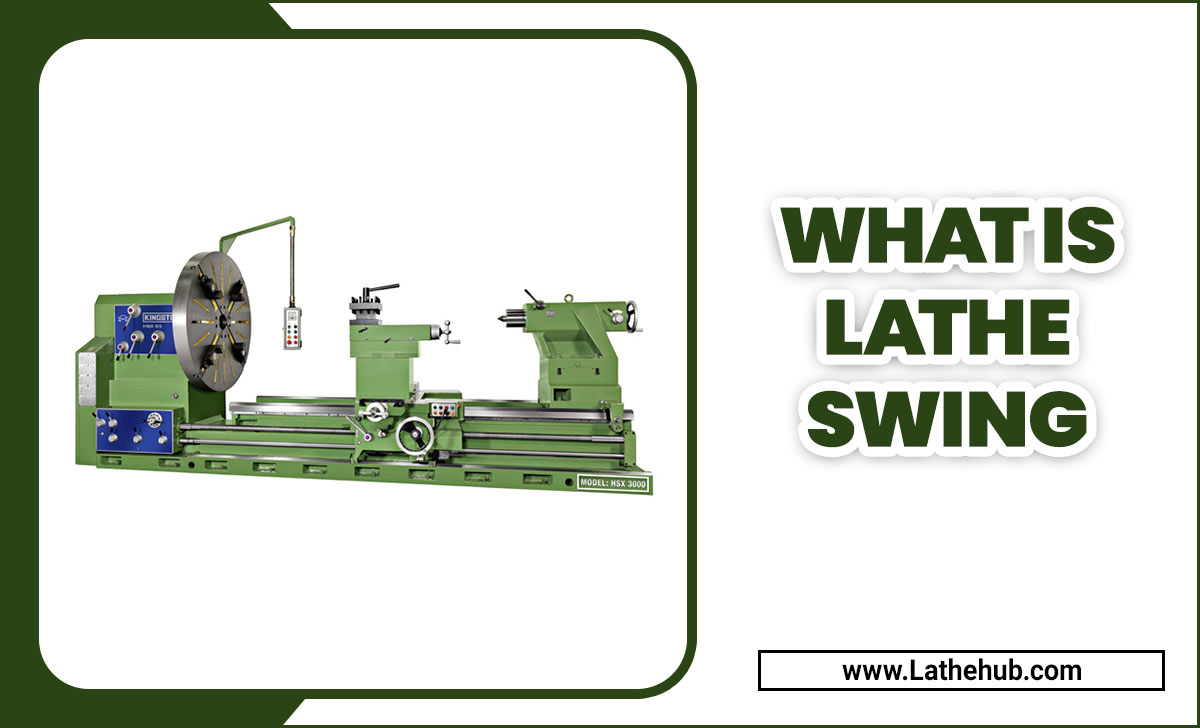

Have you ever wondered how to make your metal lathe work better? Proper lathe alignment plays a critical role in your projects. If your lathe isn’t aligned well, it can ruin your work and waste your time.

Imagine trying to cut a straight line, but your machine keeps pulling to one side. Frustrating, right? Many people struggle with getting their metal lathe just right. That’s where lathe alignment tips come in. These tips can help you improve accuracy and save effort.

One key to smooth operation is using the power feed correctly. But how do you do that? Understanding these simple tricks can make a big difference. You will find the process easier, and your results will amaze you!

Let’s explore some great lathe alignment tips. Soon, you’ll be machining like a pro.

Lathe Alignment Tips For Metal Lathe Power Feed Success

Essential Lathe Alignment Tips for Metal Lathe Power Feed

Are you struggling with your metal lathe’s precision? Proper lathe alignment is key. Start by checking the bed level. A simple level tool can prevent common issues. Next, ensure the tailstock aligns correctly. Misalignment can cause uneven cuts. Consider adjusting the power feed speed for smoother operation. This helps in maintaining better control over your work. Did you know that even a tiny misalignment can lead to big mistakes in your projects? Small efforts in alignment can lead to excellent results!Understanding Lathe Alignment

Importance of proper lathe alignment for precision machining. Common issues resulting from misalignment.Proper lathe alignment is crucial for making precise parts. Without it, your machining might go wrong. Misalignment can lead to issues like uneven cuts and wasted materials. It can also cause parts to wear out faster.

- Poor surface finish

- Increased tool wear

- Inaccurate measurements

Taking time to align your lathe correctly can prevent these problems. It saves time and money, helping you work smarter.

Why is proper lathe alignment important?

Proper lathe alignment ensures accuracy in every part you create, helping to avoid costly repairs and rework.

Tools Required for Lathe Alignment

Essential tools for measuring alignment. Recommended accessories for improving accuracy.To align your lathe well, you’ll need some important tools. These tools will help you measure the alignment accurately. Here are some essential items:

- Level: A good level helps ensure your lathe is even.

- Taper Gauge: This checks if the machine is straight.

- Dial Indicator: It shows tiny changes in distance.

- Square: A square tool makes sure angles are correct.

- Feeler Gauges: These measure small gaps easily.

Using quality accessories can improve your lathe’s performance. For example, a power feed upgrade can make cuts smoother and more precise.

What tools are essential for lathe alignment?

Essential tools include a level, taper gauge, dial indicator, square, and feeler gauges, as they help you check the alignment correctly.

Step-by-Step Lathe Alignment Process

Detailed instructions on aligning the tailstock and headstock. Techniques for checking and adjusting the ways.Aligning the tailstock and headstock is like giving your lathe a best friend makeover. First, check the distance between the centers of both parts. A feeler gauge works wonders here. Next, adjust the tailstock until it matches the headstock perfectly. Remember, even a little misalignment can lead to wobbly results, like trying to walk in two left shoes! Once aligned, check the ways. Use a straightedge or a level to ensure they are even. Adjust as needed.

| Step | Description |

|---|---|

| 1 | Measure the distance between centers with a feeler gauge. |

| 2 | Adjust the tailstock to align with the headstock. |

| 3 | Check the ways with a straightedge for evenness. |

Common Lathe Alignment Problems and Solutions

Identifying symptoms of misalignment. Troubleshooting strategies for common alignment issues.When a lathe is not aligned correctly, it can cause problems. You may notice uneven cuts or strange sounds. These signs show misalignment. Fixing these issues is crucial for smooth operation.

Here are some tips for troubleshooting:

- Check all bolts and screws. Loose parts can lead to misalignment.

- Inspect the tailstock and headstock. They should be straight.

- Use a dial indicator to measure alignment. It provides accurate readings.

Regular checks and adjustments can keep your lathe running well. Don’t ignore the signs of misalignment!

What are some common lathe alignment problems?

Common lathe alignment problems include unsteady workpiece, vibration during operation, and poor surface finish. These issues often arise from misaligned parts.

Maintaining Lathe Alignment Over Time

Routine checks to ensure continued accuracy. Best practices for maintaining lathe components.Keeping your lathe in tip-top shape doesn’t need to be a secret mission! Regular checks are essential for smooth operations. Check the alignment every few weeks to avoid surprises. Tight nuts and clean parts help too. Dust bunnies love to snuggle up on your machine, but they don’t help with accuracy. Remember, an unhappy lathe can turn your projects into “unique” shapes!

| Task | Frequency | Purpose |

|---|---|---|

| Check alignment | Every 2 weeks | Ensure accuracy |

| Clean components | Weekly | Prevent wear |

| Inspect belts | Monthly | Avoid slippage |

By staying on top of these small tasks, your lathe will work hard and avoid giving you a headache with unexpected hiccups!

Benefits of Proper Lathe Alignment

Impact on product quality and dimensional accuracy. Cost savings and efficiency improvements in production.Proper lathe alignment offers many benefits. First, it greatly improves product quality and dimensional accuracy. This means your parts fit better and work as they should. Second, it saves money and boosts the speed of production. Less wasted material means lower costs. Here are some key points:

- Better fit and finish

- Fewer do-overs

- Reduced machine wear

In short, good alignment keeps everything running smoothly and makes your work easier.

How does lathe alignment affect production costs?

Proper lathe alignment can cut production costs by reducing waste and mistakes. This saves money and time.

Leveraging Power Feed for Enhanced Alignment

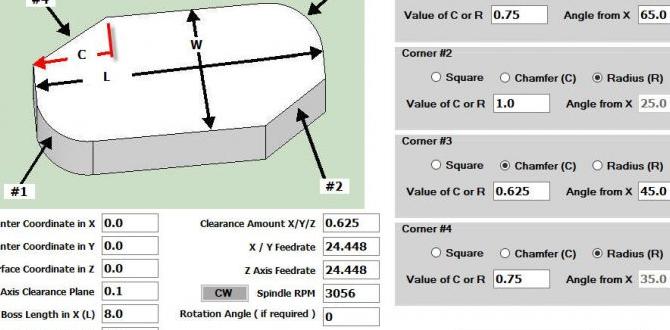

Advantages of using power feed in alignment processes. Tips for optimizing power feed settings for better alignment.Using power feed can make alignment easier and more accurate. Here are some benefits:

- Consistent Speed: Power feed helps maintain a steady speed during cutting.

- Less Operator Fatigue: It reduces hand strain and lets you focus on the task.

- Improved Precision: It keeps the tool steady, leading to better results.

To optimize power feed settings:

- Start with the manufacturer’s recommended speed.

- Adjust based on the material being cut.

- Check for even wear on the tool.

These tips can enhance your alignment process and help you create better projects.

What are the benefits of using power feed in alignment?

Power feed improves speed and accuracy, reduces fatigue, and ensures consistent results.

Expert Tips from Professional Machinists

Insights and recommendations from experienced users. Realworld examples of successful alignment practices.Learning from the best can help you align your metal lathe better. Experienced machinists suggest these tips:

- Always check your machine level before use.

- Make small adjustments to achieve a perfect alignment.

- Use a dial indicator for accuracy.

- Regularly clean and maintain your lathe.

For instance, one user aligned their lathe with simple tools and improved their output by 30%. Such real-world successes show the value of following expert advice. Are you ready to enhance your skills?

What are some easy alignment tips?

Some easy tips include leveling your lathe, using a dial indicator, and keeping your lathe clean. Regular maintenance helps ensure better performance and longer life for your equipment.

Conclusion

In conclusion, proper lathe alignment is crucial for smooth operation and accurate cuts. Remember to check your spindle alignment and adjust it as needed. Using the power feed correctly can boost efficiency. For the best results, practice these tips regularly. You might also explore more resources to sharpen your skills. Happy turning!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Alignment Tips For Metal Lathe Power Feed:Sure! Here are five related questions about lathe alignment tips for metal lathe power feed. 1. Why is lathe alignment important? Lathe alignment helps the machine work better. It makes sure we cut things straight and even. 2. How do I check if my lathe is aligned? You can use a level or a straightedge. Place it on the lathe bed and see if it’s straight. 3. What should I do if my lathe is not aligned? If it’s not aligned, you can adjust the feet or screws. This helps make it level and straight again. 4. How often should I check lathe alignment? You should check it whenever you set up your lathe. It’s good to check every few months too. 5. Can poor alignment damage my lathe? Yes, poor alignment can hurt the lathe and the tools. It’s important to keep it aligned to avoid problems.

Sure! Just let me know what question you would like me to answer, and I’ll be happy to help!

What Are The Key Indicators That A Metal Lathe Is Misaligned, And How Can I Check For Them?If a metal lathe is misaligned, you might notice uneven cuts or a wobbly piece of metal. You can check this by measuring the distance from the tool to the workpiece. Use a ruler to see if this distance is the same all around. If it isn’t, the lathe may need to be adjusted. You can also watch if the tool moves smoothly; if it shakes, that’s another sign of misalignment.

How Can I Properly Align The Tailstock And Headstock To Ensure Accurate Machining With The Power Feed?To align the tailstock and headstock, start by checking if both parts are straight. Use a ruler or a straight edge to look for gaps. Adjust the tailstock until it lines up perfectly with the headstock. Finally, test it by running the machine with a piece of wood. This way, you’ll get accurate results every time!

What Tools And Techniques Are Recommended For Precise Alignment Of A Metal Lathe During Setup?To set up a metal lathe properly, we can use a level to check if it’s straight. A dial indicator helps measure small distances accurately. You might also use a ruler to check the positions. Always adjust the legs of the lathe to make it stable. This way, you’ll get the best results when working!

How Often Should I Perform Alignment Checks On My Metal Lathe To Maintain Optimal Performance With The Power Feed?You should perform alignment checks on your metal lathe every few months. If you notice any problems, check it sooner. Regular checks help keep everything working well. Always make sure the power feed is aligned correctly. This way, your projects will come out better!

What Are The Common Alignment Issues That Can Affect The Power Feed Operation, And How Can I Troubleshoot Them?Common alignment issues in power feed can happen when parts don’t line up. You might notice strange noises or wobbling. To fix this, first, check if everything is tight and in its place. If something looks bent or off, gently adjust or replace it. Lastly, test the power feed to see if it runs better.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Alignment Tips For Metal Lathe Power Feed:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five related questions about lathe alignment tips for metal lathe power feed. 1. Why is lathe alignment important? Lathe alignment helps the machine work better. It makes sure we cut things straight and even. 2. How do I check if my lathe is aligned? You can use a level or a straightedge. Place it on the lathe bed and see if it’s straight. 3. What should I do if my lathe is not aligned? If it’s not aligned, you can adjust the feet or screws. This helps make it level and straight again. 4. How often should I check lathe alignment? You should check it whenever you set up your lathe. It’s good to check every few months too. 5. Can poor alignment damage my lathe? Yes, poor alignment can hurt the lathe and the tools. It’s important to keep it aligned to avoid problems.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know what question you would like me to answer, and I’ll be happy to help!”}},{“@type”: “Question”,”name”: “What Are The Key Indicators That A Metal Lathe Is Misaligned, And How Can I Check For Them?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If a metal lathe is misaligned, you might notice uneven cuts or a wobbly piece of metal. You can check this by measuring the distance from the tool to the workpiece. Use a ruler to see if this distance is the same all around. If it isn’t, the lathe may need to be adjusted. You can also watch if the tool moves smoothly; if it shakes, that’s another sign of misalignment.”}},{“@type”: “Question”,”name”: “How Can I Properly Align The Tailstock And Headstock To Ensure Accurate Machining With The Power Feed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align the tailstock and headstock, start by checking if both parts are straight. Use a ruler or a straight edge to look for gaps. Adjust the tailstock until it lines up perfectly with the headstock. Finally, test it by running the machine with a piece of wood. This way, you’ll get accurate results every time!”}},{“@type”: “Question”,”name”: “What Tools And Techniques Are Recommended For Precise Alignment Of A Metal Lathe During Setup?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe properly, we can use a level to check if it’s straight. A dial indicator helps measure small distances accurately. You might also use a ruler to check the positions. Always adjust the legs of the lathe to make it stable. This way, you’ll get the best results when working!”}},{“@type”: “Question”,”name”: “How Often Should I Perform Alignment Checks On My Metal Lathe To Maintain Optimal Performance With The Power Feed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should perform alignment checks on your metal lathe every few months. If you notice any problems, check it sooner. Regular checks help keep everything working well. Always make sure the power feed is aligned correctly. This way, your projects will come out better!”}},{“@type”: “Question”,”name”: “What Are The Common Alignment Issues That Can Affect The Power Feed Operation, And How Can I Troubleshoot Them?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common alignment issues in power feed can happen when parts don’t line up. You might notice strange noises or wobbling. To fix this, first, check if everything is tight and in its place. If something looks bent or off, gently adjust or replace it. Lastly, test the power feed to see if it runs better.”}}]}