Have you ever looked at a metal piece and thought, “I want to make this perfect”? If you work with a metal lathe, you can turn ideas into reality! A metal lathe helps you shape and smooth metal parts for many projects.

One important skill is learning how to square stock on a metal lathe. Why is squaring stock such a big deal? Well, a squared stock keeps your work neat and ensures everything fits just right. Imagine building something strong and stable but starting with a piece that isn’t even! It can be frustrating.

Here’s a fun fact: Even experienced machinists take the time to square their stock. They know it makes all the difference in the final product. In this article, you will discover tips and tricks to master the art of squaring stock. You’ll feel like a pro in no time!

How To Square Stock On Metal Lathe: A Step-By-Step Guide

How to Square Stock on Metal Lathe

Squaring stock on a metal lathe is an important skill for precision machining. First, secure your workpiece in the lathe chuck. Then, use a cutter to make the first edge square. Next, rotate the stock and repeat on the adjacent edge. This technique helps ensure accuracy in your projects. Did you know that properly squared stock can save time and enhance the quality of your work? Mastering this skill opens doors to more complex machining tasks!Understanding the Basics of Squaring Stock

Definition of squaring in metalworking. Importance of squaring stock before machining.Squaring stock in metalworking means making the edges and faces straight and at right angles. Imagine trying to build a house on a wobbly foundation! You wouldn’t get very far. Squaring stock is super important before machining because it ensures each cut is precise. This leads to better-fitting parts that actually work together. Otherwise, you might end up with a puzzle piece that just won’t fit! Square and straight mean success!

| Benefits of Squaring Stock |

|---|

| Allows for accurate cuts |

| Improves part fit |

| Reduces waste |

| Enhances safety |

Preparing the Workpiece

Steps to measure and mark the stock. Best practices for securing the stock in the lathe.Start by measuring your stock carefully. Use a caliper to check both length and width. Mark where you’ll cut. Keep the marks visible! Next, it’s essential to secure your workpiece in the lathe. You don’t want it wobbling like a jelly on a plate. Tighten the clamps evenly to prevent any drama. Using a center punch helps seat the stock perfectly. Lastly, double-check your setup before hitting the start button. Remember, safety first, then fun!

| Step | Action |

|---|---|

| 1 | Measure Length and Width |

| 2 | Mark Cutting Points |

| 3 | Secure the Workpiece |

| 4 | Use a Center Punch |

| 5 | Double-Check Setup |

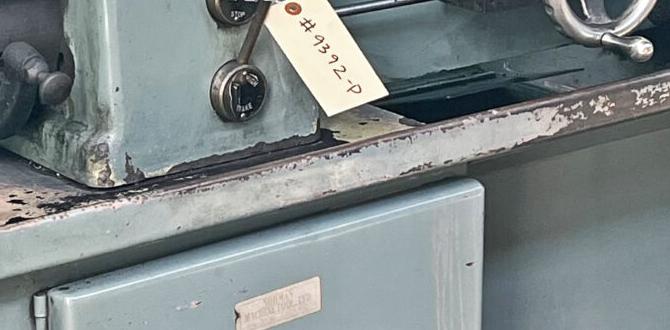

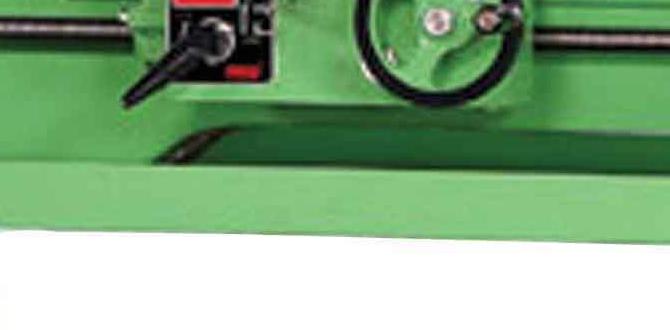

Setting Up the Metal Lathe

How to set the lathe for squaring operations. Adjustments and calibrations needed for accuracy.Before you start squaring stock on your metal lathe, a few setups are necessary. First, secure your workpiece using the proper chuck. Adjust your tailstock for stability. Calibrate the tool rest for correct height. This helps keep everything in line, or else your square might turn into a rectangle—yikes! Remember to check the alignment of the lathe bed, as that affects accuracy. Here’s a quick checklist to follow:

| Setup Item | Action |

|---|---|

| Workpiece | Secure in chuck |

| Tailstock | Adjust for stability |

| Tool Rest | Calibrate for height |

| Lathe Bed | Check alignment |

With these adjustments, you’re on the right track. Just remember, a square shape is great, but no one likes a wonky one!

The Squaring Process

Stepbystep guide to squaring stock on the lathe. Tips for maintaining precision during the process.Start by carefully measuring your stock. Precision is key. Place the piece on the lathe and secure it tightly. This helps prevent movement during cutting. Next, use a sharp cutting tool to square one face. Rotate the stock to square the opposite face. Repeat this for the other two sides. Always check your work. Use a caliper for accuracy. Adjust as needed. With practice, you will get better at squaring stock.

How can I maintain precision when squaring stock?

To keep things precise, follow these tips:

- Check measurements often.

- Use sharp tools to avoid mistakes.

- Keep the lathe clean and well-oiled.

- Practice steady hands while cutting.

Finishing Techniques

Methods for achieving a smooth finish after squaring. Importance of tooling and feed rates in finishing.To achieve a smooth finish after squaring, use various finishing techniques. Proper tooling makes a big difference in the quality of the surface. Feed rates also matter; a slower feed rate can lead to a better finish. Here are some key methods:

- Use fine cutting tools for a smoother surface.

- Adjust the feed rate to avoid rough spots.

- Use polishing compounds or sandpaper for final touches.

Always remember, a clean finish shows your work quality!

What tools help achieve a smooth finish?

Sharp cutting tools and polishing pads are essential for a smooth finish.

Application of Squared Stock in Projects

Examples of projects that require squared stock. Benefits of using squared stock in machining and assembly.Many projects need squared stock. For example, furniture making requires strong, flat pieces. Machine parts also use squared stock for better fit. This stock offers many benefits:

- Improved accuracy in measurements.

- Better assembly with other pieces.

- Stronger and more stable structures.

Using squared stock can make your projects faster and easier. It helps avoid mistakes. This way, you can be proud of your work!

What projects use squared stock?

Examples include building cabinets, creating metal frames, and assembling machinery. These projects benefit greatly from squared stock.

Conclusion

In conclusion, squaring stock on a metal lathe ensures precise cuts and accurate parts. Start by securing the material firmly to avoid movement. Use proper tools for the best results. Practice this skill to improve your techniques. For more tips, we encourage you to read guides or watch videos that demonstrate the process. Happy lathing!FAQs

What Are The Necessary Tools And Setup Required To Square Stock On A Metal Lathe?To square stock on a metal lathe, you need a few tools. First, get a metal lathe. This machine helps shape the metal. You also need a cutting tool to shave off the edges. A ruler or caliper can help you measure and check if it’s square. Finally, make sure the lathe is set up correctly and the stock is secure.

How Do You Ensure Accurate Measurements When Squaring Stock On A Lathe?To make sure your measurements are accurate when squaring stock on a lathe, start by checking your tools. Measure the stock carefully with a ruler or caliper. We can use a square tool to help us make straight lines. Always double-check your measurements before cutting. This way, your stock will be nice and even.

What Techniques Can Be Used To Achieve A Flat Surface While Squaring Stock On A Metal Lathe?To make a flat surface on a metal lathe, you can use a few simple steps. First, ensure your stock is steady and well-supported. Next, use the cutting tool and move it slowly across the surface. You can also adjust the tool’s height to make sure it cuts evenly. Lastly, keep checking with a straight edge to see if it’s flat.

How Do You Handle Stock Materials Of Varying Sizes And Shapes During The Squaring Process?When we have materials that are different sizes and shapes, we start by looking at each piece. We measure them to see how much needs to be cut off. Then, we use a tool, like a saw, to make straight cuts. This helps us make the pieces as square as possible. Finally, we check again to make sure they are all even and ready to use.

What Safety Precautions Should Be Taken When Squaring Stock On A Metal Lathe?When using a metal lathe to square stock, safety comes first! Always wear safety glasses to protect your eyes. Keep your fingers away from the moving parts. Make sure your hair and loose clothes are tied back. Finally, check that all tools and parts are secure before you start.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Necessary Tools And Setup Required To Square Stock On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To square stock on a metal lathe, you need a few tools. First, get a metal lathe. This machine helps shape the metal. You also need a cutting tool to shave off the edges. A ruler or caliper can help you measure and check if it’s square. Finally, make sure the lathe is set up correctly and the stock is secure.”}},{“@type”: “Question”,”name”: “How Do You Ensure Accurate Measurements When Squaring Stock On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make sure your measurements are accurate when squaring stock on a lathe, start by checking your tools. Measure the stock carefully with a ruler or caliper. We can use a square tool to help us make straight lines. Always double-check your measurements before cutting. This way, your stock will be nice and even.”}},{“@type”: “Question”,”name”: “What Techniques Can Be Used To Achieve A Flat Surface While Squaring Stock On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make a flat surface on a metal lathe, you can use a few simple steps. First, ensure your stock is steady and well-supported. Next, use the cutting tool and move it slowly across the surface. You can also adjust the tool’s height to make sure it cuts evenly. Lastly, keep checking with a straight edge to see if it’s flat.”}},{“@type”: “Question”,”name”: “How Do You Handle Stock Materials Of Varying Sizes And Shapes During The Squaring Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we have materials that are different sizes and shapes, we start by looking at each piece. We measure them to see how much needs to be cut off. Then, we use a tool, like a saw, to make straight cuts. This helps us make the pieces as square as possible. Finally, we check again to make sure they are all even and ready to use.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Squaring Stock On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe to square stock, safety comes first! Always wear safety glasses to protect your eyes. Keep your fingers away from the moving parts. Make sure your hair and loose clothes are tied back. Finally, check that all tools and parts are secure before you start.”}}]}