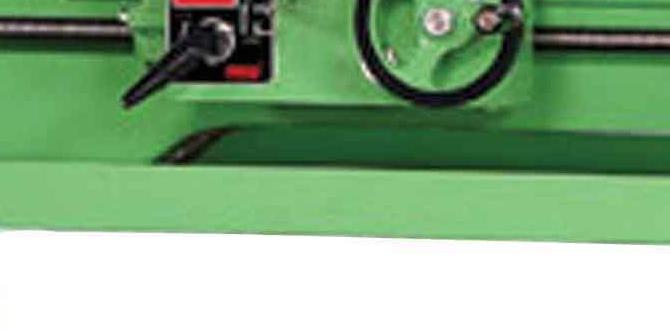

Have you ever wondered how metal objects like car parts or tools are made? It’s all thanks to machines like the lathe. This powerful tool spins metal and shapes it into different forms. But what makes it easier to use? Enter the metal lathe controller board!

This small but mighty device controls the lathe with precision. It helps users cut, shape, and design metal pieces quickly. Whether you are a beginner or a pro, understanding lathe applications can help you create amazing projects.

Did you know that lathes have been around for thousands of years? They were used by ancient people to craft items from wood and metal. Today, we have advanced technology that makes working with lathes much simpler.

In this article, we will explore the lathe application guide. You will learn how to choose the right metal lathe controller board for your needs. By the end, you’ll feel confident to tackle your next metalworking project!

Lathe Application Guide: Metal Lathe Controller Board Explained

Lathe Application Guide: Metal Lathe Controller Board

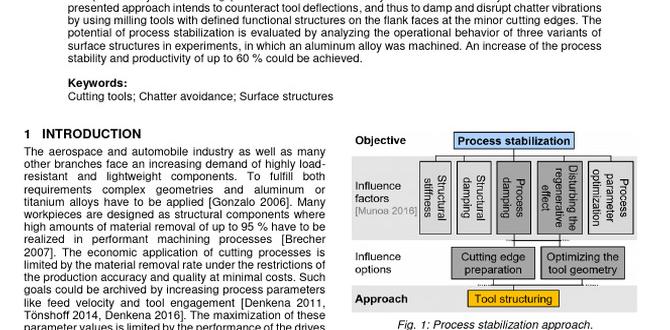

Discover how a metal lathe controller board can transform your crafting experience! These boards are essential for precise control and automation. Do you want smoother cuts and better designs? A good controller board helps you achieve that with ease. Learn about the different features that make these boards stand out. With the right knowledge, you can enhance your metalworking skills and create amazing projects. Imagine crafting with accuracy like never before!Understanding Metal Lathes

Definition and purpose of metal lathes. Importance of controller boards in lathe operations.Metal lathes are machines that shape metal into different forms, like magic wands but for metal. They spin the material while cutting tools carve it into desired shapes. They play a key role in manufacturing. The controller board acts like a brain, guiding the lathe’s movements. It helps you cut with precision, making sure everything is perfect. Without it, things could get messy—like trying to bake a cake without a recipe! That’s why having a good controller board is super important.

| Function | Importance |

|---|---|

| Shape Metal | Creates various forms for projects |

| Controller Board | Ensures precise operations |

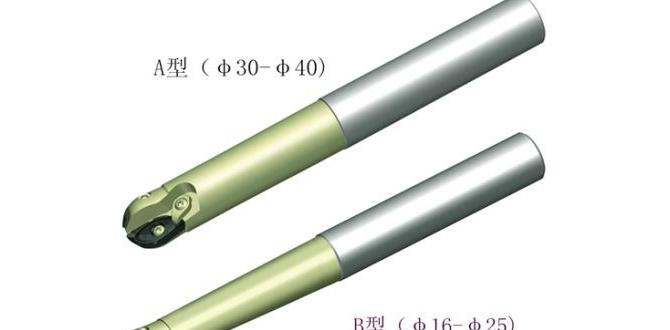

Types of Metal Lathes

Conventional vs. CNC lathes. Advantages and disadvantages of each type.There are two main types of metal lathes: conventional and CNC. Conventional lathes are like the grandpas of the workshop. They require hands-on operation, which is good for learning basics. They are less expensive but can be slower. On the flip side, CNC lathes are the tech wizards. They run on computers, making them fast and precise. However, they can be pricey and need programming skills. Here’s a quick look at the pros and cons:

| Type | Advantages | Disadvantages |

|---|---|---|

| Conventional Lathes | Cost-effective, hands-on learning | Slower speed, more physical labor |

| CNC Lathes | High precision, fast production | Higher cost, requires programming |

No matter the choice, make sure to tighten all those bolts—nobody likes a loose screw while working!

Choosing the Right Controller Board

Factors to consider (compatibility, features, price). Comparison of popular controller boards in the market.Picking the right controller board can feel like a treasure hunt. First, check for compatibility with your lathe model. Some boards are like puzzle pieces; they only fit one way! Next, think about the features you need. Do you want fancy programs or just basic controls? Lastly, compare prices. It’s best to find a board that doesn’t break the bank but still does the job.

| Controller Board | Compatibility | Features | Price |

|---|---|---|---|

| Board A | Model X | Basic Control | $100 |

| Board B | Model Y | Advanced Features | $150 |

| Board C | Model Z | Customizable | $200 |

Check user reviews, too! Someone might say, “This board changed my life!” or “It’s like trying to teach a cat to fetch!” Choose wisely. The perfect board awaits!

Installation Process for Controller Boards

Stepbystep installation guide. Common challenges and troubleshooting tips.Installing a controller board can be exciting! Follow these steps for a smooth setup:

- First, ensure you have all parts ready.

- Next, carefully read the instructions.

- Connect the wires based on the guide.

- Secure the board in place.

- Finally, power it on and test if it works.

Sometimes, issues can arise. If the board doesn’t turn on, check if the wires are tight. If it runs slowly, try rebooting the system. Remember, patience is key!

What are common issues when installing a controller board?

Some common problems include: loose connections, incorrect wiring, or power issues. Check these to solve your problems quickly.

Programming and Using the Controller Board

Basics of programming for lathe operations. Practical applications and examples.Programming a lathe controller board can seem tricky, but it’s fun! Start with the basic commands. You can control speed, direction, and length of cuts. Using simple programs, you can make shapes like cylinders or cones. Here are some common tasks:

- Setting the speed.

- Choosing the right tool.

- Making precise cuts.

For example, you can program a lathe to create a toy car’s wheels. It’s all about practice and understanding the controls!

What is the easiest way to learn lathe programming?

The easiest way is by starting with simple projects and following tutorials. Hands-on practice helps you learn faster.

Safety Measures While Operating Metal Lathes

Essential safety equipment and practices. Importance of adhering to safety standards.Working with metal lathes can be exciting, but safety always comes first! Always wear protective gear like goggles and gloves. They are your best friends when flying metal shavings try to take out your eye or scratch your hand. Following safety standards keeps you safe and sound. If you don’t protect yourself, it’s like inviting trouble to a party! Remember, machines are great, but safety is the real superstar.

| Essential Safety Equipment | Practices to Follow |

|---|---|

| Safety goggles | Always check your machine before use |

| Gloves | Keep your workspace neat and tidy |

| Ear protection | Never wear loose clothing |

Maintenance and Troubleshooting of Metal Lathes

Regular maintenance routines for optimal performance. Common issues and their solutions involving controller boards.Taking care of your metal lathe is important for it to work well. Regular maintenance helps prevent problems and keeps everything running smoothly. Here are some easy steps to follow:

- Check oil levels often.

- Clean the lathe after each use.

- Inspect belts and wires for damage.

- Keep the controller board dust-free.

Sometimes lathes can have issues. Common problems often relate to the controller board. Here are a few examples:

- If the machine won’t start, check the power supply.

- If it stops mid-use, there may be a faulty connection.

- If it runs slowly, check for dust on the board.

Fixing these problems quickly helps your lathe last longer. Remember, a little care can go a long way!

What are common issues with metal lathe controller boards?

Controller boards may face issues like power failures and connectivity problems. Keeping the board clean and checking for loose wires can help fix these problems.How often should I maintain my metal lathe?

You should maintain your metal lathe after every use and perform a full inspection monthly.Conclusion

In summary, a lathe application guide helps you understand metal lathe controller boards better. These boards control the lathe’s movements for precise work. We learned about their features and uses. Now, you can explore different boards and choose the best one for your projects. Keep practicing, and don’t hesitate to read more to enhance your skills!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Application Guides And Metal Lathe Controller Boards:Sure! A lathe is a tool that helps shape metal into different forms. You can use it to make things like toys or parts for machines. A controller board is like the brain of the lathe; it tells the machine what to do. If you want to learn how to use a lathe, guides can help you understand the steps. Using these tools safely is very important, so always ask for help if you need it!

Sure! Please provide the question you would like me to answer, and I’ll be happy to help!

What Are The Key Features To Consider When Selecting A Controller Board For A Metal Lathe?When choosing a controller board for a metal lathe, think about a few important things. First, make sure it has enough power to run your lathe. Second, check if it can connect with your computer easily. You also want a board that has good safety features. Lastly, see if it has options for upgrading in the future.

How Do Various Controller Board Types (Such As Cnc Vs. Manual) Affect The Operation Of A Metal Lathe?Different controller boards change how a metal lathe works. A CNC (Computer Numerical Control) lathe uses a computer to help you make very precise shapes. It follows exact commands, so it’s great for repeat work. On the other hand, a manual lathe needs you to turn knobs and move parts by hand. This lets you be more hands-on and creative, but it can be harder to repeat the same shape exactly.

What Are The Common Troubleshooting Steps For Issues That May Arise With A Metal Lathe Controller Board?If your metal lathe controller board isn’t working, here are some steps you can try. First, check the power supply to make sure it’s on and plugged in. Next, look for any loose wires; they might need to be connected tightly. Then, inspect the board for any signs of damage or burnt areas. Finally, if nothing works, ask a grown-up for help or check the user manual for more tips.

How Can Programming And Software Enhance The Performance Of A Metal Lathe Equipped With A Controller Board?Programming and software can make a metal lathe work better. You can control how fast it spins and how deep it cuts. This helps you create parts that are just right, with fewer mistakes. With good software, you can also save your work and repeat it easily. This makes your projects quicker and more precise!

What Safety Precautions Should Be Taken When Operating A Metal Lathe With A Computerized Controller Board?When using a metal lathe with a computer controller, we need to be very careful. Always wear safety glasses to protect your eyes. Keep long hair tied back and wear tight clothes so nothing gets caught. Make sure to keep hands away from moving parts. Finally, read the machine’s instructions before starting to understand how it works safely.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Application Guides And Metal Lathe Controller Boards:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a tool that helps shape metal into different forms. You can use it to make things like toys or parts for machines. A controller board is like the brain of the lathe; it tells the machine what to do. If you want to learn how to use a lathe, guides can help you understand the steps. Using these tools safely is very important, so always ask for help if you need it!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer, and I’ll be happy to help!”}},{“@type”: “Question”,”name”: “What Are The Key Features To Consider When Selecting A Controller Board For A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a controller board for a metal lathe, think about a few important things. First, make sure it has enough power to run your lathe. Second, check if it can connect with your computer easily. You also want a board that has good safety features. Lastly, see if it has options for upgrading in the future.”}},{“@type”: “Question”,”name”: “How Do Various Controller Board Types (Such As Cnc Vs. Manual) Affect The Operation Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different controller boards change how a metal lathe works. A CNC (Computer Numerical Control) lathe uses a computer to help you make very precise shapes. It follows exact commands, so it’s great for repeat work. On the other hand, a manual lathe needs you to turn knobs and move parts by hand. This lets you be more hands-on and creative, but it can be harder to repeat the same shape exactly.”}},{“@type”: “Question”,”name”: “What Are The Common Troubleshooting Steps For Issues That May Arise With A Metal Lathe Controller Board?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your metal lathe controller board isn’t working, here are some steps you can try. First, check the power supply to make sure it’s on and plugged in. Next, look for any loose wires; they might need to be connected tightly. Then, inspect the board for any signs of damage or burnt areas. Finally, if nothing works, ask a grown-up for help or check the user manual for more tips.”}},{“@type”: “Question”,”name”: “How Can Programming And Software Enhance The Performance Of A Metal Lathe Equipped With A Controller Board?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Programming and software can make a metal lathe work better. You can control how fast it spins and how deep it cuts. This helps you create parts that are just right, with fewer mistakes. With good software, you can also save your work and repeat it easily. This makes your projects quicker and more precise!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Operating A Metal Lathe With A Computerized Controller Board?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe with a computer controller, we need to be very careful. Always wear safety glasses to protect your eyes. Keep long hair tied back and wear tight clothes so nothing gets caught. Make sure to keep hands away from moving parts. Finally, read the machine’s instructions before starting to understand how it works safely.”}}]}