Have you ever wondered how machines shape metal so perfectly? If you’ve seen a lathe in action, you know it’s impressive. But did you know that keeping a lathe in top shape requires regular adjustments?

Understanding lathe adjustments can be tricky. However, it’s key to getting the best results. A metal lathe is not just a tool; it’s a gateway to creativity and precision. For anyone looking to enhance their skills, a wiring diagram can be a handy guide. It helps you visualize the connections and makes adjustments easier.

Let’s dive into how these adjustments work. Imagine working on a project and your lathe starts behaving strangely. Wouldn’t it be great to know how to fix it? By understanding lathe adjustments and wiring, you’ll be ready for anything.

Essential Lathe Adjustments: Metal Lathe Wiring Diagram Guide

Lathe Adjustments and Wiring Diagrams

When working with a metal lathe, making the right adjustments is crucial. Proper setups can improve accuracy and performance. A wiring diagram helps you understand how the electrical components connect. By knowing this, you can troubleshoot issues faster. Imagine being able to fix a problem without calling for help! Learning these adjustments and reading a wiring diagram can turn you into a lathe expert. So, why not dive in and explore?The Importance of Proper Adjustments

Impact of adjustments on machining accuracy. Common pitfalls of improper settings.Proper adjustments are key to successful machining. Imagine trying to bake a cake without measuring—chaos! Adjusting a lathe helps ensure accurate cuts and shapes. When settings are off, even the best materials can become useless. Common mistakes include misalignment and incorrect speeds. These can turn your masterpiece into a lopsided potato. A little tweaking saves time and frustration later on. Remember, a lathe is like a picky cat; it likes things just right!

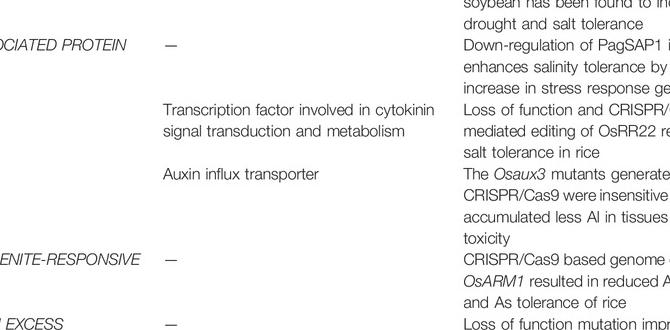

| Adjustment Issue | Impact |

|---|---|

| Misalignment | Leads to uneven cuts. |

| Incorrect Speeds | Can damage materials. |

| Poor Tool Setup | Affects precision. |

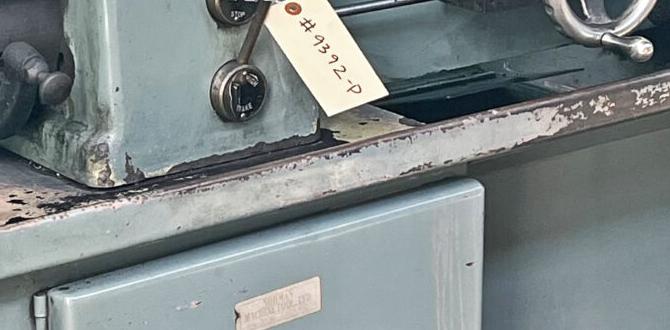

Essential Components of Metal Lathes

Breakdown of key components (e.g., spindle, tailstock, carriage). Functions and adjustments related to each component.Every metal lathe has a few important parts that work together like a well-rehearsed band. First, there’s the spindle. It spins the workpiece and helps shape it. Adjusting the spindle speed can give you smoother finishes. Next up is the tailstock, which supports the other end of the workpiece. You can move it to fit different lengths. Lastly, we have the carriage, which moves the cutting tool back and forth. A well-aligned carriage can make your cuts more accurate! Remember, adjustments are key to keeping everything in harmony!

| Component | Function | Adjustment |

|---|---|---|

| Spindle | Holds and spins the workpiece | Speed adjustment for better finish |

| Tailstock | Supports the workpiece | Move to accommodate length |

| Carriage | Moves the cutting tool | Align for precision cuts |

Common Lathe Adjustments Explained

Types of common adjustments (e.g., bed alignment, spindle alignment). Stepbystep procedures for making these adjustments.Using a lathe can be fun, but getting it right is key! There are common adjustments that help ensure it runs smoothly. First, consider bed alignment. This keeps the bed straight and level. Next, check spindle alignment. A wobbly spindle can make your work look like a roller coaster! Here’s a simple table to help you:

| Adjustment Type | Steps |

|---|---|

| Bed Alignment | 1. Loosen the bed bolts. 2. Adjust the bed. 3. Tighten the bolts. |

| Spindle Alignment | 1. Check the spindle for wobble. 2. Adjust it as needed. 3. Tighten everything. |

With these tips, you’ll be spinning perfect pieces in no time! Remember, a well-adjusted lathe is a happy lathe!

Lathe Wiring Diagrams: An Essential Guide

Explanation of wiring components and their functions. Importance of understanding wiring diagrams for troubleshooting.Understanding the wiring components of your lathe is key to its success. These parts include switches, motors, and power supplies. Each one plays a unique role in keeping the machine running smoothly. Knowing how to read wiring diagrams helps you troubleshoot problems effectively. That way, you can fix issues faster and keep your lathe in top shape. A well-maintained lathe can last longer and work better.

What are the main components of lathe wiring?

- Switches: Control power to the lathe.

- Motors: Drive the lathe’s movement.

- Power Supply: Provides energy for operation.

Why is understanding wiring diagrams important?

Knowing how to read wiring diagrams helps with troubleshooting. You can quickly find faults and make repairs. This skill can save you time and money.

How to Read a Lathe Wiring Diagram

Key symbols and terminology in wiring diagrams. Stepbystep guide to interpreting a wiring diagram.Reading a lathe wiring diagram can seem tricky at first. But with a little practice, it becomes easy. First, understand the key symbols. Look for lines, circles, and letters. Each symbol has a meaning. Next, follow these steps to interpret the diagram:

- Identify the power source.

- Trace the connections from the source.

- Check switches and controls.

- Note any components like motors and sensors.

- Follow the path to see how everything links together.

Learning these symbols helps you work safely. It’s like a treasure map for your lathe!

What do symbols in a wiring diagram mean?

Common symbols show power sources, connections, and signals. For example, a circle often means a connection point. Understanding these helps you fix issues quickly.

Troubleshooting Common Lathe Issues

Identification of common problems related to adjustments and wiring. Solutions and tips for effective troubleshooting.Troubleshooting a lathe doesn’t have to be as tricky as it sounds. Common issues include strange noises, the machine not turning on, or uneven cuts. First, check the adjustments. A loose part can cause chaos—like trying to dance in a poorly-fitted pair of shoes! Next, inspect the wiring. If wires are frayed or disconnected, that’s a clear sign for action. Don’t panic! Most problems have easy fixes. Remember, safety first: always unplug the machine before you start tinkering! Here’s a quick table to help you out:

| Issue | Possible Cause | Solution |

|---|---|---|

| Machine won’t start | Power supply issue | Check the plug and outlet |

| Strange noises | Loose parts | Tighten all screws |

| Uneven cuts | Improper settings | Re-adjust the tool height |

With these tips, you’ll be back to making beautiful pieces in no time. And remember, every expert was once a beginner—so be patient with yourself!

Best Practices for Lathe Maintenance

Routine checks and adjustment recommendations. Longterm maintenance tips to enhance performance.To keep your lathe running smoothly, regular checks are key. Check the belts, gears, and alignments at least once a month. Clean out any dust from the components. For long-term care, follow these steps:

- Oiling moving parts every few weeks helps in smooth operation.

- Inspect electrical connections to prevent weak wiring.

- Store your lathe in a dry place to avoid rust.

These simple tasks can boost performance and extend your lathe’s life!

How can I maintain my lathe effectively?

Regular cleaning and lubrication are essential for good lathe maintenance. Keep checking for wear and tear on parts to stay ahead of issues.

Resources for Further Learning

Recommended books and online courses. Forums and communities for lathe enthusiasts.Learning about lathes can be fun and exciting! You can read books that teach you about lathe operations and adjustments. Online courses are also great for hands-on lessons. Don’t forget to join forums for tips and tricks from other lathe fans. These places can help you grow your skills. Here are some good resources:

- Books on lathe techniques

- Online courses on metalworking

- Forums for sharing ideas

Frequently Asked Questions

Common queries related to lathe adjustments and wiring. Expert answers to enhance understanding and troubleshoot issues.Many people have questions about lathe adjustments and wiring. Here are some common queries and simple answers.

What are common lathe adjustment issues?

Common issues include vibration, noise, and incorrect cuts. Make sure the lathe is leveled and all parts are tightly secured. Regular maintenance helps too.

How do I wire a metal lathe?

Wiring a metal lathe requires following specific diagrams. Check your wiring diagram carefully to match the correct connections. This helps in avoiding any damage or malfunction.

Key Tips for Wiring:

- Use the right tools.

- Follow the manufacturer’s instructions.

- Double-check connections before power.

Understanding these basics can make your lathe experience safer and more efficient.

Conclusion

In summary, understanding lathe adjustments and wiring diagrams is essential for effective metalworking. You can enhance your skills by learning how to adjust your lathe properly. Familiarizing yourself with wiring diagrams will keep your equipment running smoothly. Explore tutorials online to improve your knowledge further. Practice these tips and watch your metalworking projects thrive!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Adjustments And Wiring Diagrams For Metal Lathes:A lathe is a machine that helps us shape metal. To make it work well, you might need to make some adjustments. This means changing settings or parts to get the best results. Wiring diagrams show how to connect the electrical parts safely. Following these diagrams helps prevent mistakes.

Sure! Please provide the question you want me to answer.

What Are The Essential Adjustments Needed For Optimal Performance On A Metal Lathe?To get the best performance from a metal lathe, you need to make a few important adjustments. First, check that the cutting tool is sharp and positioned properly. Next, adjust the speed of the lathe to fit the material you’re using. Lastly, make sure the workpiece is secure and straight. These steps help you create smoother cuts and better shapes.

How Can I Interpret A Wiring Diagram For A Metal Lathe To Troubleshoot Electrical Issues?To read a wiring diagram, first identify the parts and symbols. Look for lines connecting these parts; they show how electricity flows. Follow the paths from the power source to see which wires connect to each part. If something isn’t working, check the wires for breaks or loose connections. By tracing the diagram, you can find the problem more easily.

What Safety Precautions Should I Consider When Adjusting A Metal Lathe’S Components?When you adjust a metal lathe, always wear safety glasses to protect your eyes. Keep your hair tied back and wear tight-fitting clothing. Make sure the machine is turned off and unplugged before touching it. Use tools instead of your hands to make adjustments. Finally, never rush; take your time to stay safe.

How Do I Ensure Proper Alignment And Calibration Of The Lathe After Making Mechanical Adjustments?To ensure your lathe is aligned correctly, check the tailstock and headstock are straight. Use a ruler or measuring tool to see if they line up. Then, test the lathe by running a piece of wood through it. If it cuts evenly, you did it right! If not, adjust and check again.

What Common Wiring Issues Might Arise In A Metal Lathe, And How Can I Diagnose And Fix Them?In a metal lathe, wires can get loose or damaged. You might notice that the machine won’t turn on or works erratically. To check, first, make sure the lathe is unplugged. Then, look for any loose or broken wires and reconnect or replace them. Always ask an adult for help if you’re unsure!