Have you ever wondered how to make your metal lathe more precise? Installing a Digital Read Out (DRO) on your lathe can change everything. Imagine being able to see exact measurements easily. It can turn a good project into a great one!

Installing a DRO might sound tricky, but it’s simpler than you think. Many people use lathes for metalworking. Yet, not everyone knows how to get the best results from them. That’s where a DRO comes in handy. With this tool, you can work smarter and faster.

Did you know that some professional machinists claim a DRO saves them hours on each project? That’s true! Taking the time to install it will pay off in the end. Let’s explore how to install a DRO on your metal lathe step-by-step. Ready to boost your skills? Let’s dive in!

Installing Dro On Metal Lathe: A Comprehensive Guide

Installing a Digital Readout (DRO) on a metal lathe can greatly enhance accuracy in your projects. It turns confusing measurements into clear readouts. Start by gathering tools and materials, including the DRO unit and mounting brackets. Carefully follow the instructions to attach the readout to your lathe. Imagine cutting metal with precision—no more guesswork! With a DRO, even beginners can achieve professional results. Curious how it all works? Let’s dive into the steps together!

Understanding DRO Systems

Definition and purpose of Digital Readout (DRO) systems. Types of DRO systems available for metal lathes.

Digital Readout (DRO) systems help you see measurements clearly on metal lathes. They make cutting and shaping metal easier. With DRO, you can measure size quickly, which improves accuracy and saves time. There are different types of DRO systems:

- 2-axis systems for basic tasks.

- 3-axis systems for more complex work.

- Advanced systems with digital displays for better precision.

Knowing which system works best can make your job easier.

What is the purpose of a DRO system?

A DRO system shows real-time measurements, helping users cut metal accurately.

Why are different types of DRO systems important?

Different DRO systems meet various needs. More axes allow for complex shapes.

Benefits of Installing a DRO on Your Metal Lathe

Enhanced precision and accuracy in machining. Improved efficiency and time savings.

Adding a DRO to your metal lathe can feel like upgrading from a bicycle to a spaceship. With enhanced precision, you’ll get accurate measurements every time, which means fewer mistakes. Think of it as the difference between guessing your pizza slice size and using a protractor—definitely more toppings for you! Plus, you’ll save waste and time, making your work much more efficient. Why toil over the machine when a DRO can do the math for you?

| Benefit | Explanation |

|---|---|

| Enhanced Precision | Less guesswork means better results. |

| Improved Efficiency | Quicker setups lead to more time for pizza! |

Choosing the Right DRO for Your Metal Lathe

Key features to consider when selecting a DRO. Comparison of popular DRO brands and models.

Picking the right DRO can make your metal lathe much better. Key features to think about are display size, accuracy, and installation ease. Some top brands are:

- Mitutoyo

- Integral

- SINO

Each brand has different models. For instance, Mitutoyo is known for accuracy, while SINO offers good value. Think about what you need. A good DRO saves time and helps you work smarter.

What should you consider when choosing a DRO?

Consider display size, accuracy, and ease of use.

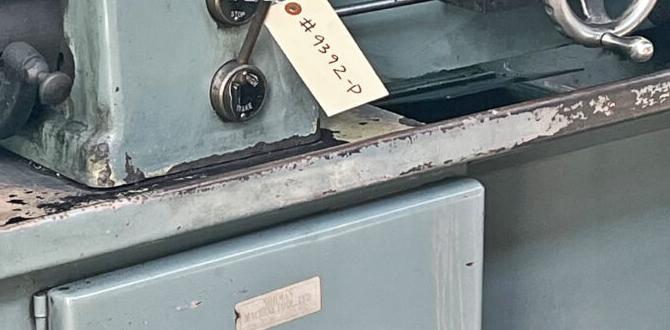

Preparing Your Metal Lathe for DRO Installation

Tools and materials required for installation. Steps to ensure your lathe is ready for the DRO.

Before installing a DRO on your metal lathe, you need to gather some tools and materials. Here’s a list to help you:

- Measuring tape

- Drill

- Wrenches

- Screwdriver

- Mounting brackets

- Power supply

Next, ensure your lathe is clean and level. This step is very important for accurate readings. Check that the machine is turned off and unplugged. Secure all parts tightly. This will make the installation easier and help your DRO work better.

What tools do you need for DRO installation?

You need a measuring tape, drill, wrenches, screwdriver, mounting brackets, and a power supply.

Step-by-Step Guide to Installing a DRO

Detailed installation process for the digital readout system. Tips for proper alignment and calibration.

To install a digital readout (DRO) system on your metal lathe, start by gathering your tools and the DRO kit. First, attach the scales to your lathe; make sure they’re level and secure. Next, connect the display unit, usually mounted on the front. Afterward, carefully align everything. A crooked setup can lead to mistakes, and nobody likes a wobbly machine! Lastly, calibrate it by following the manufacturer’s instructions, ensuring accurate readings.

| Step | Details |

|---|---|

| 1 | Gather tools and DRO kit. |

| 2 | Attach scales securely. |

| 3 | Connect and mount display unit. |

| 4 | Align everything carefully. |

| 5 | Calibrate using instructions. |

Remember, proper alignment and calibration are key. They can save you from accidentally turning a metal block into Swiss cheese!

Configuring Your DRO for Optimal Use

Initial setup settings for different machining tasks. How to calibrate and finetune your DRO.

To kick off your journey with a DRO, first, you need to get comfy with its settings. Each machining task has its own tricks. Set your DRO according to the task; you wouldn’t wear winter clothes in summer, right? Calibrating is key! Make adjustments until those readings are on point. Check out this handy table for different setups:

| Task | Initial Settings |

|---|---|

| Turning | XYZ Axis Setup |

| Milling | Feed Rate Calibration |

Finishing touches are where the magic happens. Fine-tune your settings, and you’ll feel like a wizard on a metal lathe. Happy machining!

Common Issues and Troubleshooting Tips

Typical problems encountered during installation. Solutions and maintenance tips for keeping your DRO functioning.

Many people face problems during installation. Here are some common issues:

- Misalignment of the DRO. This can cause inaccurate readings.

- Electrical connections that are loose or faulty.

- Incorrect software settings, leading to errors.

To solve these problems, first, check all connections. Ensure that your DRO is aligned properly. Regular cleaning helps keep the sensors functioning smoothly. Always refer to the manual for proper maintenance instructions.

What are the frequent problems when installing a DRO?

Frequent problems include misalignment, loose wiring, and incorrect software settings.

What tips can help maintain my DRO?

- Regularly check connections.

- Clean sensors gently.

- Update software as needed.

Upgrading Your Metal Lathe with Advanced Features

Additional capabilities to consider adding to your DRO. Futureproofing your investment in DRO technology.

Adding advanced features to your metal lathe can make it more useful and enjoyable. For instance, upgrading your Digital Readout (DRO) can boost accuracy and efficiency. Think about these options:

- Scale upgrades: Improve measurements with better scales.

- Touchscreen interface: Easier navigation between settings.

- Digital storage: Save your settings for future jobs.

These improvements keep your investment strong and ready for the future. It’s smart to plan for changes in technology as this helps your lathe stay relevant.

Why upgrade features on your DRO?

Upgrading features on your DRO enhances productivity and precision, making your work easier and faster.

Conclusion

In conclusion, installing a DRO on your metal lathe enhances accuracy and efficiency. You can easily measure cuts and improve your projects. Remember to choose the right DRO and follow the installation guide carefully. With practice, you’ll notice better results in your work. So, gather your tools and get started! For more tips, check out related articles or videos.

FAQs

Sure! Here Are Five Related Questions On The Topic Of Installing A Digital Readout (Dro) On A Metal Lathe:

Sure! Here are five questions about installing a Digital Readout (DRO) on a metal lathe: 1. What is a Digital Readout (DRO)? 2. How do we choose the right DRO for our lathe? 3. Can we install the DRO ourselves? 4. What tools do we need for the installation? 5. How do we set up the DRO after installing it?

Sure! Please provide the question you’d like me to answer.

What Are The Essential Components Needed For Installing A Dro On A Metal Lathe?

To install a DRO, or Digital Read Out, on a metal lathe, you need a few important parts. First, get the DRO display unit. This shows you the measurements. Next, you need scales that measure movement. These attach to the lathe. Lastly, you will need brackets and cables to put everything together. Don’t forget the tools to mount the parts!

How Do You Choose The Appropriate Dro System For Your Specific Metal Lathe Model?

To choose the right Digital Readout (DRO) system for your metal lathe, first, check your lathe’s model. Then, look for a DRO that fits its size and features. You want a DRO that is easy for you to read and use. Ask for help or read reviews to find the best option. Always make sure it works well with your specific lathe.

What Are The Steps Involved In Accurately Mounting The Scale And Readout Units On The Lathe?

To mount the scale and readout units on the lathe, start by cleaning the area where you will attach them. Then, position the scale so it lines up with the lathe bed. Use screws to secure the scale tightly. Next, attach the readout unit to a comfortable spot where you can easily see it. Finally, check to make sure everything is straight and works correctly before using the lathe.

How Do You Calibrate The Dro After Installation To Ensure Accurate Measurements?

To calibrate the Digital Readout (DRO) after you install it, first, check the machine’s zero point. Next, move the machine to a known measurement, like one inch or ten centimeters. Use a ruler or caliper to check if the DRO shows the same number. If it does not, adjust the DRO settings until it matches your measurement. Repeat this until everything is correct for accuracy.

What Common Challenges Might Arise During The Installation Of A Dro On A Metal Lathe, And How Can They Be Addressed?

When installing a Digital Readout (DRO) on a metal lathe, you might face a few problems. First, it can be hard to find the right places to put the sensors. You can solve this by carefully measuring and planning where everything goes. Second, connecting the wiring might be tricky, but you can take your time and follow the instructions. Lastly, if the DRO doesn’t turn on, you should check all your connections to make sure they are secure.