Have you ever wondered how metal parts are made? A lathe is an amazing machine that shapes metal into useful items. Understanding lathe applications can help anyone, from beginners to experts.

This article will be your guide to using a metal lathe. We’ll explore how to design with CAD software, which stands for Computer-Aided Design. CAD helps you create designs that come to life on the lathe.

Did you know that lathes have been around for thousands of years? They started as simple tools but now are vital in modern factories. With the right techniques and tools, you can create precise and beautiful pieces easily.

Whether you’re making parts for a robot or crafting a unique gift, this guide will help you. Get ready to dive into the fascinating world of metal lathe applications and CAD design!

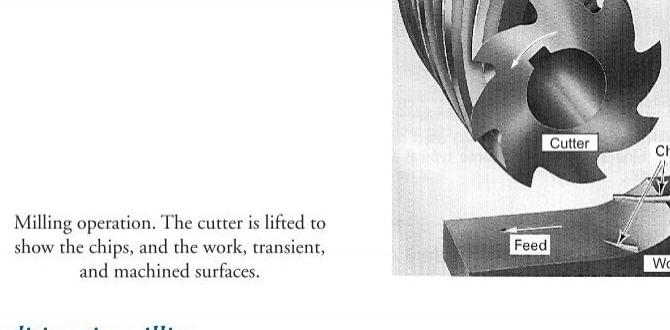

Lathe Application Guide: Metal Lathe Cad Design Insights Introduction A Metal Lathe Is A Versatile Machine Tool That Has Been A Cornerstone In Manufacturing And Engineering For Centuries. Understanding Lathe Applications, Particularly In The Context Of Cad (Computer-Aided Design), Can Significantly Enhance The Efficiency And Precision Of Metalworking Tasks. In This Article, We Will Delve Into The Various Applications Of Metal Lathes, Supported By Cad Design Principles To Guide Users In Optimizing Their Projects. What Is A Lathe? A Lathe Is A Machine That Rotates A Workpiece Against A Cutting Tool To Remove Material And Shape It Into Desired Forms. Metal Lathes, Specifically, Are Used For Machining Metal Materials Into Precise Dimensions And Finishes, Making Them Integral For Many Industries, Including Automotive, Aerospace, And Manufacturing. Applications Of Metal Lathes Metal Lathes Serve A Multitude Of Applications, Including: 1. **Turning**: This Is The Primary Function Of A Lathe, Where Material Is Removed From A Rotating Workpiece To Achieve Cylindrical Shapes. 2. **Facing**: In This Process, The Tool Moves Across The End Of The Workpiece To Create A Flat Surface. 3. **Drilling**: Metal Lathes Can Also Be Used To Drill Holes In The Workpiece At Precise Locations. 4. **Boring**: This Enlarges Existing Holes To Increase Their Diameter And Achieve A Smoother Finish. 5. **Thread Cutting**: Essential For Creating Screw Threads, Metal Lathes Can Produce Various Thread Profiles With High Accuracy. Integrating Cad Design With Metal Lathe Work Using Cad In Conjunction With Metal Lathe Operations Streamlines The Design And Manufacturing Process. Here’S How: – **Precision Design**: Cad Software Allows For Precise Modeling Of Components Before They Are Machined. This Ensures The Final Product Meets Exact Specifications. – **Easy Modifications**: Unlike Traditional Hand-Drawn Designs, Cad Models Can Be Easily Altered. This Flexibility Helps In Adapting Designs Without Starting From Scratch. – **Simulation**: Cad Programs Often Include Simulation Features To Anticipate Challenges Before Physical Machining Begins, Reducing Material Waste And Costs. – **Documentation**: Cad Designs Provide Clear Documentation Of Dimensions, Tolerances, And Machining Processes, Ensuring All Team Members Are On The Same Page. Steps To Create A Cad Design For Lathe Applications 1. **Define The Objective**: Understand The Specifications And Requirements Of The Part To Be Created. 2. **Select The Right Software**: Popular Cad Tools For Lathe Applications Include Autocad, Solidworks, And Fusion 360. 3. **Create The 3D Model**: Begin By Modeling The Component, Paying Special Attention To Dimensions And Tolerances. 4. **Generate Toolpaths**: Most Cad/Cam (Computer-Aided Manufacturing) Software Can Generate The Necessary Toolpaths For Machining. 5. **Review And Simulate**: Run A Simulation To Validate The Machining Process And Identify Potential Issues. 6. **Export And Machine**: Once Satisfied With The Design, Export The Files For Machining On A Metal Lathe. Conclusion A Thorough Understanding Of The Lathe Application Guide For Metal Lathe Cad Design Can Enhance The Quality And Efficiency Of Machining Operations. By Integrating Advanced Cad Methodologies, Metalworking Can Achieve New Heights Of Accuracy And Innovation. Incorporating These Insights Into Your Metal Lathe Projects Will Not Only Streamline The Process But Also Empower You To Create Intricate Designs That Meet The Highest Standards In The Industry.

Lathe Application Guide: Metal Lathe CAD Design

Metal lathes play a crucial role in shaping and crafting parts. This guide helps you understand how to use CAD design effectively with lathes. You’ll discover essential tips for selecting materials and creating precise models. Do you know that proper design can save time and reduce waste? Learning how to integrate CAD with lathes can make your projects more efficient and fun! With the right tools and knowledge, anyone can create amazing metalwork.Understanding Metal Lathes

Definition and purpose of metal lathes. Types of metal lathes and their unique features.A metal lathe is a tool that helps shape metal into different forms. Think of it like a giant pencil sharpener for metal! You put a metal rod in, and it spins around while a cutting tool removes material. There are different types of metal lathes. Some are tiny and portable, while others are huge and can take on big projects. Each type has its special features, making it easier for workers to create everything from small screws to large engine parts.

| Type of Metal Lathe | Unique Features |

|---|---|

| Benchtop Lathe | Small, portable, great for hobbies! |

| CNC Lathe | Computer-controlled, super precise! |

| Toolroom Lathe | Used for making tools and parts with high accuracy. |

So, if you ever want to make something cool out of metal, a metal lathe is your best friend! Just keep your fingers away from the spinning part, or you might end up with a funny story—but not a good one!

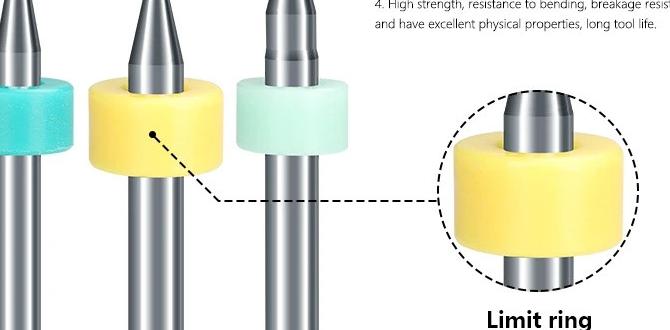

Essential Components of Metal Lathes

Detailed breakdown of key components (spindle, bed, tailstock, etc.). Importance of each component in CAD design.Metal lathes have several essential parts that work together to shape metal. Here’s a closer look at the key components:

- Spindle: This is where the workpiece spins. It helps create precise shapes.

- Bed: The bed holds everything in place. A sturdy bed ensures accuracy during cutting.

- Tailstock: It supports long pieces and helps with drilling. This part is especially useful for creating holes.

- Carriage: It moves tools across the metal. A smooth carriage leads to better designs.

Each component is important in CAD design. They help create detailed drawings and models. Understanding these parts leads to better planning and results.

What are the main functions of a metal lathe?

The main functions of a metal lathe include shaping, cutting, and finishing metal parts. These tasks are vital for creating tools and machinery.

Step-by-Step Guide to Designing a Metal Lathe in CAD

Initial planning and design considerations. Detailed walkthrough of the CAD modeling process.Starting your metal lathe design in CAD is like planning a fun road trip. First, you need to map out where you’re going! Think about the lathe’s size, style, and materials. Next, move on to the fun part: modeling. Open your CAD software and let the adventure begin! Start with simple shapes and gradually add details like the motor and tool holders. Remember, even the best designs start with a few funny doodles, so don’t hesitate to sketch your crazy ideas first!

| Design Consideration | Description |

|---|---|

| Size | Decide how big the lathe will be. It should fit in your workspace! |

| Materials | Pick materials that are strong and fit your design. |

| Parts | Include all important parts like motors and tool holders. |

Common Applications of Metal Lathes

Industrial uses (automotive, aerospace, etc.). Custom projects and hobbyist applications.Metal lathes are like magic wands in factories! They shape and cut metal into cool parts for industries like automotive and aerospace. Imagine cars zooming by with precisely made engine parts and airplanes soaring thanks to expertly crafted components. Hobbyists, too, love these machines! They use them for fun projects, making everything from toy parts to unique gifts. Metal lathes help dreams turn into metal reality!

| Application Type | Example |

|---|---|

| Industrial | Engine parts for cars |

| Aerospace | Custom fittings for aircraft |

| Hobbyist | Unique gifts and toys |

Best Practices for Safety and Maintenance When Using Metal Lathes

Safety precautions during operation. Routine maintenance tips to ensure longevity.Using metal lathes can be safe and fun if you follow some simple rules. First, always wear safety gear like goggles and gloves. Keep your workspace clean and organized. Don’t wear loose clothing or jewelry. Always check the machine before use. Regular maintenance helps your lathe last longer. Lubricate moving parts weekly. Keep the machine clean by removing metal shavings. Inspect belts and gears for wear. Following these practices will help you work safely.

What are the safety precautions for using a metal lathe?

Safety gear like goggles and gloves is essential. Always keep your workspace clean to avoid accidents. Regularly check the machine before use to ensure it’s in good shape.

Routine Maintenance Tips

- Lubricate moving parts weekly.

- Remove metal shavings after each use.

- Inspect belts and gears for wear regularly.

Comparing Different Metal Lathes for CAD Projects

Factors to consider when selecting a metal lathe. Pros and cons of various models available on the market.Choosing a metal lathe for your CAD projects can be difficult. Consider several key factors. Look for size, power, and ease of use. Each lathe has its strengths and weaknesses. Below are the pros and cons of popular models:

- Mini Lathe: Good for small projects, but limited in size.

- Bench Lathe: Versatile and powerful, yet heavier and less portable.

- Engine Lathe: Great for heavy-duty tasks, but can be more costly.

Evaluate what you need most. This will help you find the right lathe.

What should I consider when selecting a metal lathe?

Think about size, power, and the type of projects. Look at reviews to find the model that fits your needs best.

Future Trends in CAD Design for Metal Lathes

Emergence of new technologies in metal lathe design. Predictions for the evolution of CAD tools and applications in this space.New technologies are shaking things up in metal lathe design. Soon, we might see robots getting in on the action—talk about a crazy workplace! CAD tools are also evolving. They’re becoming smarter and easier to use. Designers will have more features to play with, making their work faster and more fun. Imagine a future where CAD does your math while you sip your coffee!

| Future Trends | Predictions |

|---|---|

| Advanced Automation | More robots joining the metal lathe party! |

| Smart CAD Tools | Cymurgy features for easier design! |

Conclusion

In conclusion, a lathe application guide helps you understand how to use metal lathes effectively. With CAD design, you can visualize your projects better. We encourage you to try designing simple parts or read more about metalworking. Exploring these topics will make you skilled and confident in your crafting journey. Start today and see what you can create!FAQs

What Are The Key Features And Specifications To Consider When Selecting A Metal Lathe For Cad Design Applications?When you choose a metal lathe for CAD design, think about size first. You want one that fits your workspace. Check the speed settings; more options let you work better. Look for a strong motor to handle tough materials. Lastly, make sure it’s easy to use, so you can enjoy your projects!

How Can Cad Software Be Integrated With Metal Lathe Operations To Improve Production Efficiency And Accuracy?We can use CAD software, which stands for Computer-Aided Design, to help with metal lathes. First, we create a design on the computer. This design tells the lathe exactly what to do. It makes cutting parts easier and more accurate. Because of this, we save time and make fewer mistakes while producing items.

What Are The Most Common Types Of Metal Lathe Projects That Can Be Designed Using Cad Tools?You can design many cool projects using a metal lathe and CAD tools. Common projects include custom parts, handles, and tools. You might also create gears, spacers, or decorative items. These projects help you learn how to shape metal better. It’s fun to see your ideas come to life!

What Best Practices Should Be Followed When Creating Cad Designs Specifically For Metal Lathe Machining?When you create CAD designs for metal lathe machines, make sure your parts have clear shapes. You should avoid sharp corners because they can be hard to cut. Keep the sizes simple, and follow standard measurements. Always check your design for mistakes before starting. Lastly, make sure to use the right materials for your project.

How Do Tooling And Fixture Design In Cad Impact The Performance And Outcomes Of Metal Lathe Operations?Tooling and fixture design in CAD, which stands for Computer-Aided Design, helps us create better shapes and parts for our projects. Good designs make sure that everything fits together well when using a metal lathe, which is a machine that cuts metal. When we have the right tools and fixtures, we can work faster and make fewer mistakes. This means our final products are better and we save time. In short, smart designs in CAD lead to great results when we use a metal lathe.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Features And Specifications To Consider When Selecting A Metal Lathe For Cad Design Applications? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you choose a metal lathe for CAD design, think about size first. You want one that fits your workspace. Check the speed settings; more options let you work better. Look for a strong motor to handle tough materials. Lastly, make sure it’s easy to use, so you can enjoy your projects!”}},{“@type”: “Question”,”name”: “How Can Cad Software Be Integrated With Metal Lathe Operations To Improve Production Efficiency And Accuracy? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use CAD software, which stands for Computer-Aided Design, to help with metal lathes. First, we create a design on the computer. This design tells the lathe exactly what to do. It makes cutting parts easier and more accurate. Because of this, we save time and make fewer mistakes while producing items.”}},{“@type”: “Question”,”name”: “What Are The Most Common Types Of Metal Lathe Projects That Can Be Designed Using Cad Tools? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can design many cool projects using a metal lathe and CAD tools. Common projects include custom parts, handles, and tools. You might also create gears, spacers, or decorative items. These projects help you learn how to shape metal better. It’s fun to see your ideas come to life!”}},{“@type”: “Question”,”name”: “What Best Practices Should Be Followed When Creating Cad Designs Specifically For Metal Lathe Machining? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you create CAD designs for metal lathe machines, make sure your parts have clear shapes. You should avoid sharp corners because they can be hard to cut. Keep the sizes simple, and follow standard measurements. Always check your design for mistakes before starting. Lastly, make sure to use the right materials for your project.”}},{“@type”: “Question”,”name”: “How Do Tooling And Fixture Design In Cad Impact The Performance And Outcomes Of Metal Lathe Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Tooling and fixture design in CAD, which stands for Computer-Aided Design, helps us create better shapes and parts for our projects. Good designs make sure that everything fits together well when using a metal lathe, which is a machine that cuts metal. When we have the right tools and fixtures, we can work faster and make fewer mistakes. This means our final products are better and we save time. In short, smart designs in CAD lead to great results when we use a metal lathe.”}}]}