Have you ever wondered how machines are made? Metal lathes play a key role in this process. They help shape and cut metal into precise forms. But there’s more to using a metal lathe than just turning a piece of metal. Understanding metal lathe torque is essential for getting the best results.

Torque sounds complicated, right? But it’s simply the force that helps turn the lathe. Imagine trying to open a really tight jar lid. You need to apply just the right amount of force. That’s what torque does for your lathe.

Using metal lathe torque properly can make your work easier. It helps prevent mistakes and accidents. Plus, you’ll create better and more precise parts. In this article, we will explore how to use metal lathe torque without confusion. You’ll learn tips and tricks that make it simple and fun. Are you ready to dive in and discover more?

How To Use Metal Lathe Torque For Precision Machining

How to Use Metal Lathe Torque

Using a metal lathe involves mastering torque for the best results. Torque is the twisting force that allows the lathe to cut smoothly. Understanding how to adjust torque affects your projects’ precision and safety. Without the right settings, you could damage materials or tools. Did you know that just a slight change in torque can impact how cleanly a piece is cut? By learning to balance torque correctly, you can make beautiful and accurate parts. Remember, practice makes perfect!Understanding Metal Lathe Torque

Definition of torque in metal lathe operations. Importance of torque for precision and safety.Torque is the magic force that helps a metal lathe turn metal into wonderful shapes. It’s like giving the lathe a gentle push to get things moving. Having the right amount of torque matters a lot for smooth operation. Too little and your project can turn into a wobbly mess. Too much torque? You could damage your materials. Think of torque as Goldilocks—she’s looking for the “just right” amount! So keep it balanced for precision and safety.

| Torque Level | Effect |

|---|---|

| Too Low | Wobbly results |

| Just Right | Perfect finish! |

| Too High | Potential damage |

Calculating the Required Torque

Formula for calculating torque based on material and tool specifications. Factors to consider for different materials.To get the right torque, you can use a simple formula: Torque = Force x Distance. This formula helps when working with different materials and tools. Each material needs a different amount of torque. Here are some factors to think about:

- Material type: Harder materials require more torque.

- Tool sharpness: Sharp tools need less torque.

- Diameter: A thicker part may need more torque.

Calculating torque is key for safe metal lathe usage. Always take your time to find the correct numbers.

How do you calculate torque for different materials?

To calculate torque for different materials, always consider how hard the material is. A simple method is to adjust your force based on material strength.Choosing the Right Settings for Torque Adjustment

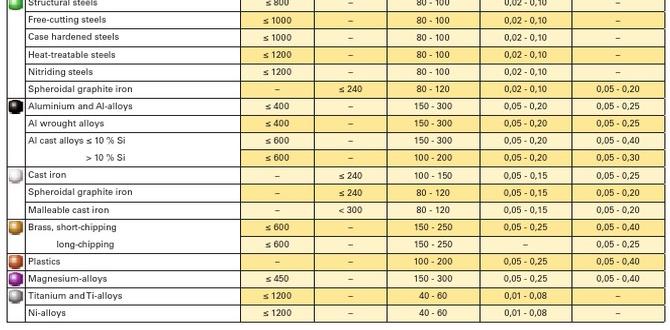

Recommended settings for various materials and projects. Tips for adjusting speed and feed rates for optimal torque.Getting your settings right is key to using a metal lathe like a pro! For different materials, you’ll want specific torque adjustments. For soft metals like aluminum, start with a lower torque. For harder materials like steel, turn it up a notch. Always consider your speed and feed rates too. Faster speeds mean less torque, while slower feeds might demand more. Here’s a handy chart:

| Material | Recommended Torque | Speed (RPM) | Feed Rate (inches/rev) |

|---|---|---|---|

| Aluminum | Low | 600-1000 | 0.005-0.010 |

| Brass | Medium | 500-800 | 0.005-0.012 |

| Steel | High | 300-600 | 0.001-0.005 |

Remember, adjusting settings is like baking a cake. Too much or too little can make the project a flop! So, check your lathe and have fun crafting!

Common Mistakes to Avoid When Using Torque

Errors in torque application that can lead to damaged tools or workpieces. How to identify and rectify torquerelated issues in machining.Using torque correctly is key to keeping your tools and workpieces safe. A common mistake is applying too much force. This can cause damage. Another mistake is not checking the torque settings regularly. This oversight can lead to inaccurate machining. Always pay attention to how tight you make things, and check your tools for wear. Identify issues quickly to prevent bigger problems.

What are the main torque mistakes?

Common mistakes include:

- Using the wrong torque wrench.

- Ignoring manufacturer guidelines.

- Forgetting to recalibrate tools.

Correcting torque errors helps keep everything working smoothly. With care, you can avoid costly repairs and maintain your tools.

Enhancing Your Metal Lathe Skills Through Practice

Suggested projects for beginners to understand torque application. Advanced techniques to master torque for complex tasks.Practice can make you an expert on a metal lathe. Start with simple projects to learn how to use torque. Here are a few ideas:

- Make a wooden knob. This will help you get a feel for torque control.

- Create a small metal hazel nut. This adds complexity and teaches torque adjustments.

- Try working on a keychain. It’s simple but useful.

Once comfortable, move to advanced tasks, like machining gears. Use torque settings to understand how much pressure is needed. Remember, practice leads to confidence and better skills.

What are good beginner projects for metal lathe?

Good beginner projects include making knobs, small parts, and keychains. These help you learn torque and control skills.

How can one master torque for advanced projects?

To master torque, practice with complex projects like gears and pulleys. Understanding torque settings will improve your work.

Maintenance Tips for Optimal Torque Performance

Regular checks and maintenance practices for lathe components. Importance of lubrication and cleanliness in torque efficiency.To keep your lathe running well, you need regular checks and care. Ensure all parts are in good shape. Look for wear and tear that could affect performance. Clean all areas, as dirt can reduce torque efficiency. Proper lubrication is essential. Oil helps parts move smoothly, boosting performance. Follow these simple tips for optimal torque:

- Check belts and gears regularly.

- Keep all surfaces clean.

- Lubricate as needed to avoid friction.

Why is lubrication important?

Lubrication reduces friction and wear on lathe parts, leading to better torque and longer life for the machine.

Resources for Further Learning

Recommended books and online courses on metal lathe operations. Useful forums and communities for metalworking enthusiasts.Learning about metal lathe operations can be exciting! Here are some resources to help you grow your skills:

- Books:

- “Metal Lathe for Beginners” – A clear introduction.

- “Advanced Metalworking Techniques” – For those ready to dive deeper.

- Online Courses:

- Udemy: Offers courses on metal lathe basics and advanced skills.

- Coursera: Courses by universities on machining and metalwork.

- Forums and Communities:

- Reddit: Join the r/Metalworking for tips and advice.

- Metalworking Community: A great space to share and learn.

These resources are fantastic for anyone interested in metal lathes. Dive in and connect with others who share your passion!

What are some useful resources for metal lathe learning?

Books, online courses, and community forums are great resources for learning metal lathe operations. Explore books dedicated to beginners and advanced students. Websites like Udemy and Reddit can connect you with many people and valuable lessons.

Conclusion

In conclusion, using metal lathe torque is essential for safe and effective machining. Remember to adjust the torque based on the material you’re working with. Always check your machine’s manual for specific settings. Practice correct techniques to avoid mistakes. For more tips, consider reading beginner guides or watching tutorials. Let’s start creating with confidence!FAQs

What Is The Recommended Torque Setting For Different Materials When Using A Metal Lathe?When using a metal lathe, the torque setting changes based on the material. For soft metals like aluminum, use low torque settings. For harder metals like steel, you need higher torque. Always start with lower torque and adjust if needed. Remember, each material needs a different touch!

How Can I Accurately Measure Torque While Operating A Metal Lathe?To measure torque on a metal lathe, you can use a torque wrench. This tool tells you how much twisting force you apply. You attach it to the handle of the lathe. As you turn the handle, the wrench shows the torque amount. Make sure to check your wrench’s settings to get accurate results.

What Factors Influence The Torque Requirements When Machining On A Metal Lathe?When you use a metal lathe, several factors affect how much twisting force, or torque, you need. First, the type of metal matters; harder metals require more torque. Next, the size of the tool you’re using can change the torque required. If you’re cutting deeper, you’ll also need more torque. Plus, how fast you want to work and the shape of the item can influence torque.

How Do I Determine The Maximum Torque Capacity Of My Metal Lathe?To find the maximum torque of your metal lathe, look at the manual. It usually gives the maximum torque number. You can also check the motor’s specifications. If you don’t have the manual, search online with your lathe’s model number. This will help you learn about its torque capacity.

What Are The Consequences Of Using Incorrect Torque Settings On A Metal Lathe?If you use the wrong torque settings on a metal lathe, it can be a big problem. The machine might not hold the pieces tightly, making them move around. This can lead to bad cuts, mistakes, or even damage to the lathe. You could hurt yourself or make things that don’t fit right. Always check your settings to keep everything safe and working well.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Is The Recommended Torque Setting For Different Materials When Using A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, the torque setting changes based on the material. For soft metals like aluminum, use low torque settings. For harder metals like steel, you need higher torque. Always start with lower torque and adjust if needed. Remember, each material needs a different touch!”}},{“@type”: “Question”,”name”: “How Can I Accurately Measure Torque While Operating A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To measure torque on a metal lathe, you can use a torque wrench. This tool tells you how much twisting force you apply. You attach it to the handle of the lathe. As you turn the handle, the wrench shows the torque amount. Make sure to check your wrench’s settings to get accurate results.”}},{“@type”: “Question”,”name”: “What Factors Influence The Torque Requirements When Machining On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use a metal lathe, several factors affect how much twisting force, or torque, you need. First, the type of metal matters; harder metals require more torque. Next, the size of the tool you’re using can change the torque required. If you’re cutting deeper, you’ll also need more torque. Plus, how fast you want to work and the shape of the item can influence torque.”}},{“@type”: “Question”,”name”: “How Do I Determine The Maximum Torque Capacity Of My Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the maximum torque of your metal lathe, look at the manual. It usually gives the maximum torque number. You can also check the motor’s specifications. If you don’t have the manual, search online with your lathe’s model number. This will help you learn about its torque capacity.”}},{“@type”: “Question”,”name”: “What Are The Consequences Of Using Incorrect Torque Settings On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you use the wrong torque settings on a metal lathe, it can be a big problem. The machine might not hold the pieces tightly, making them move around. This can lead to bad cuts, mistakes, or even damage to the lathe. You could hurt yourself or make things that don’t fit right. Always check your settings to keep everything safe and working well.”}}]}