Do you ever wonder how sharp tools make our work easier? Milling cutters are among the most important tools in machining. They help shape and cut materials with precision. But what happens when these cutters become dull? They struggle to do their job well, and that can lead to mistakes.

Imagine trying to slice through bread with a butter knife. It’s frustrating, right? The same goes for dull milling cutters. They need sharpening to perform their best. Fortunately, sharpening these tools isn’t as hard as it sounds.

In this article, we will explore how to sharpen milling cutters. You might be surprised at how simple and effective some methods can be. There are tips and tricks that can help you get your tools back in shape quickly. So, are you ready to discover the secrets of keeping your milling cutters sharp?

How To Sharpen Milling Cutters: Techniques And Tips

How to Sharpen Milling Cutters

Sharpening milling cutters is important for smooth, precise cuts. First, choose the right sharpening method—either manual or using a machine. Make sure to inspect the cutter for damage. Use a diamond wheel for best results. Did you know that proper sharpening can extend the life of your tools? Regular maintenance ensures high-quality work and saves money in the long run. Follow these tips to keep your milling cutters in top shape!Understanding Milling Cutters

Definition and types of milling cutters. Importance of sharp milling cutters in machining.Milling cutters are tools that help shape and cut materials. They come in many types, like flat end mills and ball end mills, each suited for different jobs. Think of them as different types of pizza cutters! Sharp milling cutters are super important because dull ones can ruin your work. They make clean cuts and save time. A sharp cutter is like a happy chef—ready to serve quality results!

| Type of Milling Cutter | Best For |

|---|---|

| Flat End Mill | Making flat surfaces |

| Ball End Mill | Creating rounded edges |

| High-Speed Steel (HSS) | General-purpose cutting |

| Carbide | Hard materials |

Remember, using sharp tools makes machining easier. Keep your cutters sharp, and they will cut through anything like a hot knife through butter!

Benefits of Sharpening Milling Cutters

Improved cutting performance and efficiency. Costeffectiveness and longevity of tools.Keeping milling cutters sharp has great perks! First, it boosts cutting performance, making your job smoother and faster. Imagine cutting through wood like a hot knife through butter! It also saves money. Sharpened tools last longer, reducing the need for replacements. Think of it as taking care of your favorite toy so it doesn’t break. Plus, who doesn’t love saving some cash?

| Benefit | Details |

|---|---|

| Improved Performance | Better cuts = faster work! |

| Cost-Effectiveness | Less need for new tools = happy wallet! |

| Longevity | Sharp tools outlast dull ones! |

Tools and Equipment Needed for Sharpening

Essential tools for sharpening milling cutters. Safety equipment to ensure safe sharpening practices.To sharpen milling cutters, you need some important tools. A grinding wheel is your main item. It shapes and sharpens the cutter’s edges. A dial gauge helps check the cutter’s angle. Don’t forget safety gear! Use goggles to protect your eyes. Ear protection is also useful. Here are some essential tools:

- Grinding wheel

- Dial gauge

- Bench grinder

- Safety goggles

- Ear protection

These tools make sharpening easier and safer!

What tools do I need for sharpening milling cutters?

You need a grinding wheel, a dial gauge, and safety gear like goggles. Safety is key when sharpening!

Step-by-Step Process for Sharpening Milling Cutters

Preparation of milling cutters for sharpening. Detailed sharpening procedures for different types of milling cutters.Before sharpening milling cutters, prepare them well. Clean off any dirt and old metal shavings. Inspect for damage and replace if needed. Next, let’s dive into sharpening! Different cutters need different techniques. For end mills, hold them at a 45-degree angle while sharpening. For face mills, keep them flat on the sharpener. Be careful! One wrong move could lead to an accidental haircut! Remember, practice makes perfect!

| Type of Cutter | Sharpening Angle | Tools Needed |

|---|---|---|

| End Mill | 45° | Bench Grinder |

| Face Mill | Flat | Sharpener |

Common Mistakes to Avoid When Sharpening

Oversharpening and its consequences. Ignoring tool geometries during the sharpening process.Sharpening milling cutters can be tricky. One big mistake is oversharpening. This can make your tool too weak and prone to breaks. Oops! Another error is ignoring the tool geometries. Each cutter has a unique shape that must be respected. If you don’t, your effort may go to waste. Remember, a happy cutter means happy cuts! Keep it sharp, but don’t go overboard!

| Mistake | Consequence |

|---|---|

| Oversharpening | Weakened tool, risk of breakage |

| Ignoring tool geometries | Poor performance, wasted time |

Maintenance Tips for Sharpened Milling Cutters

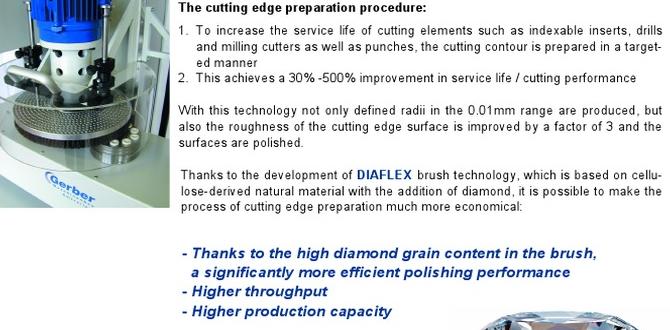

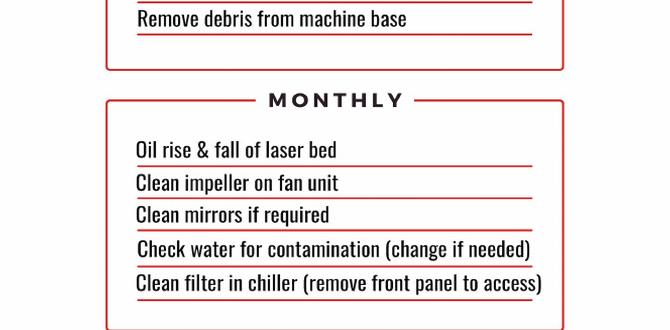

Best practices for maintaining cutting edge longevity. Proper storage techniques for sharpened milling cutters.To keep your sharpened milling cutters in great shape, follow these smart tips. Always clean cutters after use. This helps remove dust and grime. Store them in a dry place. Use protective caps or bags to avoid damage. Check for dullness regularly and sharpen as needed for better performance.

What are the best practices for maintaining cutting edge longevity?

Keep them clean. Store them properly. Check for wear often. Regular maintenance will help your cutters last longer.

Proper Storage Techniques

- Use a sharpener cover to prevent nicks.

- Store them in a toolbox or drawer.

- Avoid damp areas to prevent rust.

When to Replace Your Milling Cutters Instead of Sharpening

Signs that indicate a cutter should be replaced. Comparing the costeffectiveness of sharpening vs. replacement.Sometimes, it’s better to replace a milling cutter instead of sharpening it. Here are some signs to watch for:

- Visible damage or cracks

- Heavy wear on cutting edges

- Increased vibration during use

- Poor cutting performance

Replacing a cutter may seem costly, but it can save you money in the long run. Cutters that need frequent sharpening can lead to mistakes and wasted materials, which can add up.

When should you replace milling cutters instead of sharpening?

Replace them if they show heavy wear or damage, as it saves time and ensures quality work.

Conclusion

In summary, sharpening milling cutters keeps them efficient and effective. We learned to use grinding wheels, jigs, and hand tools for this task. It’s important to maintain the correct angle and use proper safety gear. Now that you know how to sharpen milling cutters, try it out! For more tips, check out resources on tool maintenance. Happy milling!FAQs

What Are The Different Methods For Sharpening Milling Cutters, And Which Is The Most Effective For Various Types Of Cutters?To sharpen milling cutters, we can use a few different methods. One way is using a grinding wheel, which spins fast and grinds the edges sharp. Another method is called honing, which smooths the cutting edges to make them better. For most types of cutters, using a grinding wheel is the best method because it works quickly and makes them really sharp. Always remember to be careful and wear safety gear when sharpening!

How Often Should Milling Cutters Be Sharpened To Maintain Optimal Performance And Tool Life?You should sharpen milling cutters when they start to feel dull or less effective. This usually happens after a few hours of use. If you notice your cuts are rough, it’s time to sharpen them. Keeping them sharp helps them last longer and work better. Regular checks are important for good performance!

What Tools And Equipment Are Necessary For Sharpening Milling Cutters Accurately?To sharpen milling cutters well, you need a few important tools. First, you should have a good grinding machine to smooth the edges. You also need a sharpening stone for fine touches. A tool holder helps keep everything steady while you work. Lastly, a measuring tool checks if the cutter is sharp enough.

Are There Specific Angles Or Geometries That Should Be Adhered To When Sharpening Different Types Of Milling Cutters?Yes, different milling cutters need special angles when you sharpen them. For example, end mills might need a 45-degree angle. Drill bits usually require a pointy angle for better drilling. Following the right angles helps the cutters work better and last longer. Always check the instructions for each type!

What Common Mistakes Should Be Avoided When Sharpening Milling Cutters To Prevent Damage Or Reduced Cutting Efficiency?When sharpening milling cutters, you should avoid a few common mistakes. First, don’t use the wrong angle; it can make the cutter less effective. Second, be careful not to overheat the metal. Overheating can cause damage that makes it break. Lastly, always clean the cutter properly after sharpening so that it works well.