Have you ever wondered how metal parts are made so perfectly? One incredible tool that makes this possible is the industrial metal lathe quill. This special part of a lathe helps create precise shapes and cuts in metal. Imagine building something cool from metal, like a robot or a model car!

The quill works by holding tools that carve the metal as it spins. It allows for amazing detail and accuracy. Did you know that with the right skills, a metal lathe can turn a simple block of metal into a masterpiece?

People in factories and workshops use industrial metal lathes every day. These machines help them build everything from tiny screws to large engine parts. It’s fascinating how much we rely on these tools!

In this article, we will explore what makes the industrial metal lathe quill so special. We will uncover its parts, how it works, and the many things you can create with it. Get ready to dive into the world of metalworking!

Understanding the Industrial Metal Lathe Quill

The **industrial metal lathe quill** is a crucial part of lathes used in machining. It holds the cutting tool and can move in and out to adjust depths. Imagine carving a wooden figure; the quill lets you change how deep the tool goes, similar to adjusting the knife’s pressure. Understanding its function improves precision in projects. Did you know that small changes in quill settings can significantly impact the final product? Learning about the quill helps you master your metalworking skills.

What is an Industrial Metal Lathe Quill?

Definition and function of a quill in metal lathes.. Importance of quill in machining processes..

A quill is a key part of a metal lathe, acting like a trusty sidekick. It holds the cutting tool, helping it spin and slice through metal like a hot knife through butter. Think of it as the arm of the lathe; it extends to reach the materials and bring your metal creations to life. The quill is super important in machining processes because it ensures precision and control. A precise quill helps avoid mistakes that can turn a masterpiece into a metal mess!

| Function of Quill | Importance |

|---|---|

| Holds cutting tool | Ensures precision |

| Helps with movement | Improves control |

Key Features of a Quality Quill

Precision and accuracy: critical measurements to consider.. Durability and wear resistance features..

Quality in an industrial metal lathe quill comes from two main features. First, precision and accuracy matter greatly. They help create exact measurements for your projects. Second, durability is key. A strong quill resists wear and tear, lasting longer in tough conditions. Look for these qualities to ensure you get the best quill.

What makes a quill precise and durable?

To be precise, a quill must be finely tuned. For durability, it should be made from hard materials like steel.

Key Features:

- Precision measures for accuracy

- Durable materials resist damage

How to Choose the Right Quill for Your Metal Lathe

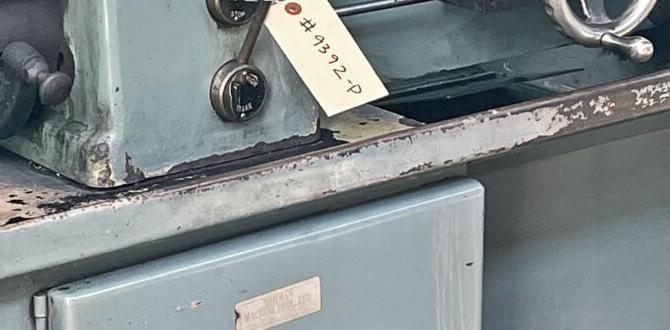

Factors to consider: size, compatibility, and intended use.. Common brands and models to look out for..

Choosing the right quill for your metal lathe is a big deal, like picking the best ice cream flavor. First, consider size. It should match your lathe perfectly. If it’s too big, it’ll feel like wearing shoes two sizes too big! Next, think about compatibility. Ensure it fits with your machine’s specifications. Finally, decide your intended use. Are you crafting small toys or giant robots? Knowing this helps! Popular brands to check out include Jet, Grizzly, and South Bend. They make quality quills that don’t bite back!

| Brand | Model | Features |

|---|---|---|

| Jet | JWL-1442VS | Variable speed control |

| Grizzly | G1006 | Heavy-duty construction |

| South Bend | SB1016 | Precision cutting |

Maintenance Tips for Metal Lathe Quills

Best practices for cleaning and lubrication.. Signs of wear and when to replace the quill..

Keeping an industrial metal lathe quill in great shape helps ensure it works well. Clean it regularly with a soft cloth to remove dirt and grease. Use a suitable lubricant like oil to keep the parts moving smoothly. Watch for signs of wear, such as unusual noises or sticking parts. If you notice cracks or damage, replace the quill right away to avoid further problems.

What are the best practices for cleaning and lubrication?

Regularly clean and lubricate your quill to prevent wear. Here are some tips:

- Use a soft cloth.

- Apply appropriate oil.

- Check for debris often.

How can I tell when it’s time to replace the quill?

Look for damage, noise, or sticking parts. These could mean it’s time for a new one.

Common Issues with Industrial Metal Lathe Quills

Identifying problems: uneven cutting, vibrations, and misalignment.. Troubleshooting tips for resolving quillrelated issues..

Common problems can show up when using an industrial metal lathe quill. You might see uneven cutting, vibrations, or misalignment. These issues can make your work less accurate. To fix them, check a few things:

- Look for dirt or damage on the quill.

- Ensure all screws are tight.

- Examine the cutting tools; they should be sharp and aligned.

- Test the lathe’s speed settings.

By following these steps, you can improve your lathe’s performance and keep it working well.

What are some common issues with a lathe quill?

Some issues include uneven cutting, vibrations, and misalignment. These problems often lead to poor results. Always check your equipment for any easy fixes before calling a professional.

Advanced Applications of Quills in Metalworking

Unique machining techniques utilizing specialized quills.. Innovations in quill technology and their impact on industry..

Quills dramatically change how we work with metal. In metalworking, unique techniques pop up thanks to specialized quills. For instance, they allow for deeper cuts while keeping things steady. Talk about precision! New inventions in quill technology mean faster production and less waste. Who doesn’t like saving time and materials? Check out the table below for some cool innovations:

| Innovation | Description |

|---|---|

| Automatic Feed | Allows quills to move smoothly without manual help. |

| CNC Compatibility | Connects quills to computers for precise control. |

| Multi-Axis Movement | Enables complex designs in less time. |

These advancements are shaking up the industry. With every new quill, there’s a chance to take metalworking to the next level. Isn’t that awesome?

Conclusion

In summary, an industrial metal lathe quill helps shape and support materials during machining. It enhances precision in tasks like drilling and turning. Understanding its role can improve your projects. If you’re interested, consider exploring detailed guides or videos about lathe operations. This knowledge will boost your skills and confidence in using lathes effectively.

FAQs

What Is The Purpose Of A Quill In An Industrial Metal Lathe?

A quill in an industrial metal lathe helps hold and move tools. It lets you change the tool quickly when you need to. By moving up and down, the quill helps cut the metal accurately. This makes it easier for you to create the shapes you want.

How Does The Design Of A Quill Affect The Precision And Accuracy Of Machining Operations?

The design of a quill is very important in machining. A good quill helps the machine move smoothly. This makes it easier to make precise cuts. If the quill is wobbly or not strong, it can lead to mistakes. So, we want a solid design to stay accurate in our work.

What Are The Common Materials Used In Manufacturing Quills For Metal Lathes, And Why Are They Chosen?

Quills for metal lathes are usually made from steel and aluminum. Steel is strong and can handle heavy stuff. Aluminum is lighter and easier to move around. We choose these materials because they help the quills last a long time and work well.

How Can Operators Ensure Proper Maintenance And Longevity Of The Quill In A Metal Lathe?

To keep the quill in a metal lathe working well, you should clean it regularly. Always check for dirt or oil and wipe it down. You can also add a little oil to keep it smooth. Make sure to use the lathe carefully so it doesn’t get damaged. Lastly, store it in a safe place when you’re not using it.

What Are The Differences Between Fixed And Sliding Quills In Metal Turning Applications?

Fixed quills stay in one place, while sliding quills can move up and down. In metal turning, fixed quills help hold the tool steady. Sliding quills let you adjust the tool easier for different shapes. This makes it simpler to work on various metal pieces. Each type has its own uses depending on what we need to do.