save you pennies!

| Option | Cost | Duration |

|---|---|---|

| Professional Sharpening | $$ | Quick Turnaround |

| Replacement | $$$$ | Hours to Days |

So, before tossing it aside, weigh your options! Remember, a new tool can take time to settle in, but a sharpened one will return to work faster than you can say, “Where’s my coffee?”

FAQs on End Mill Sharpening

How often should end mills be sharpened?. Can all end mills be sharpened?. What are the costs involved in sharpening end mills?.End mills are like little superheroes for machines, but even superheroes need a break! You should sharpen end mills when you notice they’re not cutting as well. This could be every few weeks or months, depending on use. Not all end mills can be sharpened. High-speed steel ones are great candidates, while some coated ones might not be. Usually, sharpening costs range from $10 to $40 per tool. Remember, a sharp tool is a happy tool!

| Question | Answer |

|---|---|

| How often should they be sharpened? | When they start cutting poorly. |

| Can all end mills be sharpened? | No, some coated ones can’t. |

| What are the costs? | Typically $10 to $40 per tool. |

Conclusion

Sharpening an end mill involves using a grinder to restore its edges. It’s important to maintain a steady hand and use proper tools. Remember to check the angles and remove even amounts of material. Practicing these steps helps your tools last longer. For more guidance, consider reading detailed tutorials or watching online videos on sharpening techniques.FAQs

Sure! Here Are Five Related Questions On The Topic Of How To Sharpen End Mills:To sharpen end mills, you can use a special grinding machine. First, make sure the end mill is clean. Then, set the machine to the right angle for the type of end mill you have. Slowly move the end mill against the grinding wheel until it’s sharp. Always wear safety goggles to protect your eyes!

Sure! Please provide me with the question you want answered.

What Are The Key Steps Involved In Sharpening An End Mill Using A Tool And Cutter Grinder?To sharpen an end mill using a tool and cutter grinder, first, you need to set the end mill in the machine. Next, make sure the grinding wheel is lined up correctly. Then, you carefully grind the cutting edges of the end mill. After sharpening, check if it looks good and feels sharp. Finally, clean the end mill and put it away safely.

How Can I Determine The Correct Relief Angles When Sharpening An End Mill?To find the right relief angles for sharpening an end mill, start by looking at the original angle. You can use a protractor or angle gauge to measure it. If you don’t have those tools, just follow the shape of the end mill closely. You can also check a guide or instructions for your specific end mill type. Finally, practice makes perfect, so keep trying until it feels right!

What Tools And Equipment Are Necessary For Sharpening End Mills Effectively?To sharpen end mills, you need a few important tools. First, you’ll want a grinding machine. This helps shape the end mills correctly. Next, use a diamond wheel for a smooth finish. Finally, a measuring tool is handy to check the angles. With these tools, you can sharpen them well!

How Does The Material Of The End Mill Affect The Sharpening Process And Techniques Used?The material of the end mill changes how we sharpen it. If it’s made of steel, we can use a simpler sharpening tool. But if it’s made of harder materials like carbide, we need special tools. These tools are stronger and can handle the tough materials. Choosing the right technique helps us keep the end mill working well.

Can End Mills Be Sharpened By Hand, And If So, What Are The Best Practices For Doing So?Yes, you can sharpen end mills by hand. First, you need a good sharpening tool, like a bench grinder. Make sure to hold the end mill steady and grind at the right angle. You can use a marker to check if you’re sharpening evenly. Always wear safety glasses to protect your eyes!