Have you ever wondered how to get the most out of your metal lathe? Lathe alignment is key to perfect results. Properly aligning your lathe can make a huge difference in your projects.

Imagine trying to carve a perfect piece, but it keeps coming out crooked. Frustrating, right? That’s why lathe alignment tips are so important! They help keep your work straight and true.

Did you know that the quill on your metal lathe plays a big role in this? If it’s not aligned correctly, it can affect your entire setup. Whether you’re a beginner or an experienced machinist, knowing these tips can save you time and headaches.

In this article, we will explore easy and effective lathe alignment tips. You’ll learn how a few simple adjustments can improve your metal lathe’s performance. Get ready to make your projects easier and more fun!

Lathe Alignment Tips: Essential For Metal Lathe Quill Setup

Lathe Alignment Tips for Metal Lathe Quill

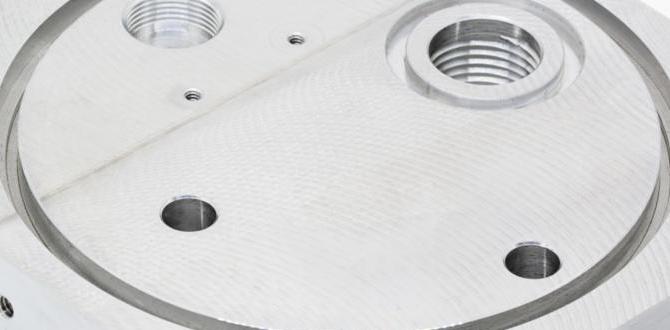

Making sure your metal lathe quill is aligned correctly is crucial for smooth operation. Did you know that misalignment can lead to uneven cuts? Start by checking the bed level and using a dial indicator for accuracy. Adjust the quill with precision to reduce vibration. Always double-check your measurements after adjustments. This way, you can achieve the perfect finish in your projects. By keeping your lathe in top shape, you’ll enjoy woodworking more!Common Alignment Issues with Metal Lathes

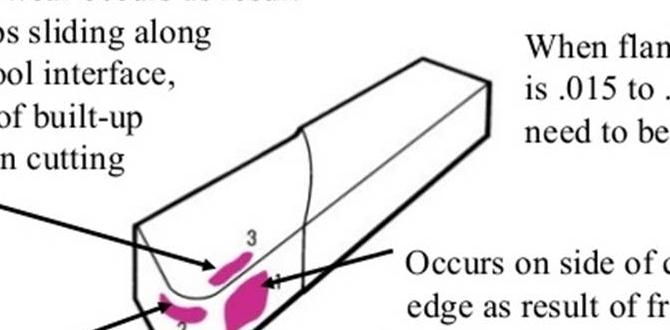

Description of typical problems causing misalignment.. Signs indicating misalignment in the lathe quill..Misalignment in metal lathes is common. It can happen for several reasons, and it may cause big problems. Common issues include:

- Worn bearings or supports

- Poor installation

- Temperature changes affecting material

- Damage or bending of the lathe frame

If your lathe quill is misaligned, you may notice uneven cuts or unusual vibrations. These signs show that something is wrong and needs fixing. Always check to ensure your lathe works well for the best results.

What are signs of misalignment in a lathe quill?

Signs of misalignment include uneven cuts, unusual noises, or vibrations during operation.

Tools Required for Lathe Alignment

List of essential tools for proper alignment.. Explanation of how to use each tool effectively..To align a lathe well, you need some simple tools. Here are the essentials:

- Dial Indicator: Use this tool to check if the spindle is straight. Place it on the tool rest and spin the lathe.

- Straight Edge: This helps you see if surfaces are flat. Lay it across the bed to spot any bumps or dips.

- Feeler Gauges: These small strips check gaps between parts. They help you know if the quill is tight against the chuck.

- Level: A simple bubble level ensures your lathe is balanced. Place it on the bed and adjust the lathe legs as needed.

Using these tools right can make your lathe work better. Proper lathe alignment helps you make smoother cuts and improves your overall project quality.

What tools do you need for lathe alignment?

You need a dial indicator, straight edge, feeler gauges, and a level for proper lathe alignment.

Step-by-Step Lathe Alignment Techniques

Detailed process for aligning the quill with illustrations.. Tips for checking and correcting alignment during the process..Aligning your lathe quill is a bit like herding cats. You want everything to line up perfectly, but sometimes, it just won’t cooperate! Start by using a dial indicator to check the quill’s position. Make adjustments if it’s off. If you’re lost, illustrations can guide your hands, but remember, practice makes perfect. Now, to check your work, use this handy table!

| Step | Action | Tip |

|---|---|---|

| 1 | Set up dial indicator | Keep it steady! |

| 2 | Measure quill alignment | Watch for wobbles! |

| 3 | Make necessary adjustments | A little twist goes a long way! |

By following these steps, you’ll have a quill that’s as straight as your grandmother’s old sewing needle! Happy aligning!

Maintaining Precision After Alignment

Best practices to maintain alignment over time.. Importance of regular inspections and adjustments..To keep your lathe working well, you must check and adjust it often. Regular inspections help catch small problems before they become big ones. Simple things can help maintain alignment over time. Here are some tips:

- Check the quill for any signs of wear.

- Use a dial indicator for precise measurements.

- Clean the machine regularly to avoid dust build-up.

- Lubricate moving parts to ensure smooth operation.

Staying on top of these tasks can save you from costly repairs and improve your work quality. Always remember, a little upkeep goes a long way!

Why is regular inspection important?

Regular inspection is key to keeping your machine precise and safe for use. It helps you find problems early, ensuring your work stays accurate.

Advanced Troubleshooting for Persistent Alignment Problems

Strategies for identifying and fixing difficult alignment issues.. Common mistakes to avoid during troubleshooting..Alignment problems can be as annoying as a cat in a bathtub! To solve these stubborn issues, start by checking the machine’s base for evenness. Next, inspect the tailstock and quill for any misalignment. A quick adjustment might save the day! Also, avoid skipping measurements; they can lead you down the wrong path. Keep an eye on common mistakes, like ignoring loose screws or wrong tool setups. Fix these, and you’ll be a lathe hero in no time!

| Common Mistakes | Fixes |

|---|---|

| Skipping measurements | Measure twice, cut once! |

| Ignoring loose screws | Tighten them up! |

| Wrong tool setups | Check your tool fit! |

Conclusion

In summary, aligning your metal lathe quill is essential for precise work. Remember to check the level and adjust accordingly. Using a dial indicator helps ensure accuracy. Practice these tips regularly for better results. We encourage you to explore more about lathe maintenance. The more you learn, the better your projects will turn out!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Alignment Tips For A Metal Lathe Quill:Sure! Here are some tips for keeping your metal lathe quill aligned. First, check the quill if it moves freely. You should adjust it if it feels tight. Next, use a dial indicator to see if it’s straight. Finally, make small changes and test it again. Always remember to turn off the lathe before making adjustments!

Sure! I’ll be happy to help you with that. Just let me know what question you want me to answer!

What Are The Common Signs That Indicate Misalignment In The Lathe Quill?If the lathe quill is misaligned, you might notice some common signs. First, the tool may make uneven cuts, leaving rough edges on your work. Second, you could see that the drill bit wobbles while spinning. Also, the quill might feel hard to move or sticky. Finally, listen for strange noises like grinding when you use the lathe.

How Can I Accurately Measure The Alignment Of The Lathe Quill With The Spindle?To measure the alignment of the lathe quill with the spindle, you can use a dial indicator. First, set the dial indicator on the spindle. Then, move the quill in and out, and watch the dial. If the numbers change a lot, it means they are not aligned. Adjust the quill until the measurements are steady.

What Tools Are Recommended For Adjusting The Lathe Quill To Ensure Proper Alignment?To adjust the lathe quill, you can use a few simple tools. A ruler helps you measure the distance. A level makes sure everything is straight. A wrench can help tighten or loosen any bolts. Make sure to check everything after you adjust!

How Often Should I Check And Adjust The Alignment Of The Quill On My Metal Lathe?You should check the alignment of the quill on your metal lathe often. It’s a good idea to do this after you change tools or make big adjustments. If you work on lots of different projects, check it at least once a week. This helps make sure your work stays accurate and clean. Taking care of your lathe means better results!

What Are The Best Practices For Maintaining The Alignment Of The Lathe Quill Over Time?To keep the lathe quill straight, check it often. You can use a ruler or a special tool to see if it is aligned. If it is off, adjust it carefully. Always clean the area around the quill to prevent dirt from causing problems. Lastly, make sure to store your lathe safely to protect it from bumps.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Alignment Tips For A Metal Lathe Quill:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some tips for keeping your metal lathe quill aligned. First, check the quill if it moves freely. You should adjust it if it feels tight. Next, use a dial indicator to see if it’s straight. Finally, make small changes and test it again. Always remember to turn off the lathe before making adjustments!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! I’ll be happy to help you with that. Just let me know what question you want me to answer!”}},{“@type”: “Question”,”name”: “What Are The Common Signs That Indicate Misalignment In The Lathe Quill?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the lathe quill is misaligned, you might notice some common signs. First, the tool may make uneven cuts, leaving rough edges on your work. Second, you could see that the drill bit wobbles while spinning. Also, the quill might feel hard to move or sticky. Finally, listen for strange noises like grinding when you use the lathe.”}},{“@type”: “Question”,”name”: “How Can I Accurately Measure The Alignment Of The Lathe Quill With The Spindle?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To measure the alignment of the lathe quill with the spindle, you can use a dial indicator. First, set the dial indicator on the spindle. Then, move the quill in and out, and watch the dial. If the numbers change a lot, it means they are not aligned. Adjust the quill until the measurements are steady.”}},{“@type”: “Question”,”name”: “What Tools Are Recommended For Adjusting The Lathe Quill To Ensure Proper Alignment?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the lathe quill, you can use a few simple tools. A ruler helps you measure the distance. A level makes sure everything is straight. A wrench can help tighten or loosen any bolts. Make sure to check everything after you adjust!”}},{“@type”: “Question”,”name”: “How Often Should I Check And Adjust The Alignment Of The Quill On My Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check the alignment of the quill on your metal lathe often. It’s a good idea to do this after you change tools or make big adjustments. If you work on lots of different projects, check it at least once a week. This helps make sure your work stays accurate and clean. Taking care of your lathe means better results!”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Maintaining The Alignment Of The Lathe Quill Over Time?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the lathe quill straight, check it often. You can use a ruler or a special tool to see if it is aligned. If it is off, adjust it carefully. Always clean the area around the quill to prevent dirt from causing problems. Lastly, make sure to store your lathe safely to protect it from bumps.”}}]}