Have you ever wondered how metal parts come together in machines? A lathe might be the answer. It’s a tool that shapes metal, wood, or plastic into useful items. But how does it work? This is where our lathe application guide comes in!

Imagine you’re working on a project. You want to create a lovely metal handle for a drawer. How do you make it just right? A metal lathe bench can help you achieve amazing results. With the right techniques, you can turn raw material into something beautiful.

Here’s a fun fact: the lathe is one of the oldest tools known to humankind! It has been used for thousands of years. Learning to use a lathe might feel like magic as you transform your ideas into real objects.

In this article, we’ll explore the basics and applications of metal lathes. Whether you’re a beginner or have some experience, there’s plenty to learn. Let’s dive in and discover how a metal lathe bench can become your new best friend in crafting!

Lathe Application Guide: Metal Lathe Bench Essentials

Lathe Application Guide: Metal Lathe Bench

Using a metal lathe bench can be fun and rewarding. It helps you create precise parts from metal blocks. This guide teaches you about different lathe operations, tools, and safety tips. Did you know that a lathe can turn a simple piece of metal into a beautiful sculpture? You’ll learn how to set up your lathe for various projects, whether for making toys or machine parts. Get ready to unleash your creativity and explore the world of metalworking!Understanding Metal Lathes

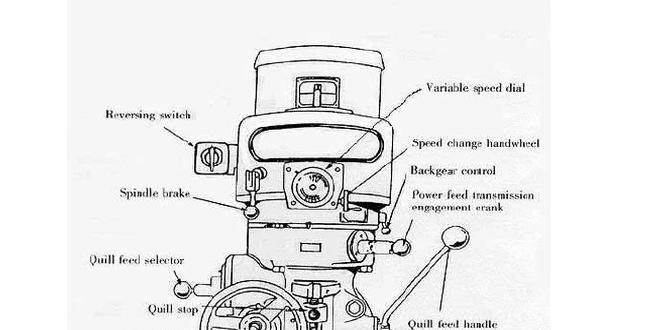

Definition and types of metal lathes. Key components and their functions.Metal lathes are machines that help shape metal into specific forms. Think of them as the sculptors in a metal shop. There are different types, like bench lathes for smaller projects and industrial lathes for big jobs. Key components include the headstock, tailstock, and bed. The headstock holds the motor, the tailstock supports the workpiece, and the bed keeps everything in line. It’s like a metal team where each part has a special job, and they all work together smoothly!

| Component | Function |

|---|---|

| Headstock | Holds the motor & controls speed |

| Tailstock | Supports the workpiece |

| Bed | Keeps all parts aligned |

In metal lathing, teamwork makes the dream work, ensuring that every cut is purposeful! Why did the metal lathe break up with the drill? It found a better fit! Now that’s a pun worth turning for!

Essential Features of a Metal Lathe Bench

Importance of stability and durability. Necessary accessories and tooling for optimal performance.Stability and durability are key for a metal lathe bench. A sturdy bench keeps the machine steady, reducing vibrations. This improves accuracy and safety. Strong materials like steel or hardwood work best. Accessories can enhance performance, including:

- Tool holders for organized storage

- V-blocks for holding workpieces securely

- Measuring tools to ensure precise cuts

- Chip trays to manage waste efficiently

With the right features, your lathe becomes a powerful tool for creativity and precision.

What is the importance of a stable lathe bench?

A stable lathe bench helps in making accurate cuts. It also keeps the machine safe during operation. A strong base means less chance of accidents.

Choosing the Right Metal Lathe for Your Needs

Factors to consider: size, power, and precision. Comparison between different models and brands.Choosing a metal lathe is exciting! Think about three main factors: size, power, and precision. These elements affect your work quality. A smaller lathe is good for small projects, while a larger one suits bigger tasks. Power shows how much work the lathe can handle. Precision is crucial for making detailed items. Compare brands and models carefully. Some options may be better for beginners, while others are made for experts.

What should I consider when buying a lathe?

The key points to check include:

- Size: Small or large?”

- Power: How strong is it?

- Precision: How accurate does it need to be?

Look closely at these aspects to find the best fit for your needs.

Setting Up Your Metal Lathe Bench

Stepbystep guide to assembling the lathe. Best practices for leveling and securing the bench.Assembling your metal lathe bench is easy! First, gather all parts and tools. Then, follow these steps:

- Read the instruction manual before starting.

- Connect the base to the legs securely.

- Attach the lathe to the bench using bolts.

- Check all pieces are tight and sturdy.

Next, leveling is important. A wobbly bench can cause problems. Use a bubble level to make sure it’s even. Adjust the legs if needed. Finally, secure the bench to the floor for safety.

How to level and secure your lathe bench?

Using a level is key. Adjust the feet until the bench is straight. This helps reduce vibrations.

Common Applications of Metal Lathes

Industrial applications in manufacturing. DIY projects and home workshops.Metal lathes are vital tools in many areas. In industry, they help create parts for machines and vehicles. Lathes make precision pieces that fit perfectly. This ensures high-quality products.

For DIY enthusiasts, metal lathes serve countless projects at home. You can craft everything from tools to decorative items. This adds fun and creativity to your workspace.

- Industrial Manufacturing: Used to produce engine parts and gears.

- DIY Projects: Perfect for creating custom tool handles or hardware.

- Home Workshops: Great for making furniture and artsy pieces.

What are some examples of projects you can do with a lathe?

You can make simple items like spindles or brackets. You can even craft unique gifts or hobby models. From small fixes to big projects, a lathe can help you create!

Maintenance and Troubleshooting Tips

Routine maintenance procedures for longevity. Common issues and how to resolve them.To keep your lathe working well, routine maintenance is key. Regular cleaning and lubrication can prevent problems down the line. Check belts for wear and tear. This can help your lathe last longer. If you notice strange noises or vibrations, tighten loose bolts and inspect parts. Here are some common issues and quick fixes:

- Check the power cord if the lathe won’t turn on.

- Replace dull tools for smooth cutting.

- Clean debris from the bed to avoid sticking.

With some care, your lathe will run smoothly for years. Remember, an ounce of prevention is worth a pound of cure!

What are some common problems with a lathe?

Common problems include the lathe not turning on, vibrations, and rough cuts. These issues can often be fixed with simple checks and adjustments.

Which maintenance tasks are most important?

- Regular cleaning of parts.

- Lubricating moving parts.

- Checking tool sharpness.

Conclusion

In summary, a lathe application guide for a metal lathe bench helps you understand how to use this tool effectively. You can make precise cuts and shapes in metal. Start with simple projects to build your skills. Remember, practice makes perfect! For deeper learning, check out online tutorials or ask an experienced friend for tips. Happy turning!FAQs

Sure! Here Are Five Related Questions About Metal Lathe Applications And Bench Setups:Sure! A metal lathe is a machine that helps you shape metal. You can use it to make parts for cars or tools. To set up your bench, make sure it’s sturdy and safe. Remember to keep your tools organized. Always wear safety gear when you work!

Sure! Please provide me the question you’d like me to answer.

What Are The Key Safety Practices To Follow While Operating A Metal Lathe On A Bench?When you use a metal lathe, always wear safety goggles to protect your eyes. Keep your hair tied back and wear tight clothes so nothing gets caught. Always keep your hands and tools away from moving parts. Make sure the area around the lathe is clean and free of clutter. Finally, follow all instructions and ask an adult for help if you’re unsure.

How Do You Properly Set Up A Metal Lathe On A Workbench For Optimal Performance?To set up a metal lathe on a workbench, first, find a flat and sturdy surface. Make sure the lathe is level by adjusting its feet. Next, secure it with bolts so it doesn’t move while we work. Keep enough space around it for safety and easy access to tools. Finally, check that all parts are clean and in good condition.

What Types Of Materials Are Best Suited For Machining On A Metal Lathe, And How Do They Affect Tool Selection?The best materials for a metal lathe are soft metals like aluminum and brass. These metals are easier to cut and shape. Harder metals, like steel and titanium, need stronger tools. When you choose a tool, think about the material you’re using. Softer materials can use sharp tools, while harder ones need tougher tools.

What Are The Common Maintenance Tasks Required To Keep A Bench-Mounted Metal Lathe In Good Working Condition?To keep your bench-mounted metal lathe in good shape, you should do a few simple things. First, clean it regularly by wiping off dirt and metal shavings. Next, make sure to oil the moving parts so they run smoothly. Check the belts for wear and replace them if they are damaged. Lastly, you should always keep the lathe in a dry place to prevent rust.

How Can You Troubleshoot Common Issues Encountered While Using A Metal Lathe, Such As Vibrations Or Inconsistency In Finished Parts?To fix vibrations on a metal lathe, you should check that all parts are tight. Make sure the lathe is on a steady surface and not wobbly. If your finished parts are not even, try adjusting the cutting tool. You can also check the speed—sometimes going slower helps. Lastly, always keep your lathe clean to avoid extra problems.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions About Metal Lathe Applications And Bench Setups:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A metal lathe is a machine that helps you shape metal. You can use it to make parts for cars or tools. To set up your bench, make sure it’s sturdy and safe. Remember to keep your tools organized. Always wear safety gear when you work!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide me the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Safety Practices To Follow While Operating A Metal Lathe On A Bench?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use a metal lathe, always wear safety goggles to protect your eyes. Keep your hair tied back and wear tight clothes so nothing gets caught. Always keep your hands and tools away from moving parts. Make sure the area around the lathe is clean and free of clutter. Finally, follow all instructions and ask an adult for help if you’re unsure.”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up A Metal Lathe On A Workbench For Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe on a workbench, first, find a flat and sturdy surface. Make sure the lathe is level by adjusting its feet. Next, secure it with bolts so it doesn’t move while we work. Keep enough space around it for safety and easy access to tools. Finally, check that all parts are clean and in good condition.”}},{“@type”: “Question”,”name”: “What Types Of Materials Are Best Suited For Machining On A Metal Lathe, And How Do They Affect Tool Selection?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The best materials for a metal lathe are soft metals like aluminum and brass. These metals are easier to cut and shape. Harder metals, like steel and titanium, need stronger tools. When you choose a tool, think about the material you’re using. Softer materials can use sharp tools, while harder ones need tougher tools.”}},{“@type”: “Question”,”name”: “What Are The Common Maintenance Tasks Required To Keep A Bench-Mounted Metal Lathe In Good Working Condition?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your bench-mounted metal lathe in good shape, you should do a few simple things. First, clean it regularly by wiping off dirt and metal shavings. Next, make sure to oil the moving parts so they run smoothly. Check the belts for wear and replace them if they are damaged. Lastly, you should always keep the lathe in a dry place to prevent rust.”}},{“@type”: “Question”,”name”: “How Can You Troubleshoot Common Issues Encountered While Using A Metal Lathe, Such As Vibrations Or Inconsistency In Finished Parts?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix vibrations on a metal lathe, you should check that all parts are tight. Make sure the lathe is on a steady surface and not wobbly. If your finished parts are not even, try adjusting the cutting tool. You can also check the speed—sometimes going slower helps. Lastly, always keep your lathe clean to avoid extra problems.”}}]}