Have you ever watched a magic show? You see a hat, then a rabbit appears. Threading on a metal lathe seems like magic, too! You start with a plain metal rod, and suddenly, threads appear. How do you think that happens?

Imagine you twist the knob of a water bottle. Those grooves help the cap fit snugly, right? Threads on metal are like those grooves. They help connect and hold things together. But how do you make these threads with a metal lathe? Let’s dive into this fascinating process.

Did you know that metal lathes have been around for a long time? They started as wooden machines. Today, they are precise tools made of shiny metal. Learning to thread on a metal lathe opens up a world of projects. From car parts to jewelry, the possibilities are endless! Are you ready to learn and become a metal wizard?

How To Thread On A Metal Lathe: A Step-By-Step Guide

How to Thread on a Metal Lathe

Threading on a metal lathe can create precise screw threads for various projects. First, set up the lathe and select the right tool. Next, position the workpiece and make sure it’s secure. It’s crucial to align the cutting tool properly. Did you know that the quality of your thread can affect how well parts fit together? With practice, you can master this skill and make intricate pieces easily. Let’s explore threading techniques in detail!Understanding the Basics of Threading

Definition of threading in metalworking. Importance of threading in machining applications.Threading is like creating tiny grooves on metal pieces. These grooves let the pieces screw together nicely, much like twisting your favorite snack to open it. Without threading, machines would fall apart faster than a sandcastle at high tide! It plays a big role in many machining tasks, keeping everything tight and sturdy. It’s important for making parts that fit, hold, and function well, even if they promise not to run away!

| Term | Definition |

|---|---|

| Threading | Creating grooves for screws. |

| Importance | Ensures parts are secure and functional. |

Essential Tools and Equipment for Threading

List of necessary tools (e.g., lathe, threading tool, calipers). Safety gear and precautions to consider while threading.Getting ready to thread on a metal lathe? First, gather your essential tools! You’ll need a reliable lathe, a sharp threading tool, and precise calipers. Think of them as your trusty sidekicks! Don’t forget personal protective gear like goggles and gloves, because safety should always come first. Remember, a flying part can be scarier than a ghost on Halloween!

| Tool | Purpose |

|---|---|

| Lathe | Primary machine for threading |

| Threading Tool | Creates the threads |

| Calipers | Measures the threads accurately |

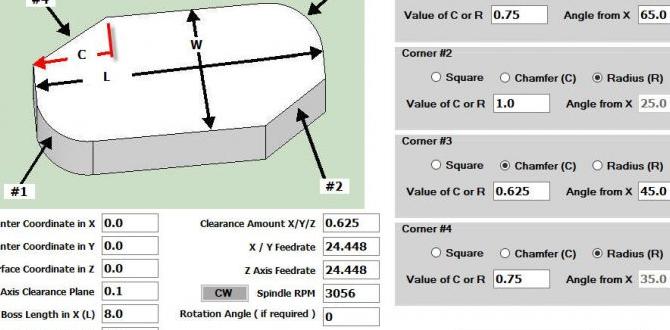

Setting Up Your Metal Lathe for Threading

Stepbystep process for preparing the lathe. Adjusting the spindle speed for optimal threading performance.First, make sure your metal lathe is clean and ready. Safety glasses on? Check! Next, secure the workpiece in the chuck tightly. You don’t want it dancing around while you work! Then, set the spindle speed. A good starting point for threading is around 300 RPM. This speed helps avoid mistakes and keeps the threading neat. If you go too fast, the metal might say “Nope!” and break!

| Step | Action |

|---|---|

| 1 | Clean the lathe |

| 2 | Secure the workpiece |

| 3 | Adjust spindle speed to ~300 RPM |

Choosing the Right Threading Tool

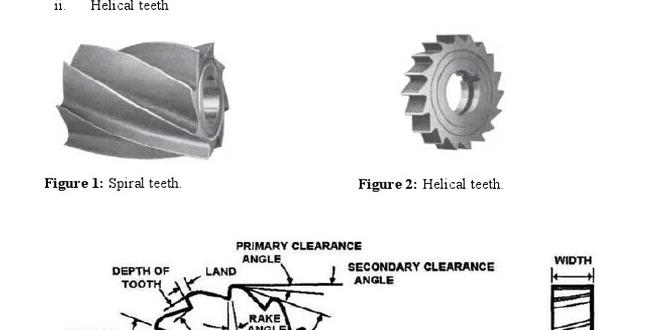

Description of various threading tools (e.g., single point vs. multipoint). Factors to consider when selecting a threading tool for your project.Different threading tools can help you create precise threads. There are single-point tools that cut one thread at a time and multipoint tools, which have several cutting edges for faster work. Consider these key points when choosing a tool:

- Project size

- Type of metal

- Desired thread details

- Cutting speed

Picking the right tool can make your threading task easier and more efficient!

What are the common threading tools?

Some common threading tools include tap tools, dies, and single-point cutting tools. Each serves a different purpose, but they all create threads!

Step-by-Step Guide to Threading on a Metal Lathe

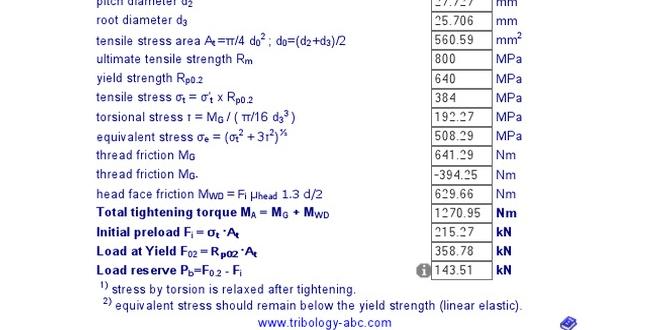

Detailed procedure for initiating the threading process. Techniques for achieving precise thread depths and pitches.Starting the threading process is all about preparation. First, make sure your metal lathe is clean and free from dust bunnies—yes, those sneaky little things do exist! Next, choose the right tool bit for the job. It should be sharp and ready to cut like a hot knife through butter. Adjust the lathe for the desired pitch and depth; remember, patience is key for perfect threads!

| Technique | Description |

|---|---|

| Depth Setting | Adjust the tool to cut a little at a time. |

| Pitch Control | Set the gears based on the thread size needed. |

Check your measurements often! It’s better to adjust than to redo. And if you mess up, don’t worry; every great machinist has a box of “learning experiences.” So grab your tool, keep it steady, and let those threads come to life!

Troubleshooting Common Threading Issues

Identification of typical problems (e.g., tool chatter, incorrect pitch). Solutions and adjustments to rectify threading issues.Threading on a metal lathe can face some common problems. You might notice issues like tool chatter or the wrong pitch. Here are some easy ways to fix them:

- Check tool sharpness—dull tools can chatter.

- Adjust the feed rate for a smoother cut.

- Make sure you set the correct pitch for threads.

- Tighten any loose parts on the lathe.

Try these tips, and you’ll see improvements in your threading work!

What causes tool chatter in threading?

Tool chatter happens when the cutting tool vibrates too much. It’s often due to a dull tool or incorrect speeds. Adjusting these factors can help reduce chatter.

How do I fix incorrect pitch in threading?

Check the settings on your lathe. Ensure you have the correct gear ratio or threading dial set to avoid incorrect pitch.

Maintenance Tips for Your Metal Lathe

Regular maintenance practices to ensure lathe longevity. Importance of tool care and replacement.Keeping your metal lathe in good shape is important. Regular maintenance helps it last longer. Clean the lathe after each use. Check the oil levels often to keep it running smoothly. Replace worn tools as needed; this keeps your work accurate. Here are some quick tips:

- Clean the machine after each job.

- Check and refill oil regularly.

- Inspect tools for wear and replace them promptly.

Remember, a well-maintained lathe makes better threads!

Why is regular maintenance important?

Regular maintenance keeps your lathe working well and safe. It can prevent bigger problems in the future. Taking care of your tools means better results in your projects.

Applications of Threading in Various Industries

Exploration of industries that utilize threaded components. Examples of projects that can benefit from precise threading.Many industries rely on threaded parts to get the job done right. From cars to airplanes, threading can hold pieces together, making everything work smoothly. For example, in construction, precise threading helps secure bolts that support heavy beams. In kitchen appliances, it keeps your blender safe. Without threading, our world might fall apart—literally! Imagine your favorite light bulb falling down because it wasn’t threaded properly. Yikes!

| Industry | Threaded Components |

|---|---|

| Automotive | Bolts, screws for engine parts |

| Aerospace | Fasteners in aircraft structures |

| Construction | Supports in building frameworks |

| Home Appliances | Components in product assembly |

Conclusion

Threading on a metal lathe is an important skill. We learned the importance of setting up the lathe properly, using correct tools, and practicing safety. Always measure carefully and start slow. With practice, you’ll get better. Explore more guides to improve your skills. Keep learning, and threading will become easier.FAQs

Sure! Here Are Five Related Questions On The Topic Of Threading On A Metal Lathe:Threading on a metal lathe means making spiral grooves or ridges on metal. We use these grooves to create screws or bolts. When using a lathe, you can carefully control the cutting tool to shape the metal. It’s important to go slow and be safe while working. Always wear safety glasses to protect your eyes!

Sure! Please share the question you would like me to answer.

What Types Of Threading Tools Are Commonly Used On A Metal Lathe, And How Do They Differ From One Another?On a metal lathe, we commonly use threading tools like taps, dies, and threading inserts. Taps help create internal threads inside holes. Dies are used to cut external threads on rods. Threading inserts can be swapped out easily and are great for making different thread shapes. Each tool works for different tasks, so we choose based on what we need!

How Do You Set The Correct Pitch And Diameter For Threading A Specific Bolt Or Nut On A Metal Lathe?To set the correct pitch and diameter for threading a bolt or nut on a metal lathe, start by measuring the bolt or nut. You can use a caliper to get the diameter. Next, find out the thread pitch, which is the distance between threads. Adjust the lathe settings to match these measurements. Finally, test the threading on a piece of scrap metal to make sure it fits right.

What Are The Steps Involved In Setting Up A Metal Lathe For Cutting Threads, Including Adjustments To The Carriage And Tailstock?To set up a metal lathe for cutting threads, first, we need to attach the right cutting tool. Next, you adjust the carriage so it can move the tool in a straight line. You also need to set the tailstock to hold the end of the metal piece tightly. Finally, we check the speed settings and make sure everything is aligned properly. Now, you’re ready to start cutting threads!

How Can You Ensure That The Thread Depth And Profile Are Accurate And Uniform Throughout The Entire Length Of The Threaded Area?To make sure the thread depth and shape are the same all along, you should measure carefully. Use a ruler or caliper to check the depth often. It’s also important to keep the tool steady while you cut the threads. Lastly, practice makes perfect! Repeat your work and check it each time until you get it right.

What Common Mistakes Should Be Avoided When Threading On A Metal Lathe To Prevent Scrap Or Damage To The Workpiece?When using a metal lathe to make threads, you should avoid a few simple mistakes. First, make sure your tools are sharp. Dull tools can hurt the metal and ruin your work. Second, always check the speed of the lathe. Too fast can cause problems. Lastly, pay attention to how deep you cut. Cutting too deep can break the metal and make scrap.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Threading On A Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Threading on a metal lathe means making spiral grooves or ridges on metal. We use these grooves to create screws or bolts. When using a lathe, you can carefully control the cutting tool to shape the metal. It’s important to go slow and be safe while working. Always wear safety glasses to protect your eyes!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Types Of Threading Tools Are Commonly Used On A Metal Lathe, And How Do They Differ From One Another?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “On a metal lathe, we commonly use threading tools like taps, dies, and threading inserts. Taps help create internal threads inside holes. Dies are used to cut external threads on rods. Threading inserts can be swapped out easily and are great for making different thread shapes. Each tool works for different tasks, so we choose based on what we need!”}},{“@type”: “Question”,”name”: “How Do You Set The Correct Pitch And Diameter For Threading A Specific Bolt Or Nut On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set the correct pitch and diameter for threading a bolt or nut on a metal lathe, start by measuring the bolt or nut. You can use a caliper to get the diameter. Next, find out the thread pitch, which is the distance between threads. Adjust the lathe settings to match these measurements. Finally, test the threading on a piece of scrap metal to make sure it fits right.”}},{“@type”: “Question”,”name”: “What Are The Steps Involved In Setting Up A Metal Lathe For Cutting Threads, Including Adjustments To The Carriage And Tailstock?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe for cutting threads, first, we need to attach the right cutting tool. Next, you adjust the carriage so it can move the tool in a straight line. You also need to set the tailstock to hold the end of the metal piece tightly. Finally, we check the speed settings and make sure everything is aligned properly. Now, you’re ready to start cutting threads!”}},{“@type”: “Question”,”name”: “How Can You Ensure That The Thread Depth And Profile Are Accurate And Uniform Throughout The Entire Length Of The Threaded Area?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make sure the thread depth and shape are the same all along, you should measure carefully. Use a ruler or caliper to check the depth often. It’s also important to keep the tool steady while you cut the threads. Lastly, practice makes perfect! Repeat your work and check it each time until you get it right.”}},{“@type”: “Question”,”name”: “What Common Mistakes Should Be Avoided When Threading On A Metal Lathe To Prevent Scrap Or Damage To The Workpiece?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe to make threads, you should avoid a few simple mistakes. First, make sure your tools are sharp. Dull tools can hurt the metal and ruin your work. Second, always check the speed of the lathe. Too fast can cause problems. Lastly, pay attention to how deep you cut. Cutting too deep can break the metal and make scrap.”}}]}