Do you ever wonder how to make your metal lathe work perfectly? Aligning your lathe can seem tricky at first. But with the right lathe alignment tips, you can master it quickly. Imagine creating parts that fit together seamlessly. That’s the magic of good alignment!

Many people might not realize how important the setup is. A well-aligned lathe can change everything in your CAD design. It can help you save time and avoid costly mistakes. Who wouldn’t want to make their projects easier?

Here’s a fun fact: did you know that even slight misalignments can lead to big problems? A few millimeters off can ruin a piece! With simple steps, you can keep your metal lathe in top shape.

Ready to dive into the world of lathe alignment? Follow along as we share tips that will boost your confidence. In no time, you’ll be making perfect cuts and designing with ease!

Essential Lathe Alignment Tips For Metal Lathe Cad Design

Lathe Alignment Tips for Metal Lathe CAD Design

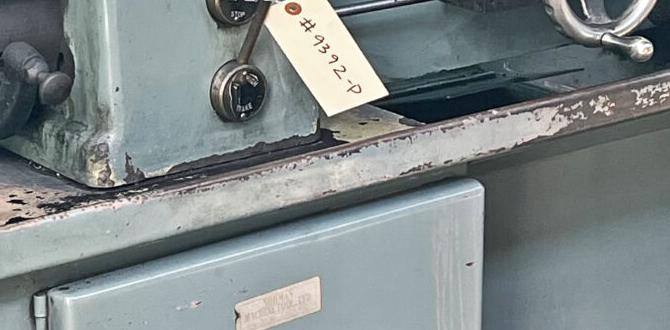

Aligning your metal lathe is crucial for precision work. Did you know that a small misalignment can ruin your project? Proper alignment prevents errors and saves time. Start by checking your lathe bed for levelness. Ensure your tailstock and headstock are aligned accurately. Using CAD design can help visualize adjustments. This way, you can fine-tune alignment before starting work. With these tips, you’ll improve your machining and achieve better results!Understanding Lathe Alignment

Definition and importance of lathe alignment in machining.. Common issues arising from poor alignment..Lathe alignment is all about making sure your metal lathe is set up correctly. Good alignment helps produce smooth and accurate cuts. When your lathe is not aligned, you might face problems like uneven cuts or parts wearing out too quickly. These issues can lead to wasted materials and time. Imagine trying to cut a cake with a wobbly knife—messy!

| Common Issues from Poor Alignment | Effects |

|---|---|

| Uneven Cuts | Inaccurate workpieces |

| Excessive Vibration | Wear and tear on tools |

| Tool Damage | Increased costs and frustration |

By checking and adjusting your lathe regularly, you can avoid these problems! Keep your machine happy, and it will keep you happy too. After all, nobody likes a cranky lathe!

Step-by-Step Lathe Alignment Process

Detailed procedures for aligning a metal lathe accurately.. Importance of checking leveling and trueness in the setup..Aligning a metal lathe is essential for precise work. Start by making sure the lathe is level. Use a spirit level to check if it sits flat on the floor. Next, check for trueness. This means making sure the spindle is perfectly straight. Here are the steps:

- Place a level on the bed of the lathe.

- Adjust the feet until it is perfectly level.

- Use a dial indicator to check the spindle’s trueness.

- Make needed adjustments to align the spindle.

This careful setup leads to better results in your projects.

Why is lathe alignment important?

Lathe alignment is crucial for accurate cutting and smooth operation.Common Lathe Alignment Techniques

Explanation of different techniques such as colinear alignment and threepoint alignment.. Pros and cons of each alignment technique..Several techniques help align a lathe correctly. One way is colinear alignment. This method ensures that the spindle and tailstock are in a straight line. It is simple but can be tricky if used on uneven surfaces.

Another option is three-point alignment. This method uses three points to stabilize the lathe. It gives a more solid setup but takes more time to set up compared to colinear alignment.

Here are some pros and cons of each technique:

- Colinear Alignment:

- Pros: Quick and easy to do.

- Cons: May not work well on uneven surfaces.

- Three-Point Alignment:

- Pros: More stable and reliable.

- Cons: Takes longer to set up.

What are common alignment methods for lathes?

Common methods include colinear and three-point alignment. Each has its own advantages and drawbacks, impacting setup time and stability.Impact of Lathe Misalignment on CAD Design

How misalignment affects design accuracy and machining efficiency.. Examples of design flaws caused by improper alignment..Lathe misalignment can cause big problems in CAD design. It affects how accurately parts fit together. If the lathe is not aligned, the machine cuts unevenly. This can lead to:

- Wobbly edges

- Incorrect dimensions

- Weak joints

For example, if a part should be 2 inches, but it measures 2.5 inches due to misalignment, it won’t fit. Good alignment is key for smooth work and strong results.

How does misalignment affect design accuracy?

Misalignment can create serious flaws in design, leading to wasted materials and extra costs.Examples of flaws include:

- Parts not fitting together

- Uneven surfaces that need rework

- Increased wear and tear on machines

Maintenance Tips for Keeping Alignment in Check

Routine checks and maintenance practices to ensure continued alignment.. Recommended schedules for alignment adjustments..Keeping your metal lathe aligned is like brushing your teeth; skip it, and you’ll regret it later! Regular checks can save you from big headaches—like misaligned cuts! Aim to inspect your lathe every month. Check the bed for flatness and ensure the tailstock aligns perfectly with the spindle.

| Maintenance Task | Recommended Schedule |

|---|---|

| Inspect bed level | Monthly |

| Check spindle alignment | Every 3 months |

| Adjust tailstock | As needed |

Following these tips will keep your lathe running smoother than a well-oiled machine. Plus, you don’t want to create new “art” with uneven cuts! Stay sharp, and don’t let misalignment take a toll on your projects.

Case Studies of Successful Lathe Alignment

Examples of industries that benefited from improved lathe alignment.. Lessons learned from case studies that can be applied to CAD design..Many industries have seen amazing changes from better lathe alignment. For example, the automotive industry fixed many machines, saving millions on repairs. The lesson is simple: proper alignment leads to smoother operations. In the woodworking field, companies found that aligned machines made cleaner cuts and less waste. A happy shop means happy wood pieces! Plus, applying these lessons to CAD design can streamline the process and reduce mistakes. Here’s a quick look at some case studies:

| Industry | Benefits | Lessons Learned |

|---|---|---|

| Automotive | Reduced costs by 15% | Align engines for better assembly |

| Woodworking | Fewer errors, less waste | Machine alignment equals cleaner cuts |

| Manufacturing | Boosted production speed 20% | Use precise measurements in design |

Additional Resources and Tools

Recommendations for further reading and tools that aid in lathe alignment.. Online forums and communities for sharing tips and experiences on lathe alignment..If you want to learn more about lathe alignment, explore these resources:

- Books on metalworking and lathe setup provide detailed insights.

- Online courses teach hands-on skills and best practices.

- Videos on platforms like YouTube show practical examples.

Connecting with others can also help you improve. Join online forums to share your tips and ask questions. Some great places to connect include:

- Reddit’s metalworking community

- Facebook groups focused on machining

- Specialized websites like CNC Zone

Sharing your experiences can lead to valuable advice.

What are some good resources for lathe alignment?

You can check out books, online courses, and forums. Connecting with experienced users can help you a lot.

Conclusion

In summary, properly aligning your metal lathe is crucial for accuracy and quality. Use tools like a dial indicator for best results. Always double-check your setup before starting a project. For a clearer understanding, consider exploring CAD design resources. By following these tips, you’ll improve your lathe skills and create better workpieces. Let’s get to crafting!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Alignment Tips For Metal Lathes And Cad Design:Sure! Here are some tips for aligning metal lathes. First, make sure your lathe is on a flat, strong surface. You can use a level tool to check if it’s even. Next, adjust the tailstock and headstock so they are lined up straight. After that, test it by running a piece of metal. If it doesn’t spin evenly, adjust again until it does! Always remember to be careful and use safety gear when working.

Sure! Just let me know the question you’d like me to answer, and I’ll be happy to help!

What Are The Key Steps To Achieve Accurate Alignment Of A Metal Lathe During Setup?To set up a metal lathe correctly, first, make sure the lathe is level. You can use a level tool for this. Next, check that the spindle, which spins the metal, is straight and lined up. Adjust the tailstock so it is also aligned with the spindle. Finally, double-check everything to make sure it’s just right before you start working.

How Can Cad Design Software Be Utilized To Improve The Alignment Process Of A Metal Lathe?We can use CAD (Computer-Aided Design) software to help with the alignment of a metal lathe. First, we can create a 3D model of the lathe. This model shows exactly how parts should fit together. Next, we can check if everything is perfectly aligned before we start working. This way, we avoid mistakes and make sure our projects are done right!

What Tools Are Essential For Checking And Maintaining Lathe Alignment In A Metalworking Environment?To check and keep a lathe aligned, you need a few important tools. A dial indicator helps measure tiny movements. A straightedge helps you see if the lathe is straight. You might also use a level to check if it’s balanced. These tools help ensure the lathe works well and makes good parts!

How Does Improper Alignment Affect The Machining Process And The Final Quality Of The Workpiece?Improper alignment means the machine parts aren’t lined up right. This can cause cutting tools to move unevenly. When this happens, you can get rough edges or wrong shapes on the workpiece. It makes your final piece less accurate and not as nice. So, always check that everything is aligned correctly!

What Are Some Common Alignment Issues That Can Arise With Metal Lathes, And How Can They Be Resolved?Metal lathes can have alignment problems like the bed being uneven or the tailstock not lining up. To fix these, you can adjust the legs of the lathe or move the tailstock into the right spot. We can also check the parts to make sure they are tight and straight. Keeping everything clean helps too. Regularly checking your lathe will help it work better!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Alignment Tips For Metal Lathes And Cad Design:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some tips for aligning metal lathes. First, make sure your lathe is on a flat, strong surface. You can use a level tool to check if it’s even. Next, adjust the tailstock and headstock so they are lined up straight. After that, test it by running a piece of metal. If it doesn’t spin evenly, adjust again until it does! Always remember to be careful and use safety gear when working.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know the question you’d like me to answer, and I’ll be happy to help!”}},{“@type”: “Question”,”name”: “What Are The Key Steps To Achieve Accurate Alignment Of A Metal Lathe During Setup?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe correctly, first, make sure the lathe is level. You can use a level tool for this. Next, check that the spindle, which spins the metal, is straight and lined up. Adjust the tailstock so it is also aligned with the spindle. Finally, double-check everything to make sure it’s just right before you start working.”}},{“@type”: “Question”,”name”: “How Can Cad Design Software Be Utilized To Improve The Alignment Process Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use CAD (Computer-Aided Design) software to help with the alignment of a metal lathe. First, we can create a 3D model of the lathe. This model shows exactly how parts should fit together. Next, we can check if everything is perfectly aligned before we start working. This way, we avoid mistakes and make sure our projects are done right!”}},{“@type”: “Question”,”name”: “What Tools Are Essential For Checking And Maintaining Lathe Alignment In A Metalworking Environment?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check and keep a lathe aligned, you need a few important tools. A dial indicator helps measure tiny movements. A straightedge helps you see if the lathe is straight. You might also use a level to check if it’s balanced. These tools help ensure the lathe works well and makes good parts!”}},{“@type”: “Question”,”name”: “How Does Improper Alignment Affect The Machining Process And The Final Quality Of The Workpiece?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Improper alignment means the machine parts aren’t lined up right. This can cause cutting tools to move unevenly. When this happens, you can get rough edges or wrong shapes on the workpiece. It makes your final piece less accurate and not as nice. So, always check that everything is aligned correctly!”}},{“@type”: “Question”,”name”: “What Are Some Common Alignment Issues That Can Arise With Metal Lathes, And How Can They Be Resolved?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes can have alignment problems like the bed being uneven or the tailstock not lining up. To fix these, you can adjust the legs of the lathe or move the tailstock into the right spot. We can also check the parts to make sure they are tight and straight. Keeping everything clean helps too. Regularly checking your lathe will help it work better!”}}]}