Have you ever wondered how precise machines like lathes make beautiful metal parts? A metal lathe bench is more than just a workspace; it is where magic happens. But did you know that adjusting a lathe properly can make a huge difference in your work?

Imagine crafting a perfect part, but it doesn’t come out right. Frustrating, right? This is often due to improper lathe adjustments. Just like tuning a musical instrument, small tweaks can create big changes. Getting these adjustments right can turn average work into amazing results.

In this article, we will explore how to fine-tune your lathe for optimal performance. You will learn tips and techniques that can elevate your metalworking skills. So, if you are ready to dive into the world of lathe adjustments, let’s get started!

Essential Lathe Adjustments For Optimal Metal Lathe Bench Performance

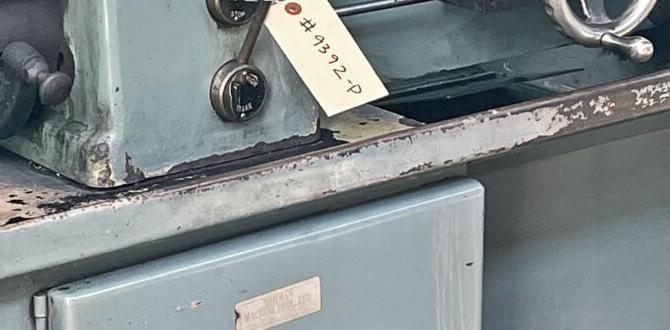

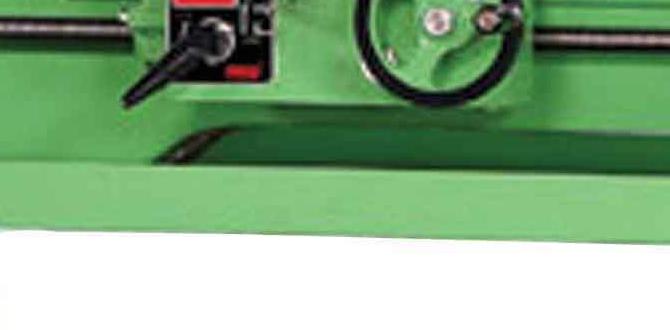

Lathe Adjustments for Metal Lathe Bench

When working with a metal lathe bench, understanding lathe adjustments is crucial. Proper alignment ensures accuracy and quality in machining. Did you know even slight misalignments can ruin a project? Adjust the tailstock and cross slide for precision cuts. Regular maintenance keeps your lathe in top shape and prolongs its life. Explore these adjustments to enhance your skills and make your work shine! Discover the difference small changes can make.Essential Components of a Metal Lathe

Description of key parts that require adjustments (tailstock, carriage, crossslide).. Impact of each component on overall lathe performance..A metal lathe has several key parts that need adjustments for smooth operation. These include the tailstock, carriage, and crossslide. Each component plays a big role in how well the lathe works.

- Tailstock: It holds tools and can be moved for precision.

- Carriage: This part controls the cutting tool position.

- Crossslide: It allows sideways movement for detailed cuts.

When these parts work together well, they help create accurate shapes. Proper lathe adjustments lead to better performance and smoother surfaces.

What do you adjust on a metal lathe?

You mainly adjust the tailstock, carriage, and crossslide to improve accuracy. Making small changes can make a big difference in the finished product!

Basic Lathe Adjustments for Beginners

Stepbystep guide for initial setup and calibration.. Common tools needed for making basic adjustments..Setting up a lathe can be fun and rewarding. Follow these simple steps to get started:

- Check the level of your metal lathe bench.

- Adjust the tailstock for proper alignment.

- Calibrate the carriage and cross-slide for smooth movement.

For these adjustments, you will need:

- Wrenches for tightening screws.

- Calipers for measuring distances.

- A level to check the bench.

These tools help ensure your lathe works like a charm. Happy turning!

What tools can I use for lathe adjustments?

You can use various tools for lathe adjustments. Some common ones are wrenches, calipers, and levels. These tools will help you make precise changes and keep your lathe running smoothly.

Advanced Lathe Adjustments for Precision Machining

Techniques for finetuning alignment and tool positioning.. Importance of leveling the lathe and adjusting the bed..Fine-tuning your lathe can make a big difference. Start with alignment. It ensures the parts fit correctly. Adjust your tool positioning for better cuts. Don’t forget to check your lathe’s level. An uneven lathe can lead to mistakes. Make sure the bed is aligned and smooth. This helps your work shine.

- Check for any wobbling.

- Use tools for precise adjustments.

- Regularly inspect your lathe setup.

Why is leveling important for a lathe?

Leveling keeps the lathe stable. It helps to prevent uneven cuts and extends the life of your machine. A well-leveled lathe makes your projects easier and more accurate.

Troubleshooting Common Lathe Problems

Identification of symptoms caused by poor adjustments.. Solutions for overcoming common lathe issues..When using a lathe, you might notice some issues due to bad adjustments. Common signs include unusual sounds, uneven cuts, or vibrations. To fix these, you can follow some simple solutions:

- Check the alignment of the workpiece.

- Adjust the tool height to match the material.

- Tighten any loose parts or connections.

- Regularly clean and lubricate the lathe.

These tips will help you use your lathe better. Always remember that small changes can make a big difference!

What are common lathe problems?

Common lathe problems include vibration, noise, and uneven cuts. These often happen due to improper adjustments or worn parts, affecting your project quality.

How can I fix lathe issues?

- Inspect all components. Look for any signs of wear or damage.

- Make necessary adjustments. Follow the manufacturer’s guidelines.

- Practice regular maintenance. This keeps your lathe in top shape.

Maintaining Your Metal Lathe for Optimal Performance

Routine maintenance practices to keep lathe adjustments stable.. The role of lubrication and cleanliness in maintaining precision..Keeping your metal lathe in top shape is key to smooth operation. Regular checks and adjustments can be your best friends. Cleanliness is a must! A clean lathe makes for better precision, like a chef with a clean kitchen. Lubrication is also essential—think of it as the lathe’s favorite spa day. A well-oiled machine runs better and lasts longer.

| Maintenance Practice | Why It’s Important |

|---|---|

| Routine Checks | Helps find small issues before they become big problems. |

| Regular Cleaning | Prevents buildup that affects accuracy. |

| Proper Lubrication | Keeps parts moving smoothly for better performance. |

Think of these practices as giving your lathe a daily workout. It truly pays off in the long run!

Safety Precautions During Lathe Adjustments

Essential safety gear and practices to follow.. Common hazards associated with improper adjustments..Using a lathe can be fun, but safety is important. Always wear the right gear. This includes goggles to protect your eyes and earplugs to protect your ears. Here are some safety tips:

- Keep your hair tied back.

- Wear tight clothing.

- Ensure tools are in good shape.

Improper adjustments can lead to common hazards. This includes:

- Flying debris hurtling out.

- Fingers getting caught in the machine.

Stay alert and know how to operate the lathe carefully!

What should I wear for lathe safety?

You should wear safety goggles, ear protection, and tight clothing!Essential gear includes:

- Protective gloves

- Steel-toed shoes

Expert Tips for Mastering Lathe Adjustments

Insights from experienced machinists on optimizing adjustments.. Best practices to develop as a skilled lathe operator..Adjusting a lathe can be tricky, but with the right tips, you can do it well. Experienced machinists suggest focusing on key aspects. For instance, keep your lathe clean and check the level often. Make small adjustments to see how they change your work. Here are some best practices:

- Always double-check measurements.

- Keep tools sharp for better cuts.

- Understand your machine’s manual.

These habits will help you become a skilled lathe operator over time. Remember, practice makes perfect!

What are some tips for adjusting a lathe?

Keep your machine clean, make small adjustments, and always check your measurements. These steps will lead to better results and smoother operation.

Conclusion

In conclusion, understanding lathe adjustments for your metal lathe bench is crucial for accurate work. Regularly check and fine-tune your equipment. This ensures precision and safety. We recommend experimenting with simple adjustments and reading more on the topic. With practice, you’ll become more confident and skilled in using your lathe. Happy turning!FAQs

What Are The Key Adjustments That Can Be Made To Ensure Accurate Machining On A Metal Lathe?To make sure your metal lathe works well, you need to check a few things. First, always align the workpiece correctly in the lathe. This helps it spin evenly. Next, adjust the tool height so it cuts at the right level. We should also make sure the machine is clean and well-lubricated. Finally, keep an eye on the speed to match the material you’re using.

How Often Should A Metal Lathe Be Calibrated And What Tools Are Necessary For Making These Adjustments?You should calibrate a metal lathe regularly, about once a month or every few uses. This helps keep it accurate. To make adjustments, you’ll need tools like a wrench, caliper, and a level. These tools help ensure everything is straight and working well. Always double-check your work to make sure it’s just right!

What Are Some Common Signs That Indicate A Metal Lathe May Need Adjustment Or Alignment?You might notice a metal lathe needs help if it makes strange noises while working. If your machine creates uneven shapes, that’s another sign. You may also see the cutting tool is moving in the wrong way. Plus, if parts aren’t fitting together right, it’s time for an adjustment. Remember to check for these signs regularly!

How Does The Alignment Of The Tailstock And Headstock Affect The Precision Of Workpieces On A Metal Lathe?When we use a metal lathe, the headstock and tailstock need to line up properly. The headstock holds the part that spins, while the tailstock supports the other end. If they aren’t aligned, the piece can wobble or be uneven. This means our work won’t be nice and smooth. Keeping them lined up helps us make better and more precise pieces.

What Steps Should Be Taken To Properly Adjust The Feed Rate And Depth Of Cut On A Metal Lathe For Different Materials?To adjust the feed rate and depth of cut on a metal lathe, start by knowing the material you’re using. Softer materials like aluminum can be cut faster and deeper. For harder materials like steel, you should go slower and lighter. Always check the lathe’s manual for specific suggestions. Finally, make small adjustments and test your cuts to find the best settings.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Adjustments That Can Be Made To Ensure Accurate Machining On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make sure your metal lathe works well, you need to check a few things. First, always align the workpiece correctly in the lathe. This helps it spin evenly. Next, adjust the tool height so it cuts at the right level. We should also make sure the machine is clean and well-lubricated. Finally, keep an eye on the speed to match the material you’re using.”}},{“@type”: “Question”,”name”: “How Often Should A Metal Lathe Be Calibrated And What Tools Are Necessary For Making These Adjustments? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should calibrate a metal lathe regularly, about once a month or every few uses. This helps keep it accurate. To make adjustments, you’ll need tools like a wrench, caliper, and a level. These tools help ensure everything is straight and working well. Always double-check your work to make sure it’s just right!”}},{“@type”: “Question”,”name”: “What Are Some Common Signs That Indicate A Metal Lathe May Need Adjustment Or Alignment? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You might notice a metal lathe needs help if it makes strange noises while working. If your machine creates uneven shapes, that’s another sign. You may also see the cutting tool is moving in the wrong way. Plus, if parts aren’t fitting together right, it’s time for an adjustment. Remember to check for these signs regularly!”}},{“@type”: “Question”,”name”: “How Does The Alignment Of The Tailstock And Headstock Affect The Precision Of Workpieces On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we use a metal lathe, the headstock and tailstock need to line up properly. The headstock holds the part that spins, while the tailstock supports the other end. If they aren’t aligned, the piece can wobble or be uneven. This means our work won’t be nice and smooth. Keeping them lined up helps us make better and more precise pieces.”}},{“@type”: “Question”,”name”: “What Steps Should Be Taken To Properly Adjust The Feed Rate And Depth Of Cut On A Metal Lathe For Different Materials? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the feed rate and depth of cut on a metal lathe, start by knowing the material you’re using. Softer materials like aluminum can be cut faster and deeper. For harder materials like steel, you should go slower and lighter. Always check the lathe’s manual for specific suggestions. Finally, make small adjustments and test your cuts to find the best settings.”}}]}