Have you ever wondered how metal objects are shaped and molded? A kit metal lathe pulley plays a key role in this process. Imagine a carpenter using his tools to create something amazing. That’s similar to what a lathe does in metalworking.

These lathes spin metal pieces and shape them into exact designs. The pulley helps manage the machine’s speed. This way, you can make precise cuts. Isn’t it fascinating how this simple part makes a big difference?

In this article, you will discover more about kit metal lathe pulleys. We’ll explore how they work and why they are important. You might even learn how to use one in a project!

Kit Metal Lathe Pulley: Essential Components And Benefits

Understanding Kit Metal Lathe Pulley

A kit metal lathe pulley is vital for anyone into metalworking. It enhances the lathe’s performance and controls speed effectively. Imagine creating a perfect piece of metal art! By using a reliable pulley, you can improve precision and efficiency. Did you know that the right pulley can save you time? This simple component can boost your project’s success. Explore different styles to find what suits your needs best. Enjoy turning ideas into reality with a quality metal lathe pulley!Understanding Kit Metal Lathe Pulleys

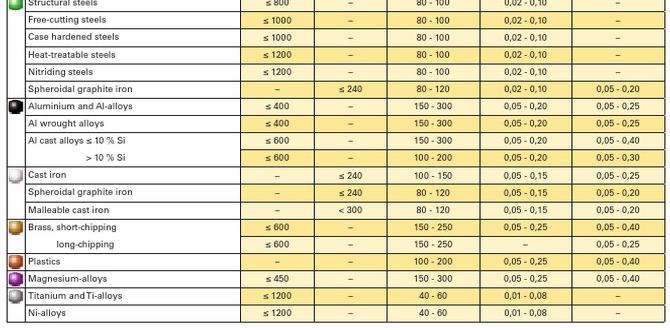

Definition and purpose of metal lathe pulleys. Different types and sizes of pulleys used in metal lathes.Metal lathe pulleys are important parts of machines that help shape metal. They transfer power from the motor to the lathe, which makes cutting easier. There are different types and sizes of pulleys to fit various lathes. Here are a few examples:

- Standard pulleys: These are common and simple.

- Variable speed pulleys: These allow for speed changes.

- Half-speed pulleys: These reduce the speed for finer work.

Each type serves a different purpose, making lathes more efficient and versatile.

What is the function of metal lathe pulleys?

Metal lathe pulleys help connect the motor to the lathe. This connection allows the lathe to turn and cut metal smoothly. Without pulleys, the machine wouldn’t work properly.

Choosing the Right Kit for Your Metal Lathe

Factors to consider when selecting a pulley kit. Compatibility with various metal lathe models.Picking the right pulley kit for your metal lathe is important. You want to make sure it fits well and works great. Here are some factors to think about:

- Compatibility: Will it fit your metal lathe model?

- Material Quality: Is it strong and durable?

- Size: Does it match your lathe’s requirements?

- Ease of Installation: Can you set it up easily?

Choosing wisely helps your lathe run smoothly and last longer.

What factors should I consider when selecting a pulley kit?

Consider compatibility with your lathe model, material quality, and ease of installation.

Will any pulley kit work with my metal lathe?

No, always check if the kit is compatible with your specific lathe model.

Installation Process for Metal Lathe Pulleys

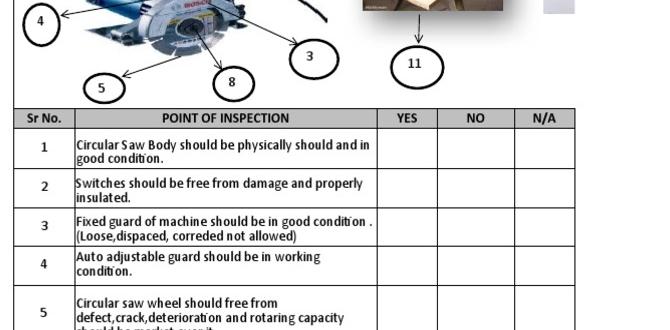

Stepbystep installation guide. Common pitfalls and how to avoid them.Installing a metal lathe pulley can feel like building a LEGO set—fun, but sometimes tricky! Start by ensuring you have all the parts. Follow these simple steps:

| Step | Action |

|---|---|

| 1 | Gather tools and components. |

| 2 | Remove the old pulley—careful, it might be stuck! |

| 3 | Position the new pulley correctly. |

| 4 | Tighten screws, but not too tight, or you’ll turn it into a flat tire! |

| 5 | Test it out—make sure it spins smoothly. |

A common pitfall? Forgetting to check for proper alignment. This can lead to loud noises or worse—pulley malfunctions! Always double-check before you start. With these tips, you’ll be a metal lathe pulley pro in no time!

Adjustment and Tuning of Metal Lathe Pulleys

Importance of proper alignment and tensioning. Techniques for optimal performance.Keep your lathe pulleys happy, and they will keep your projects running smoothly! Proper alignment and tensioning are key. If they’re off, your projects could go “bumpy.” Check if your pulley is aligned straight like a soldier. Tighten those belts just right—too loose won’t cut it, and too tight could snap faster than a rubber band! Here’s a quick table on how to tune your lathe pulleys:

| Tension Level | Result |

|---|---|

| Too Loose | Slipping belts! |

| Just Right | Smooth sailing! |

| Too Tight | Snap, crackle, pop! |

Keep checking your setup. A properly tuned lathe can make precision cuts that’ll have you feeling like a rock star in the workshop. Remember, a little adjustment goes a long way!

Maintenance Tips for Longevity of Metal Lathe Pulleys

Routine checks and maintenance tasks. Signs of wear and when to replace.Keeping your metal lathe pulleys in good shape is easier than you might think. Regular checks are key. Look for cracks, wear, or strange noises. If it sounds like your lathe is singing the blues, it’s time to take action! Replace pulleys that are too worn out. Remember, an ounce of maintenance is worth a pound of machinery repair!

| Signs of Wear | What to Do |

|---|---|

| Visible cracks | Replace immediately |

| Unusual noises | Inspect and clean |

| Slipping belts | Tighten or replace |

Check your pulleys often, and they will keep spinning smoothly. After all, a happy lathe makes for a happy builder!

Common Issues with Metal Lathe Pulleys and Solutions

Troubleshooting common pulley problems. How to resolve performance issues effectively.Pulleys can cause problems in metal lathes. These issues often affect performance. They may slip, squeak, or wobble. Here are some common troubles and quick fixes:

- Slipping: Check belt tension. Tighten or replace it if needed.

- Squeaking: Apply lubricant to the bearings.

- Wobbling: Ensure pulleys are aligned correctly.

Addressing these problems quickly keeps your lathe running smoothly. Regular checks can prevent major issues. Don’t wait for a breakdown!

What should I do if my lathe pulley is making noise?

**Apply oil or lubricant to the pulley and bearings.** This often fixes noise issues quickly.

How do I know if my pulley is misaligned?

**Check the pulley against the belt.** If it looks off or the belt wears unevenly, it might be misaligned.

Enhancing Performance with Upgraded Pulley Kits

Benefits of upgrading to highperformance pulleys. Recommendations for top brands and models.Upgrading to high-performance pulleys can make a big difference in your machinery. Think of it as giving your lathe an energy drink! With better pulleys, your machine runs smoother and is much more efficient. You’ll see less wear and tear, and your projects will look fantastic. Some top brands to check out include Springfield Pulleys and PowerMax. They’re the superheroes of the pulley world!

| Brand | Model | Benefits |

|---|---|---|

| Springfield Pulleys | Super Smooth 1001 | Reduces friction, enhances speed |

| PowerMax | Turbo Gear 5000 | Increases durability, lowers maintenance |

Frequently Asked Questions About Metal Lathe Pulleys

Addressing common queries and misconceptions. Expert tips for firsttime users.Many people wonder about the mysteries of metal lathe pulleys. One common question is, “How do I choose the right pulley?” The answer is simple: it should match your lathe’s specifications. Just like choosing the right size of shoes! Always check the diameter and belt size.

First-time users often feel lost. Don’t worry; you’re not alone! A helpful tip is to always refer to your manual. It’s like a treasure map but without the pirates! Don’t forget to keep your workspace clean and organized. This helps prevent accidents and makes your projects easier.

| Question | Answer |

|---|---|

| How often should I replace my pulley? | Replace it when you see wear or damage. |

| Can I use any pulley with my lathe? | No, always match it to your lathe model. |

Conclusion

In conclusion, a kit metal lathe pulley is essential for smooth operation. It helps control speed and power. Choosing the right pulley improves your lathe’s performance. If you’re interested, look for kits that fit your lathe model. You can also explore online tutorials to learn installation. Keep experimenting, and you’ll become more skilled in machining!FAQs

Here Are Five Related Questions On The Topic Of Kit Metal Lathe Pulleys:Sure! Please share the five related questions you want me to answer about kit metal lathe pulleys.

Sure! Please ask your question, and I will give you a short answer in simple language.

What Are The Key Advantages Of Using A Pulley System In A Metal Lathe Compared To Direct Drive Configurations?Using a pulley system in a metal lathe has some great benefits. First, it helps you change speeds easily. You can make the lathe spin fast or slow just by moving a belt. Second, it makes the machine safer since it can handle more force without breaking. Lastly, a pulley system can be quieter than direct drives. This means you can work without too much noise!

How Do You Determine The Correct Size And Ratio Of Pulleys For A Specific Metal Lathe Application?To find the right size and ratio of pulleys for a metal lathe, you start by knowing the lathe’s speed needs. You measure the diameter of the pulleys you have. Then, you can use the pulley ratio to change the speed. If you want a faster speed, you need a smaller pulley on the motor and a bigger one on the lathe. Always check the lathe’s manual for specific details!

What Materials Are Commonly Used To Manufacture Pulleys For Metal Lathes, And What Factors Influence Their Selection?Pulleys for metal lathes are often made from strong materials like steel, aluminum, or plastic. These materials are chosen because they are tough and durable. We want pulleys that can handle heavy work without breaking. The choice also depends on things like weight, cost, and how well they can be used with other parts.

How Do You Maintain And Ensure The Longevity Of Pulleys In A Metal Lathe Assembly?To keep pulleys in a metal lathe working well, you should clean them regularly. Dust and dirt can wear them down. You also need to check if they are tight and not loose. Lubricating them with oil helps them move smoothly. Finally, inspect them for any damage and replace them if needed.

What Are Some Common Troubleshooting Tips For Addressing Pulley-Related Issues In A Metal Lathe Setup?If you have problems with pulleys on a metal lathe, check the belts first. Make sure they are tight and not damaged. Look for any weird sounds when the lathe is running. If it shakes, the pulleys might be misaligned. Adjust them until they sit straight.