Have you ever watched a metal lathe in action? It’s like magic! A simple piece of metal transforms into a beautiful object. But there’s more to it than meets the eye. Understanding how to use a lathe is important to get the best results.

This guide will help you navigate the world of metal lathe cutting tools. Whether you are a beginner or an experienced user, knowing the right tools makes a difference. Did you know that the right tool can improve your project’s accuracy? Imagine finishing a project faster while getting excellent results!

We will explore different cutting tools and their specific applications. You’ll discover tips to choose the best tools for your lathe work. So, are you ready to enhance your skills? Let’s dive into the amazing world of lathe applications and metal cutting tools!

Lathe Application Guide: Metal Lathe Cutting Tools Explained

Lathe Application Guide for Metal Lathe Cutting Tools

Using a lathe can be exciting and very useful! This guide shares what you need to know about metal lathe cutting tools. It explains different types of tools and their special uses. Want to make precise cuts? Discover tips on tool selection and setup. Did you know that the right cutting tool can make your project smoother and faster? Learning these techniques can transform your metalworking skills into art!Understanding Metal Lathes

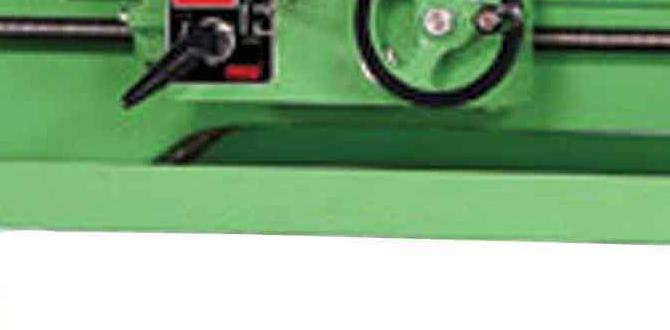

Definition and types of metal lathes. Key components and their functions.Metal lathes are powerful machines that help shape metal into useful things like tools and parts. There are different types, like engine lathes and CNC lathes, each with unique features for specific tasks. Key components include the bed, which supports everything; the spindle, where the metal goes; and the tailstock, which holds tools. It’s like a dance party for metal, where each part knows its moves!

| Component | Function |

|---|---|

| Bed | Supports and stabilizes the machine |

| Spindle | Holds rotating metal pieces |

| Tailstock | Holds additional tools and supports work |

Selecting the Right Cutting Tool

Factors to consider when choosing a cutting tool. Matching tools to specific applications.Selecting the right cutting tool is crucial for a metal lathe. Several factors can help you make the best choice:

- Material type: Consider if you are cutting steel, aluminum, or plastic.

- Tool shape: Different shapes suit various tasks, like facing or turning.

- Cutting speed: Some tools work better at high speeds; others need slower settings.

- Durability: Strong tools last longer and handle tough jobs.

Matching tools to specific tasks is also important. For example, use a sharp tool for precise cuts. A dull tool can ruin your work. Always pick the right tool for the job!

Why is tool selection so important?

Selecting the right cutting tool ensures precision, efficiency, and quality in your metalwork. It can also save time and reduce waste during projects.

Lathe Operations and Techniques

Common lathe operations (turning, facing, threading). Techniques for achieving precision and accuracy.Using a lathe can be both fun and rewarding. Common lathe operations include turning, where you shape the material into a cylinder, facing, which flattens the end of a piece, and threading, for making grooves that allow parts to screw together. To achieve precision, keep your tools sharp and measure twice. Remember, a dull tool is like trying to cut a sandwich with a spoon—nothing good comes from it!

| Operation | Description |

|---|---|

| Turning | Shaping material into a cylinder |

| Facing | Flattening the end of a workpiece |

| Threading | Creating grooves for screws |

Tool Setup and Maintenance

Steps for proper tool setup in lathe operations. Maintenance practices to extend tool life.Setting up your tools is like preparing for a dance; if you’re not ready, you might step on some toes—or worse, lose a finger! Start by checking tool sharpness. A dull tool is like a butter knife in a steak house—just not going to cut it. Next, ensure the tool’s height is right. Too high or too low could ruin your masterpiece.

Now, let’s chat about keeping those tools happy. A little maintenance goes a long way! Clean tools after each use like they’re your favorite pet. Lubricate them to keep things running smoothly—nobody likes a squeaky wheel, right? Here’s a nifty table for a quick maintenance checklist:

| Task | Frequency |

|---|---|

| Clean tools | After each use |

| Sharpen tools | As needed |

| Lubricate | Weekly |

Follow these steps, and your tools will serve you well! Remember, a well-maintained tool is a happy tool, and happy tools make for great projects. So, keep dancing with your lathe and show it some love!

Safety Precautions When Using Metal Lathes

Essential safety gear and equipment. Common hazards and how to mitigate them.Using metal lathes can be fun, but safety is super important! First, wear essential safety gear like goggles and gloves. These protect your eyes and hands from metal shavings and sharp tools. Here are some common hazards and ways to stay safe:

- Flying debris: Always wear goggles.

- Sharp tools: Use tools carefully and store them properly.

- Noise: Use ear protection to protect your hearing.

Always keep your workspace clean. This helps you avoid accidents. Remember, safety is the best way to enjoy your lathe projects!

What are the essential safety gear items for using a metal lathe?

Essential safety gear includes goggles, gloves, and ear protection. These items help keep you safe while working with metal lathes.Common Hazards and Safety Tips:

- Flying debris can harm your eyes.

- Sharp tools can cause cuts or injuries.

- Noise can damage your hearing over time.

Common Problems and Troubleshooting

Identifying issues with cutting tools and lathe operations. Solutions for common machining problems.Cutting tools and lathe operations can sometimes face issues. Identifying these problems is the first step to a better job. Some common signs include rough surfaces, unusual sounds, or parts not fitting right. Here are some easy solutions:

- Check tool sharpness. Dull tools can cause issues.

- Look for proper alignment. Misalignment leads to errors.

- Adjust speed settings. Too fast or slow can break tools.

- Keep everything clean. Dirt can cause malfunctions.

Fixing these problems can help your lathe run smoothly. Remember, attention to detail is key for success!

What are common issues with cutting tools?

Common issues with cutting tools include sharpness, alignment, and speed settings. These can lead to poor results. Keeping tools clean also helps maintain performance.

How can I troubleshoot lathe problems?

- Check tools for wear.

- Inspect workpieces for quality.

- Make adjustments as needed.

Case Studies and Practical Applications

Realworld examples of metal lathe applications. Lessons learned from industrial and hobbyist use.Many people use metal lathes for different jobs. For example, car makers create precise engine parts. Hobbyists often make cool gadgets and tools. One lesson learned is the importance of safety. Always wear protective gear! Each project teaches new skills. Here are some key points:

- Precision is key in professional settings.

- Practice improves technique for hobbyists.

- Safety gear is essential for all users.

What are some practical examples of using metal lathes?

In manufacturing, lathes make complex shapes for machines. Hobbyists use them for crafting unique designs. They can work on anything from furniture parts to art pieces.

Resources for Further Learning

Recommended books and online resources. Forums and communities for metalworking enthusiasts.Many great resources can help you learn more about metalworking. Here are some helpful suggestions:

- Books: Check out titles like “Metalworking: A Handbook” and “Lathe Work for Beginners.” These can give you solid tips.

- Online Resources: Websites like YouTube and WikiHow offer video tutorials that show many techniques.

- Forums: Join communities like Reddit’s Metalworking subreddit. You can ask questions and share ideas with other metal fans.

With these tools, you can improve your skills and have fun creating new projects!

What is a good starting book for metalworking?

A highly recommended book is “Metalworking: A Handbook.” It provides practical advice and clear instructions.

Where can I find online tutorials?

YouTube is an excellent source for video tutorials covering many metalworking techniques.

Conclusion

In summary, a lathe application guide helps you choose the right cutting tools for your metal projects. Knowing the types of tools and their uses can improve your skills and results. We encourage you to practice with different tools and explore more resources. With hands-on experience, you’ll become more confident in your metalworking journey. Happy machining!FAQs

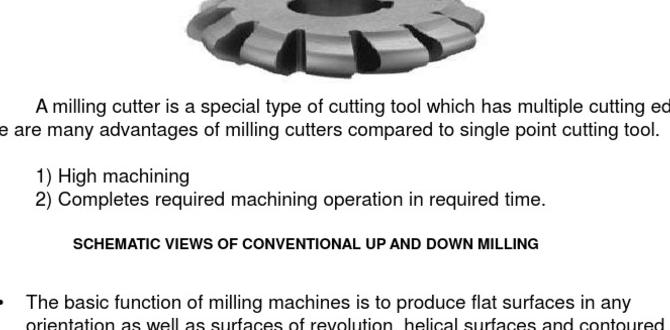

Sure! Here Are Five Related Questions On The Topic Of Metal Lathe Cutting Tools:Sure! Metal lathe cutting tools help shape metal into different forms. They can cut, shape, and smooth metal pieces. Some common tools are chisels, end mills, and drill bits. Each tool has a special job to do when working on metal. Using the right tool is important for a good finish!

Sure! Just give me the question, and I’ll provide a short and simple answer.

What Are The Different Types Of Cutting Tools Used With Metal Lathes And How Do They Vary In Their Applications?Metal lathes use different cutting tools to shape metal. Some common types are chisels, drills, and boring bars. Chisels cut straight lines and shapes. Drills make holes, while boring bars expand existing holes. Each tool has its job, helping us create different parts from metal.

How Do You Determine The Appropriate Cutting Tool Material For Specific Metalworking Projects?To pick the right cutting tool, you need to know what metal you’ll be working with. Some metals are soft, while others are hard. You also want a tool that stays sharp for a long time. Finally, think about how fast you need to cut. Once you have this information, you can choose the best tool for your project!

What Factors Should Be Considered When Selecting Cutting Tool Geometry For Turning Operations On A Metal Lathe?When choosing the cutting tool shape for turning metal, think about what you’re making. We need to consider the metal type and its hardness. Also, check the speed of the lathe and how deep we want to cut. The angle of the tool is important too; it helps make smooth cuts. Finally, remember the tool’s size to fit the lathe and workpiece.

How Do Tool Coatings Impact The Performance And Longevity Of Metal Lathe Cutting Tools?Tool coatings help cutting tools last longer and work better. They make the surface slippery, so it cuts smoothly. This reduces heat and wear, which means the tools stay sharp for a long time. When we use coated tools, we get better results and spend less time replacing them.

What Maintenance Practices Should Be Followed To Ensure Optimal Performance Of Metal Lathe Cutting Tools?To take care of metal lathe cutting tools, you should always keep them clean. Use a soft cloth to wipe off dust and chips. Check the tools for any damage, like dull edges or rust. Sharpen or replace them when needed. Finally, make sure to store them in a dry place to prevent rust.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Metal Lathe Cutting Tools:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Metal lathe cutting tools help shape metal into different forms. They can cut, shape, and smooth metal pieces. Some common tools are chisels, end mills, and drill bits. Each tool has a special job to do when working on metal. Using the right tool is important for a good finish!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just give me the question, and I’ll provide a short and simple answer.”}},{“@type”: “Question”,”name”: “What Are The Different Types Of Cutting Tools Used With Metal Lathes And How Do They Vary In Their Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes use different cutting tools to shape metal. Some common types are chisels, drills, and boring bars. Chisels cut straight lines and shapes. Drills make holes, while boring bars expand existing holes. Each tool has its job, helping us create different parts from metal.”}},{“@type”: “Question”,”name”: “How Do You Determine The Appropriate Cutting Tool Material For Specific Metalworking Projects?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To pick the right cutting tool, you need to know what metal you’ll be working with. Some metals are soft, while others are hard. You also want a tool that stays sharp for a long time. Finally, think about how fast you need to cut. Once you have this information, you can choose the best tool for your project!”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Selecting Cutting Tool Geometry For Turning Operations On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing the cutting tool shape for turning metal, think about what you’re making. We need to consider the metal type and its hardness. Also, check the speed of the lathe and how deep we want to cut. The angle of the tool is important too; it helps make smooth cuts. Finally, remember the tool’s size to fit the lathe and workpiece.”}},{“@type”: “Question”,”name”: “How Do Tool Coatings Impact The Performance And Longevity Of Metal Lathe Cutting Tools?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Tool coatings help cutting tools last longer and work better. They make the surface slippery, so it cuts smoothly. This reduces heat and wear, which means the tools stay sharp for a long time. When we use coated tools, we get better results and spend less time replacing them.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Followed To Ensure Optimal Performance Of Metal Lathe Cutting Tools?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To take care of metal lathe cutting tools, you should always keep them clean. Use a soft cloth to wipe off dust and chips. Check the tools for any damage, like dull edges or rust. Sharpen or replace them when needed. Finally, make sure to store them in a dry place to prevent rust.”}}]}