Have you ever wondered how machines create precise shapes from metal?

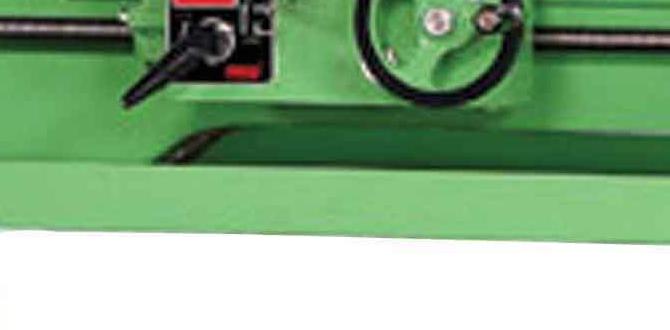

A lathe is one of those amazing tools. It spins metal while cutting away parts to form various shapes. But how does it work? That’s where the lathe application guide comes in.

In this guide, we will explore the metal lathe gear train. It’s a system that helps control the speed and movement of the lathe. Understanding this gear train lets you use a lathe more effectively.

Imagine crafting a perfect cylindrical shape with just a few adjustments. Wouldn’t that be cool?

Along the way, you will learn tips and tricks to get the best results. Have you ever tried to make something with a lathe? If so, you know how exciting it can be to see your ideas come to life! This guide will help you make that process even easier.

So, let’s dive into the fascinating world of lathes and gears. You might just discover a new hobby or skill that unleashes your creativity!

A Comprehensive Lathe Application Guide: Metal Lathe Gear Train

Lathe Application Guide: Metal Lathe Gear Train

Discover the fascinating world of metal lathes and their gear trains! A gear train helps control speed and torque, making it easier to shape metal. Imagine crafting a beautiful piece of art or a vital tool with just the right settings. Understanding the gear setup boosts your lathe’s performance. By adjusting gears, you can achieve different cutting speeds for various materials. Did you know that even small changes can make a big impact? Explore how gear trains turn your metalworking dreams into reality!Understanding the Basics of a Gear Train

Definition and function of a gear train in metal lathes. Key components and their roles in the gear train system.A gear train is a system of gears working together. It helps metal lathes turn smoothly. Each gear connects to another, passing movement from one to the next. This way, they make work easier. Let’s look at the key parts:

- Gears: These transfer power between parts.

- Axles: They hold the gears in place.

- Bearings: These allow the gears to spin freely.

- Drive Belt: This transfers motion to different parts.

By understanding how these parts fit together, you can appreciate how a metal lathe operates. The gear train makes cutting and shaping material smooth and efficient.

What are gear trains used for in metal lathes?

Gear trains in metal lathes control speed and torque. They allow precise movements. This is essential for crafting objects with accuracy.

Key functions of gear trains:

- Reduce speed: Slowing down the motor saves energy.

- Increase torque: Gives more power to cut tough materials.

Types of Gear Trains Used in Metal Lathes

Explanation of different gear train configurations: simple, compound, and differential. Pros and cons of each type for various machining tasks.Different gear trains are used in metal lathes to make cutting metal easier. Here are the main types:

- Simple Gear Train: It has a few gears in a straight line. It is easy to set up. However, it may not do all tasks well.

- Compound Gear Train: This type has multiple gears that work together. It offers more speed options but can be complex to use.

- Differential Gear Train: It allows for precise changes in speed. This is great for detailed work but can be tricky to maintain.

Each type has its own pluses and minuses for different jobs. Choose wisely based on your project needs!

What is a gear train in a metal lathe?

A gear train in a metal lathe is a system of interconnected gears. It helps control the speed and direction of the lathe. A good gear train leads to better cutting precision.

How do I choose the right gear train?

Choose based on your task: For simple tasks, a simple gear train works well. If you need speed, consider a compound train. For detail work, a differential train is best.

How Gear Trains Affect Lathe Performance

Impact of gear ratios on cutting speed and torque. Influence of material selection on gear train durability and efficiency.Gears play an important role in how lathes work. The gear ratio affects cutting speed and torque. A higher gear ratio means faster cutting but less torque. This is great for softer materials. If you need more power for hard materials, a lower gear ratio is better. Choosing strong materials for the gear train can also improve its durability. Stronger gears last longer and work better, helping your lathe perform its best every time.

How do gear ratios affect lathe performance?

Gear ratios influence both cutting speed and torque. If you want quick cuts, a higher ratio is helpful. For tougher materials, lower ratios offer more power.

Key Factors to Remember:

- High gear ratios: Faster cutting speed.

- Low gear ratios: More torque for tough materials.

- Material choice: Stronger gears last longer and increase efficiency.

Setting Up the Gear Train for Various Applications

Stepbystep guidelines for configuring gear trains for specific metalworking projects. Common setups for threading, turning, and milling applications.Setting up a gear train can seem tricky, but it’s easy with a few steps. First, choose the right gears for your project. For threading, use finer gears for precision. For turning, medium gears often work best. Lastly, milling benefits from gears that support higher speeds. Follow these simple steps:

- Identify your project type.

- Select the correct gear ratio.

- Assemble gears according to instructions.

- Test the setup before full use.

With practice, you’ll easily master any lathe application!

What are common gear train setups for metalworking?

Common setups include threading, turning, and milling. Each uses different gear ratios. Threading is for fine details. Turning shapes materials smoothly. Milling cuts into surfaces effectively.

Maintenance Best Practices for Gear Trains

Routine inspections and upkeep to ensure optimal performance. Troubleshooting common gear train issues in metal lathes.Keeping your gear train in top shape is important for a smooth-running metal lathe. Regular checks help spot problems early. Follow these simple tips:

- Check for unusual noises or vibrations.

- Inspect for wear or damage on gears.

- Ensure parts are lubricated properly.

- Look at connections for any play or looseness.

If you notice issues, act fast. Common problems include slipping gears or odd sounds. Fixing these early can save you time and money.

How do you maintain a gear train?

Performing simple inspections and ensuring lubrication can greatly enhance the gear train’s performance.

Conclusion

In conclusion, understanding a lathe’s gear train is crucial for your metalworking projects. You can adjust speeds and improve accuracy with the right setup. We encourage you to explore more about different gears and watch tutorial videos. By practicing regularly, you’ll become skilled at using a lathe effectively. Let’s get started and create something amazing!FAQs

Sure! Here Are Five Related Questions About Lathe Application And Gear Trains In Metal Lathes:Sure! A lathe is a machine that helps shape metal. You can use it to make things round or smooth. Gear trains are used in lathes to change how fast things turn. This helps you create different shapes easily. With these tools, we can build cool stuff!

Sure! Please provide the question you’d like me to answer.

What Are The Key Components Of A Metal Lathe’S Gear Train, And How Do They Function Together To Control Spindle Speed?A metal lathe uses a gear train to control how fast the spindle spins. The main parts are gears, levers, and belts. Gears work together to change the speed by turning one gear and making another move. When you pull a lever, it shifts the gears to the right spot. This helps you choose the speed you need for your work.

How Do Different Gear Ratios In A Lathe’S Gear Train Affect The Machining Process And The Finish Of The Workpiece?Different gear ratios in a lathe change how fast the spindle turns. A higher gear ratio makes the spindle turn slower, which helps create a smoother finish on the workpiece. If you use a lower gear ratio, the spindle spins faster, but it can make rougher surfaces. Choosing the right gear ratio helps you get the best result for your project. So, we need to pick the right gear ratio for the finish we want!

What Is The Significance Of Selecting The Appropriate Gear Train Configuration For Different Materials Being Machined On A Lathe?Choosing the right gear train for a lathe is really important. It helps us match the speed and power to the material we’re working with. For soft materials, we need a different setup than for hard ones. This way, we can cut better and avoid breaking tools. Making the right choice means better results and safer work!

How Can A Lathe Operator Troubleshoot Common Issues Related To The Gear Train, Such As Slipping Or Excessive Noise?To fix problems with the gear train, you can start by checking if it’s tight. If it’s loose, you can tighten the screws. You should also look for dirt or old grease that might make it noisy. Clean the parts and add new grease if needed. Lastly, listen for strange sounds, and if you hear anything odd, stop and inspect it closely.

What Are Some Common Modifications Or Upgrades That Can Be Made To A Lathe’S Gear Train To Improve Performance Or Versatility In Machining Operations?You can upgrade a lathe’s gear train in a few ways. First, adding more gears helps you cut different shapes and sizes. Second, using stronger gears makes the machine more durable and able to handle tough jobs. Lastly, you can install a variable speed drive to change the turning speed easily. These upgrades help you work better and create more cool projects!