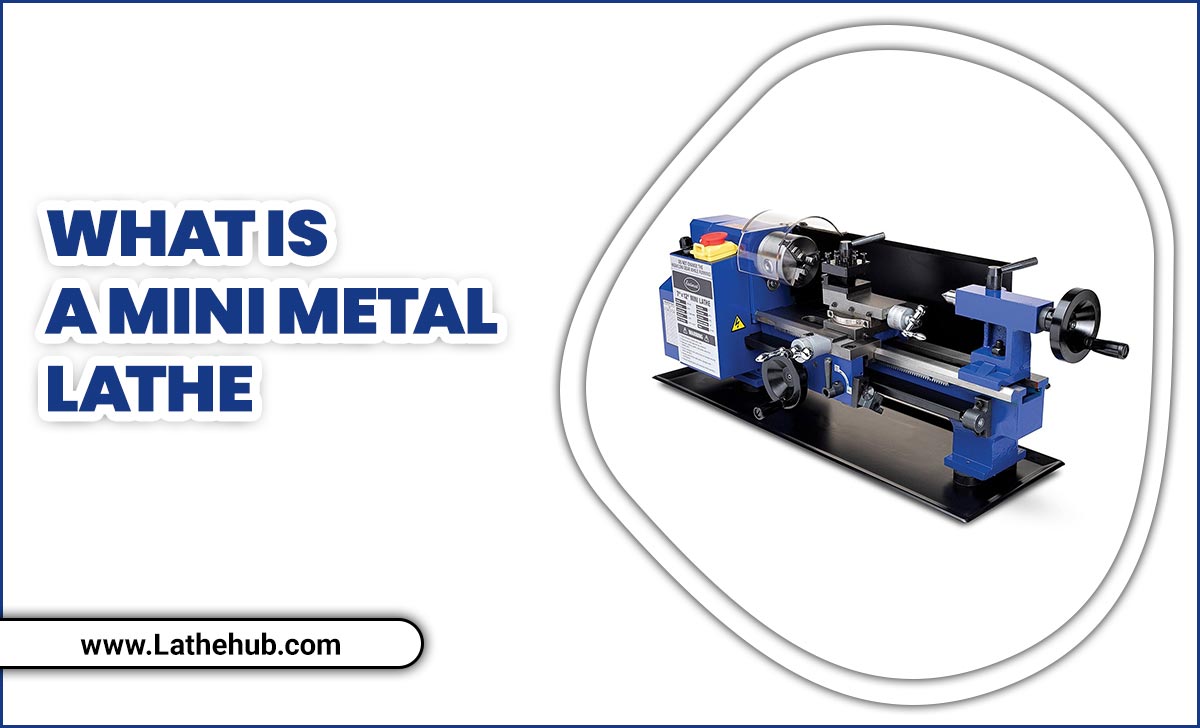

Have you ever wondered how metal parts are made so precisely? One of the secrets lies in lathe adjustments. A metal lathe is a fascinating machine that can shape metal into various forms. The compound rest is a key part of this machine. It allows for precise cuts and shapes in the metal. But, what happens when your cuts are not accurate?

Making tiny adjustments can change everything. Just a slight tweak can transform a rough piece of metal into a finely shaped object. Imagine trying to make a custom part for a project. If your lathe isn’t adjusted correctly, you might end up with a shape that doesn’t fit at all!

In this article, we will dive into the world of lathe adjustments. You will discover how to manage your metal lathe compound rest. You’ll learn tips and tricks to achieve perfect cuts every time. Get ready to unlock the secrets of precise metalworking!

Essential Lathe Adjustments: Optimizing Metal Lathe Compound Rest

Lathe Adjustments: Metal Lathe Compound Rest

Adjusting the compound rest of a metal lathe is key for precise machining. Did you know that a small change can greatly impact your project’s success? You’ll learn how to align the rest properly for accurate cuts. This adjustment helps with angles and threading, making your tasks easier. Remember, a well-adjusted lathe can turn rough materials into perfect shapes. Discover the tricks to keep your projects on track and improve your skills!Understanding the Compound Rest

Definition and purpose of the compound rest in metal lathes. Key components and mechanics involved in its functionality.The compound rest is a crucial part of metal lathes. It helps secure the cutting tool and allows for precise adjustments. Imagine it like a superhero sidekick that helps you shape metal! Key components include the carriage, cross-slide, and tool holder. They work together like a well-rehearsed dance team. The compound rest lets you tilt the cutting tool for angled cuts, making your job easier. Plus, it adds a sprinkle of magic to metalwork!

| Key Component | Function |

|---|---|

| Carriage | Moves the workpiece back and forth. |

| Cross-Slide | Adjusts the tool’s position sideways. |

| Tool Holder | Secures the cutting tool for stability. |

Importance of Lathe Adjustments

How proper adjustments improve precision and accuracy. Impact on overall machining performance and tool longevity.Adjusting a lathe is vital for many reasons. Proper adjustments boost precision and accuracy. This helps create parts that fit perfectly. Better adjustments lead to smoother machining. This means less wear on tools, helping them last longer. Over time, good adjustments can save money by reducing waste.

- Improves part quality

- Reduces tool wear

- Saves time

Why are lathe adjustments important?

Lathe adjustments are crucial for achieving high-quality parts. They help ensure the tools work better and last longer. Properly adjusted lathes can make machines run smoother and faster.

Common Issues with Compound Rest Adjustments

Identifying misalignment problems and their symptoms. Impact of wear and tear on adjustment accuracy.Misalignment can sneak up on your compound rest, leading to some telltale signs. Look out for uneven surfaces or strange noises—it’s like your lathe is trying to tell you a joke! Wear and tear over time can also throw off precision. Components may become loose or stiff, making adjustments harder than finding a sock with no match. Regular checks can keep your lathe’s settings sharp and ready for action!

| Symptom | Possible Issue |

|---|---|

| Uneven cuts | Misalignment |

| Strange noises | Worn-out parts |

| Difficulty in adjustment | Loss of precision |

Step-by-Step Guide to Adjust the Compound Rest

Tools required for adjustments. Detailed steps for adjusting the compound rest to ensure optimal performance.To adjust the compound rest, you’ll need a few simple tools. Gather a wrench, a screwdriver, and a feeler gauge. These tools help you make the right adjustments easily. Follow these steps:

- Loosen the locking screws with the wrench.

- Move the compound rest carefully to align it correctly.

- Use the feeler gauge to check the gap between parts.

- Tighten the locking screws back once aligned properly.

These adjustments ensure that your metal lathe operates smoothly and accurately.

What is the main function of the compound rest?

The compound rest helps position the cutting tool. It allows for precise angle cuts, making it essential for accuracy in metalworking. Adjusting it properly keeps your work efficient and effective.

Tips for Maintaining the Compound Rest

Best practices for regular maintenance to prevent adjustments from going awry. Recommendations on lubrication and cleaning techniques.Keeping the compound rest in shape is easy with a few simple tips. Regularly check for dirt and grime. A clean machine works better! Use oil to lubricate moving parts. This prevents rust and wear. Here are best practices for maintenance:

- Clean with a soft cloth after each use.

- Apply oil to joints and slides every month.

- Inspect for loose screws and tighten them.

These steps help keep your lathe adjustments on track!

How often should I lubricate the compound rest?

Lubricate your compound rest every month to ensure smooth operation and prevent damage.

Troubleshooting Compound Rest Issues

Common problems and their solutions. How to diagnose specific issues effectively.Many people face issues with the compound rest on their lathe. Recognizing these problems helps you fix them quickly. Here are common issues you might see:

- Loose Handles: If the handle feels wobbly, tighten the screws.

- Sticking Movement: Clean the slides. Lubricate them for smooth movement.

- Incorrect Angles: Use a protractor to check angles. Adjust as needed.

To diagnose problems, observe closely. Ask yourself questions. Is something not moving? Does it feel off? Your careful examination can lead to effective solutions.

What are common issues with a compound rest?

Common issues include loose handles, sticking movements, and incorrect angles.

Advanced Techniques for Precision Adjustments

Methods for finetuning your adjustments. Utilizing measuring instruments to enhance accuracy.Perfect adjustments can feel like magic. To be precise, use tools like calipers and micrometers—they’re like the wizards of measurement! You can finely tune your metal lathe by making tiny changes to the compound rest. A tiny twist can change everything, sometimes even your coffee break plans!

Check out this handy table for quick tips:

| Method | Description |

|---|---|

| Calipers | Measure depth and thickness accurately. |

| Micrometers | Great for very small measurements. |

| Tweaking | A little adjustment can lead to big results! |

Remember, every expert was once a beginner, so keep practicing. With time, you’ll make those adjustments like a pro. Just don’t adjust your lunch plans too much!

FAQs About Lathe Adjustments and Compound Rest

Addressing common questions and misconceptions. Providing expert advice and guidance for novice users.People often have questions about lathe adjustments, especially beginners. This tool can be tricky at first. It’s important to understand the compound rest function. Here are some common concerns:

- What is a compound rest? It’s a part that helps you shape your workpiece accurately.

- How do I adjust it? Adjust it by loosening the screws, moving it to the desired angle, and tightening them back.

- Can I use it for different materials? Yes, but settings might change based on the material type.

Don’t hesitate to ask for help. Understanding your lathe will improve your skills over time.

Conclusion

In summary, adjusting the compound rest on a metal lathe is crucial for precision work. You can improve your projects with simple adjustments. Always check the angles and tightness of your settings. Practicing these skills will help you create better designs. For more tips, consider reading expert guides on metal lathe operation. Happy machining!FAQs

Sure! Here Are Five Questions Related To Lathe Adjustments For A Metal Lathe Compound Rest:Sure! Here are five questions about adjusting a metal lathe compound rest: 1. How do you adjust the angle of the compound rest? You turn the handle until it reaches the right angle for cutting. 2. What should you check before making adjustments? Always check that the tool and material are secure and safe. 3. How do you lock the compound rest in place? You tighten the locking handle or screw so it doesn’t move. 4. Why is it important to adjust the compound rest correctly? Correct adjustments help you make precise cuts and shapes. 5. What happens if the rest is not adjusted well? If it’s not right, your work may be uneven or not fit together properly.

Sure! Please provide the question you’d like me to answer.

What Are The Steps To Properly Align The Compound Rest On A Metal Lathe For Accurate Machining?To align the compound rest on a metal lathe, first, clean the surface where it sits. Next, make sure the base is level and tight. Then, adjust the compound rest so it points straight down the lathe’s length. Use a dial gauge to check if it’s straight. Finally, tighten everything down, and you’re ready to machine!

How Do You Adjust The Compound Rest To Achieve Precise Angles For Taper Turning?To adjust the compound rest, first, you find the angle you need. You turn the handle to change the angle on the rest. Make sure it’s tight so it won’t move. Then, you can start your taper turning, checking your work as you go. This helps you make the right shape easily and accurately.

What Common Issues Can Arise From Improper Adjustments Of The Compound Rest On A Metal Lathe, And How Can They Be Resolved?If you adjust the compound rest on a metal lathe wrong, you might have problems. The cuts can be uneven, or you may break tools. These issues can make your projects messy or ruin them. To fix this, double-check your settings and make sure everything is tight and straight. You can also ask someone for help if you’re unsure.

How Often Should The Compound Rest Be Checked And Adjusted For Optimal Performance In Machining Operations?You should check the compound rest at the start of each work session. If you notice any problems while working, adjust it right away. This helps make sure your machine cuts well. Regular checks keep everything running smoothly. Remember, a small adjustment can make a big difference!

What Tools Are Necessary For Making Adjustments To The Compound Rest On A Metal Lathe?To adjust the compound rest on a metal lathe, you need a few tools. First, grab a wrench to loosen the bolts. Next, use a ruler or caliper to check the measurements. A screwdriver will help tighten anything back up. Finally, have a small hammer handy just in case you need to tap things into place.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Lathe Adjustments For A Metal Lathe Compound Rest:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about adjusting a metal lathe compound rest: 1. How do you adjust the angle of the compound rest? You turn the handle until it reaches the right angle for cutting. 2. What should you check before making adjustments? Always check that the tool and material are secure and safe. 3. How do you lock the compound rest in place? You tighten the locking handle or screw so it doesn’t move. 4. Why is it important to adjust the compound rest correctly? Correct adjustments help you make precise cuts and shapes. 5. What happens if the rest is not adjusted well? If it’s not right, your work may be uneven or not fit together properly.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Steps To Properly Align The Compound Rest On A Metal Lathe For Accurate Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align the compound rest on a metal lathe, first, clean the surface where it sits. Next, make sure the base is level and tight. Then, adjust the compound rest so it points straight down the lathe’s length. Use a dial gauge to check if it’s straight. Finally, tighten everything down, and you’re ready to machine!”}},{“@type”: “Question”,”name”: “How Do You Adjust The Compound Rest To Achieve Precise Angles For Taper Turning?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the compound rest, first, you find the angle you need. You turn the handle to change the angle on the rest. Make sure it’s tight so it won’t move. Then, you can start your taper turning, checking your work as you go. This helps you make the right shape easily and accurately.”}},{“@type”: “Question”,”name”: “What Common Issues Can Arise From Improper Adjustments Of The Compound Rest On A Metal Lathe, And How Can They Be Resolved?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you adjust the compound rest on a metal lathe wrong, you might have problems. The cuts can be uneven, or you may break tools. These issues can make your projects messy or ruin them. To fix this, double-check your settings and make sure everything is tight and straight. You can also ask someone for help if you’re unsure.”}},{“@type”: “Question”,”name”: “How Often Should The Compound Rest Be Checked And Adjusted For Optimal Performance In Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check the compound rest at the start of each work session. If you notice any problems while working, adjust it right away. This helps make sure your machine cuts well. Regular checks keep everything running smoothly. Remember, a small adjustment can make a big difference!”}},{“@type”: “Question”,”name”: “What Tools Are Necessary For Making Adjustments To The Compound Rest On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the compound rest on a metal lathe, you need a few tools. First, grab a wrench to loosen the bolts. Next, use a ruler or caliper to check the measurements. A screwdriver will help tighten anything back up. Finally, have a small hammer handy just in case you need to tap things into place.”}}]}