Have you ever wondered how metal parts are created? It’s all about tools and machines. One of the most important tools is the lathe. But what makes a lathe truly effective? It’s the chuck! This handy device holds the metal firmly so you can shape it just right.

Imagine you want to build a small model of a car. You need precise parts that fit together perfectly. A metal lathe chuck plays a key role in making those parts. It grips the metal securely while the lathe spins it, allowing for accurate cuts. But there is so much more to learn about its functions and types.

Did you know the lathe can produce items ranging from simple screws to complex gears? With the right chuck, the possibilities are endless! This article will guide you through the different lathe applications and help you choose the best metal lathe chuck for your projects. Get ready to dive into the amazing world of lathes!

Lathe Application Guide: Understanding Metal Lathe Chuck Usage

Lathe Application Guide: Metal Lathe Chuck

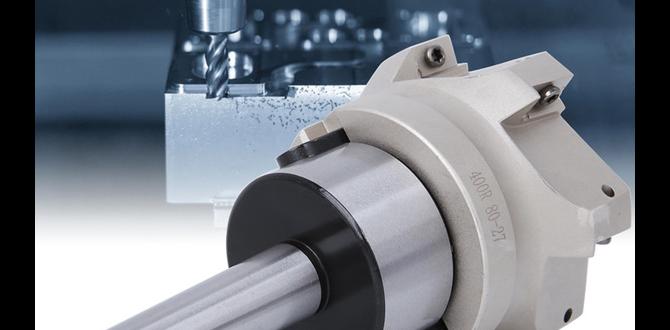

Metal lathe chucks are essential tools in machining. They securely hold various workpieces for precise cutting and shaping. A good chuck ensures accuracy and consistency, which is vital for quality workmanship. Have you ever wondered how a small piece of metal can turn into a beautiful shape? Understanding different chuck types, such as three-jaw and four-jaw, helps in selecting the right fit for your projects. Get ready to enhance your skills and bring your creative ideas to life!Understanding Metal Lathe Chucks

Definition and function of a metal lathe chuck. Different types of chucks and their specific uses.A metal lathe chuck is a handy tool that holds workpieces while they spin. Think of it as a friendly hug for metal! There are several types of chucks, each designed for different jobs. Some can hold square parts, while others grip round ones like a pro. Here’s a quick look at some common types:

| Type | Use |

|---|---|

| 3-Jaw Chuck | Best for round objects. |

| 4-Jaw Chuck | Perfect for uneven shapes. |

| Collet Chuck | Great for precision work. |

Choosing the right chuck can make all the difference, like picking the right shoes for a dance party!

Choosing the Right Chuck for Your Project

Factors to consider when selecting a chuck. Matching chuck type to material and project requirements.Selecting a chuck for your project is like choosing the right tool for a superhero! First, think about the material you’ll be working with. Soft metals need a different chuck than hard ones. Next, consider the project requirements. Are you making precision parts or something chunky? Lastly, don’t forget to match the chuck type to your lathe. A poor match can lead to mishaps. Here’s a handy table to remember the key factors:

| Factor | Considerations |

|---|---|

| Material Type | Soft metal, hard metal, or plastic |

| Project Type | Precision work or thick pieces |

| Chuck Type | 3-jaw, 4-jaw, or collet |

Picking the right chuck means less headache later, so choose wisely, and may the chuck be forever in your favor!

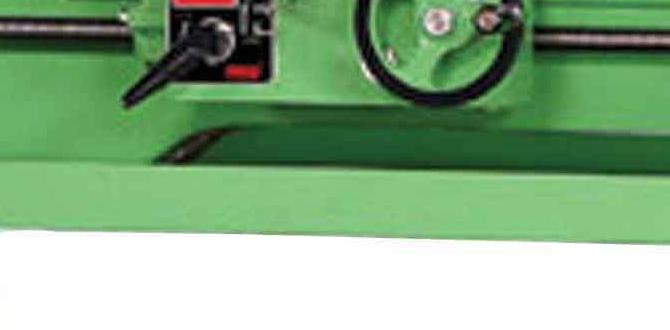

Setup and Installation of Metal Lathe Chucks

Stepbystep installation process. Common mistakes to avoid during setup.Setting up a metal lathe chuck can feel like putting together a puzzle with your eyes closed. But don’t worry! Follow these easy steps:

| Step | Description |

|---|---|

| 1 | Clean the lathe and chuck to remove any dust. |

| 2 | Align the chuck with the spindle. Spin it to check. |

| 3 | Tighten the bolts, but not too tight—like a hug, not a bear hug! |

| 4 | Test the chuck by rotating it. Listen for any funny noises. |

Now, let’s dodge some common mistakes. One big one is not securing the chuck well. It’s like trying to ride a bike with flat tires—no fun at all! Also, don’t forget to check the alignment. A crooked chuck sends your work on a wild ride. Following these tips ensures a smoother setup, so you can spend more time creating and less time fixing. Happy lathing!

Maintenance and Care for Longevity

Recommended cleaning and lubrication practices. Signs of wear and when to replace your chuck.Keeping your lathe chuck clean is like brushing your teeth—it helps prevent bigger problems later! Use a soft cloth and mild cleaner to wipe off grime. For lubrication, a few drops of oil can work wonders. Check for signs of wear, like rust or cracks. If your chuck looks like it’s had a rough day, it might be time to replace it. Remember, a well-cared chuck is a happy chuck! Just don’t forget, chucks don’t like water—so keep them dry!

| Maintenance Tip | Action |

|---|---|

| Cleaning | Wipe with soft cloth and mild cleaner |

| Lubrication | Apply a few drops of oil regularly |

| Signs of Wear | Look for rust or cracks |

| Replacement | Swap it out if it looks damaged |

Advanced Techniques Using Metal Lathe Chucks

Specialized techniques for enhanced precision. Tips for using a chuck effectively in complex projects.Using a metal lathe chuck can improve your work in many ways. One advanced technique is to ensure the chuck is properly tightened. This helps keep your material stable during cutting. Precision is key in complex projects. Always check your alignment before starting. Here are some helpful tips:

- Use a dial indicator for accuracy.

- Adjust your speeds based on materials.

- Keep your tools clean and sharp.

These methods can lead to better outcomes and smoother operations.

What are the best tips for using a metal lathe chuck?

Ensure tightness, check alignment, and use the right speed for materials. These tips lead to precision and better project results!

Common Problems and Troubleshooting

Identifying issues with chuck performance. Solutions for common problems encountered.Sometimes, your lathe chuck may act like it’s in a bad mood. Maybe the workpiece is slipping or making weird noises. Don’t sweat it; problems can happen to the best of us! First, check for jaw alignment. Misalignment can block your work, and it’s like a stubborn door refusing to open. If things are still off, pay attention to wear and tear on the chuck. A worn chuck might need a little TLC, or maybe a trip to the chuck spa! Below is a quick table to solve some common chuck issues:

| Problem | Solution |

|---|---|

| Workpiece slipping | Check jaw alignment and tighten screws. |

| Chuck making noise | Inspect for wear and lubricate if needed. |

| Uneven cuts | Ensure the workpiece is secure and properly centered. |

With these steps, your chuck will be ready to work happily again. Just think of it as a cranky friend in need of a snack and a nap!

Safety Considerations When Using Metal Lathe Chucks

Safety gear and precautions to take. Best practices for ensuring safe operation.Using metal lathe chucks safely is super important. Always wear protective gear, like goggles and gloves. You don’t want your fingers to meet Mr. Lathe, do you? Keeping the area clean helps too—no one likes tripping over sawdust! Also, make sure to double-check your setups before starting the machine. A little twist here or there can save you from surprises. Following these simple rules can turn your lathe experiences from scary to *very cool*!

| Safety Gear | Best Practices |

|---|---|

| Goggles | Check settings twice before operating |

| Gloves | Keep work area clean |

| Ear Protection | Stay focused on the task |

Conclusion

In conclusion, a lathe application guide for metal lathe chucks helps you choose and use the right tools. You learned about different chuck types and their specific uses. Understanding these basics makes your projects easier and more successful. Now, take the next step by trying out a chuck yourself or reading more about advanced techniques. Happy crafting!FAQs

What Are The Different Types Of Chucks Used In Metal Lathes, And How Do They Differ In Functionality And Application?There are a few types of chucks used in metal lathes. The most common ones are the three-jaw chuck and the four-jaw chuck. A three-jaw chuck holds things tightly and quickly because all the jaws move at once. A four-jaw chuck can hold odd shapes and lets you adjust each jaw separately. This means you can use them for different projects depending on what you need to do.

How Do You Properly Mount And Align A Workpiece In A Metal Lathe Chuck To Ensure Precision Machining?To mount a workpiece in a metal lathe chuck, first, clean both the chuck and the workpiece. Then, place the workpiece in the middle of the chuck. Close the chuck’s jaws gently around it. Use a tool to check if the workpiece is straight. If it wobbles, adjust it until it spins evenly. This helps us make precise cuts.

What Maintenance Practices Should Be Followed To Keep A Metal Lathe Chuck In Optimal Working Condition?To keep a metal lathe chuck working well, we should clean it regularly. Use a brush and some oil to get rid of dirt and rust. Check the chuck for any loose parts and tighten them if needed. Always store the chuck in a dry place to prevent rust. Finally, make sure to use it carefully to avoid damage.

What Safety Precautions Must Be Taken When Operating A Metal Lathe With A Chuck?When using a metal lathe with a chuck, first wear safety glasses. This protects your eyes from metal chips. Always tie back long hair and avoid loose clothing. Keep your fingers away from moving parts. Lastly, check that all tools are in good condition before you start.

How Can You Choose The Right Size And Type Of Chuck Based On The Specific Projects You Are Working On With A Metal Lathe?To choose the right size and type of chuck for a metal lathe, first think about the project you want to do. If you’re working with small pieces, pick a smaller chuck. For bigger pieces, use a larger chuck. Different projects may need a different type, like a three-jaw or four-jaw chuck, so check what suits your needs best. Always make sure the chuck fits your lathe properly.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Different Types Of Chucks Used In Metal Lathes, And How Do They Differ In Functionality And Application? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “There are a few types of chucks used in metal lathes. The most common ones are the three-jaw chuck and the four-jaw chuck. A three-jaw chuck holds things tightly and quickly because all the jaws move at once. A four-jaw chuck can hold odd shapes and lets you adjust each jaw separately. This means you can use them for different projects depending on what you need to do.”}},{“@type”: “Question”,”name”: “How Do You Properly Mount And Align A Workpiece In A Metal Lathe Chuck To Ensure Precision Machining? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To mount a workpiece in a metal lathe chuck, first, clean both the chuck and the workpiece. Then, place the workpiece in the middle of the chuck. Close the chuck’s jaws gently around it. Use a tool to check if the workpiece is straight. If it wobbles, adjust it until it spins evenly. This helps us make precise cuts.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Followed To Keep A Metal Lathe Chuck In Optimal Working Condition? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a metal lathe chuck working well, we should clean it regularly. Use a brush and some oil to get rid of dirt and rust. Check the chuck for any loose parts and tighten them if needed. Always store the chuck in a dry place to prevent rust. Finally, make sure to use it carefully to avoid damage.”}},{“@type”: “Question”,”name”: “What Safety Precautions Must Be Taken When Operating A Metal Lathe With A Chuck? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe with a chuck, first wear safety glasses. This protects your eyes from metal chips. Always tie back long hair and avoid loose clothing. Keep your fingers away from moving parts. Lastly, check that all tools are in good condition before you start.”}},{“@type”: “Question”,”name”: “How Can You Choose The Right Size And Type Of Chuck Based On The Specific Projects You Are Working On With A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To choose the right size and type of chuck for a metal lathe, first think about the project you want to do. If you’re working with small pieces, pick a smaller chuck. For bigger pieces, use a larger chuck. Different projects may need a different type, like a three-jaw or four-jaw chuck, so check what suits your needs best. Always make sure the chuck fits your lathe properly.”}}]}