Have you ever wondered how metal parts are made? A lathe helps us transform raw metal into precise shapes. One key component of a lathe is the handwheel. This small tool plays a big role in controlling the machine.

Using a metal lathe can seem tricky at first. But with the right guidance, you can master it. The handwheel allows you to move the tool smoothly. It gives you control over the cut, making precision easier.

Imagine crafting a perfect piece for your project. Each turn of the handwheel brings you closer to your goal. Learning the best lathe applications can make all the difference in your work!

Did you know that lathes have been used for thousands of years? They started as simple tools and became complex machines. Today, they help builders, artists, and inventors alike. So join us as we explore the best practices for using a metal lathe handwheel!

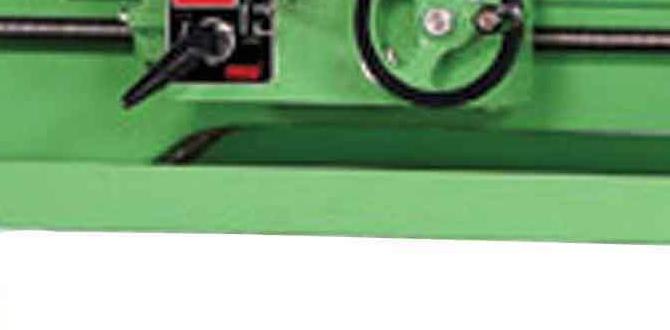

Lathe Application Guide: Metal Lathe Handwheel Explained Introduction Lathe Machines Are Vital Tools In Machining Industries, Allowing For The Creation Of Precise Components Through Various Cutting And Shaping Processes. One Specific Aspect Of These Machines That Contributes Significantly To Their Functionality And Ease Of Operation Is The Handwheel. This Guide Aims To Provide Insight Into The Applications Of A Metal Lathe Handwheel And How It Enhances Lathe Operations. Understanding The Metal Lathe Handwheel A Metal Lathe Handwheel Is A Crucial Component That Allows The Operator To Manually Adjust The Positioning Of The Workpiece Or The Cutting Tool. It Is Usually Mounted On The Lathe’S Cross Slide Or Tailstock. Understanding Its Function Is Essential For Both Beginners And Seasoned Machinists. Key Applications Of The Handwheel 1. **Precision Movement**: The Handwheel Provides Smooth And Fine Adjustments, Allowing For Precise Movements In Both The Longitudinal And Transverse Directions. This Is Particularly Useful When The Operator Needs To Make Minute Changes During The Machining Process. 2. **Manual Control**: While Cnc Lathes Offer Automated Solutions, The Handwheel Allows For Manual Control, Giving Operators Flexibility To Work On Complex Or Unique Projects. This Is Especially Beneficial In Settings Where Small Batches Or Customized Pieces Are Produced. 3. **Testing And Calibration**: Before A Project Begins, The Handwheel Can Be Used To Calibrate The Machine Settings. Operators Can Manually Adjust The Tool’S Position To Ensure The Correct Alignment, Which Is Critical For Achieving The Desired Finish. 4. **Emergency Operations**: In Cases Where Automated Controls May Fail, The Handwheel Allows Operators To Continue Working Manually, Ensuring That Productivity Is Maintained, And Tasks Can Be Completed Without Interruption. Best Practices For Using The Handwheel – **Calibrate Regularly**: Ensure The Lathe Is Calibrated For Accurate Adjustments. Regular Checks Can Prevent Drift In Machining Accuracy. – **Use Appropriate Force**: Apply Even Pressure While Turning The Handwheel To Maintain Smoothness And Prevent Jamming Or Damages To The Machine. – **Maintain Cleanliness**: Keep The Handwheel And Surrounding Area Clean. Debris Can Lead To Mechanical Issues Or Inaccuracies During Operation. Conclusion The Metal Lathe Handwheel Is More Than Just A Manual Control Tool; It Is An Essential Component That Enhances The Overall Functionality Of A Lathe Machine. Understanding Its Applications And Following Best Practices Can Greatly Improve Precision And Efficiency In Machining Tasks. Whether You Are A Newcomer To The World Of Metalworking Or An Expert Machinist, Mastering The Use Of The Handwheel Can Significantly Elevate Your Crafting Skills.

Lathe Application Guide: Metal Lathe Handwheel

Discover the importance of the metal lathe handwheel in machining. This simple tool helps you make precise adjustments with ease. Imagine shaping a piece of metal smoothly, just by turning a wheel! The handwheel allows for better control, resulting in cleaner cuts. Did you know that mastering this feature can elevate your projects? Whether you’re a beginner or seasoned pro, understanding the handwheel is key to effective lathe use.Understanding Metal Lathes

Definition and core functions of a metal lathe. Common components and their roles in machining.A metal lathe is a machine that shapes metal. It spins a piece of metal while cutting tools reshape it. This process is essential for making parts for tools, cars, and other items. Key components include:

- Bed: The sturdy base that supports the lathe.

- Headstock: Holds the spinning tool and motor.

- Tailstock: Supports the other end of the metal piece.

- Carriage: Moves the cutting tool along the metal.

- Handwheel: Provides manual control for precise positioning.

These parts work together to create smooth and accurate shapes in metal. This makes metal lathes very valuable in machining and manufacturing. Knowing these basics can help anyone understand how metal lathes function.

What are the main uses of a metal lathe?

The main uses of a metal lathe include shaping, drilling, and creating cylindrical parts. They help in making items like screws, gears, and even artistic sculptures.

The Importance of Handwheels in Lathe Operations

Role of handwheels in precision control. Comparison of handwheel functionality versus digital controls.Handwheels are like the steering wheel of a lathe. They help you guide your project with precision. With a handwheel, you can make tiny, careful adjustments to the machine. This is great for creating smooth cuts. In comparison, digital controls might seem fancy, but they can be tricky. Sometimes, turning a knob feels easier than pressing buttons. Plus, you can’t accidentally reset the handwheel while sneezing!

| Aspect | Handwheel | Digital Control |

|---|---|---|

| Precision | High | Medium |

| User Control | Direct | Indirect |

| Ease of Use | Simple | Complex |

Overall, handwheels provide a more personal touch. They put the operator in charge. So, while both methods work, handwheels are often the favorite choice for skilled workers.

Setting Up a Metal Lathe Handwheel

Stepbystep guide to installing handwheels on a lathe. Tips for aligning the handwheel for optimal performance.Installing a metal lathe handwheel is simple. Follow these steps for smooth operation:

- Gather your tools: You will need a socket wrench and a screwdriver.

- Remove the old handwheel: Loosen screws and pull the handwheel off.

- Position the new handwheel: Align it carefully on the shaft.

- Secure it: Tighten all screws firmly but not too tight.

- Test it: Spin the handwheel to ensure smooth movement.

For best performance, align the handwheel directly with the machine’s center. This helps in achieving precise cuts and enhances the lathe’s efficiency. A well-aligned handwheel can make all the difference in your projects!

How do I align the handwheel correctly?

To align the handwheel accurately, make sure it sits level with the lathe’s spindle. Use a ruler to check for gaps. Adjust as needed for a perfect fit.

Techniques for Effective Use of Handwheels

Best practices for manual operations using handwheels. Techniques for enhancing productivity and accuracy.Using handwheels on a metal lathe can increase both speed and precision. To make the most of these handy tools, always keep your hand on the wheel. This helps with accuracy and feels like you are in control—like a boss! For better productivity, try to work slowly and steadily. Rushing can lead to mistakes or worse, a wobbly project. Remember, a steady hand can turn average work into something amazing! Here’s a quick tip table for you:

| Technique | Description |

|---|---|

| Focus | Stay attentive to the process. |

| Consistency | Move the handwheel steadily. |

| Practice | Regular use leads to better skills. |

With practice, handling the handwheel will feel as easy as pie! Keep these tips in mind, and you’ll be working like a pro in no time.

Common Issues and Troubleshooting Handwheel Problems

Identification of frequent problems faced with handwheels. Solutions and maintenance tips for troubleshooting.Handwheels are important parts of a lathe, but they can have problems. Some common issues are:

- Sticking or not turning smoothly

- Loose handle causing lack of control

- Inaccurate measurements

To troubleshoot these problems, try these tips:

- Clean the handwheel with oil.

- Tighten any loose screws.

- Replace worn-out parts as needed.

Regular maintenance can keep your handwheel working well. Remember to check it often!

What should I do if my handwheel is stuck?

If your handwheel is stuck, try cleaning it with some oil. This can help it move smoothly again.

Upgrading Handwheels for Enhanced Performance

When to consider upgrading your lathe handwheel. Features to look for in advanced handwheel models.Upgrading the lathe handwheel can be a game-changer. If you feel your current handwheel is giving you more trouble than your pet cat at dinner time, it might be time for an upgrade. Look for models that offer smoother rotation, better grip, and even customizable sizes. These features can make your work not only easier but also way more enjoyable. Why wrestle with a stubborn wheel when you can glide through your projects like a pro?

| Feature | Benefits |

|---|---|

| Smoother Rotation | Less effort needed, more precision. |

| Better Grip | No more slippage, keep your hands happy! |

| Customizable Sizes | Fit it just right for your unique projects. |

In short, a handwheel upgrade can save you time and effort. And who doesn’t want more time for snacks in the workshop?

Safety Measures When Using Handwheels

Key safety protocols to follow during operation. Common safety hazards associated with manual lathing.Using handwheels safely is key to avoiding accidents. First, always wear protective goggles to shield your eyes from debris. Keep loose clothing and hair away from the machine, as they love to snack on them! Always check that the area is clear before you start turning—no one wants a surprise visitor. Remember, the biggest threat is usually your own carelessness. Follow these safety protocols and your lathe will be a lot less scary!

| Safety Protocol | Description |

|---|---|

| Wear Protective Gear | Use goggles and gloves to prevent injuries. |

| Check the Area | Ensure no one is too close before operating. |

| Secure Loose Items | Keep clothing and hair away from moving parts. |

Case Studies: Real-World Applications of Metal Lathe Handwheels

Examples of industries that rely on lathe handwheels. Analysis of successful projects utilizing handwheel techniques.Many industries depend on metal lathe handwheels to create incredible products. For example, the automotive industry uses them to shape engine parts. This ensures that everything fits just right. Additionally, the aerospace industry finds handwheels helpful in crafting lightweight components that keep planes in the sky. In a recent project, a workshop enhanced its efficiency by adjusting handwheel settings, resulting in a 30% improvement in production speed. Talk about a job well done!

| Industry | Application |

|---|---|

| Automotive | Shaping engine parts |

| Aerospace | Crafting lightweight components |

| Manufacturing | Creating precise tools |

Conclusion

In conclusion, a lathe application guide helps you understand how to use a metal lathe effectively. The handwheel controls movement and precision in your projects. By practicing with the lathe and referring to guides, you can improve your skills. Explore more resources to deepen your knowledge. Remember, every practice session brings you closer to mastering this handy tool!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Applications And Handwheels:Sure! A lathe is a machine that helps us shape materials like wood or metal. We can use it to create things like toys, furniture, and car parts. A handwheel is a round handle that lets you easily move or adjust the lathe while it’s working. By turning the handwheel, you make changes to the shape or size of what you’re building. It helps us work carefully and make things just right!

Sure! Please provide the question you would like me to answer.

What Are The Primary Functions Of The Handwheel On A Metal Lathe?The handwheel on a metal lathe helps us move the tool closer or farther from the metal we are shaping. It lets you control how much metal you cut at a time. You can also use it to adjust the position of the metal piece you are working on. This helps make sure everything is even and smooth.

How Can An Operator Effectively Use The Handwheel For Accurate Feed Adjustments During Machining Operations?To use the handwheel for accurate feed adjustments, first, make sure the machine is off. Then, turn the handwheel slowly. This helps you move the tool up or down carefully. Check the measurements frequently to make sure it’s right. Practice makes you better at using the handwheel.

What Maintenance Practices Should Be Performed On The Handwheel Assembly Of A Metal Lathe To Ensure Smooth Operation?To keep the handwheel assembly of a metal lathe working well, you should regularly clean it. Dust and dirt can slow it down. You can also check for loose parts and tighten them if needed. Finally, applying some oil helps it move smoothly. Doing these steps will make sure your lathe works nicely!

How Does The Design Of The Handwheel Impact The Precision And Ergonomics Of A Metal Lathe Operation?The handwheel on a metal lathe helps you turn the machine easily. If it’s designed well, you can make small, exact movements. This means your work will be more precise. A good handwheel also feels comfortable in your hand, so you won’t get tired. When you feel good using it, you do a better job!

What Safety Precautions Should Be Considered When Operating The Handwheel On A Metal Lathe?When using the handwheel on a metal lathe, you should always keep your hands clear of moving parts. Make sure your clothes are tight and don’t hang down. Never rush or be distracted while working. It’s also smart to wear safety goggles to protect your eyes. Lastly, make sure you know how to stop the machine quickly if needed.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Applications And Handwheels:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that helps us shape materials like wood or metal. We can use it to create things like toys, furniture, and car parts. A handwheel is a round handle that lets you easily move or adjust the lathe while it’s working. By turning the handwheel, you make changes to the shape or size of what you’re building. It helps us work carefully and make things just right!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Primary Functions Of The Handwheel On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The handwheel on a metal lathe helps us move the tool closer or farther from the metal we are shaping. It lets you control how much metal you cut at a time. You can also use it to adjust the position of the metal piece you are working on. This helps make sure everything is even and smooth.”}},{“@type”: “Question”,”name”: “How Can An Operator Effectively Use The Handwheel For Accurate Feed Adjustments During Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To use the handwheel for accurate feed adjustments, first, make sure the machine is off. Then, turn the handwheel slowly. This helps you move the tool up or down carefully. Check the measurements frequently to make sure it’s right. Practice makes you better at using the handwheel.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Performed On The Handwheel Assembly Of A Metal Lathe To Ensure Smooth Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the handwheel assembly of a metal lathe working well, you should regularly clean it. Dust and dirt can slow it down. You can also check for loose parts and tighten them if needed. Finally, applying some oil helps it move smoothly. Doing these steps will make sure your lathe works nicely!”}},{“@type”: “Question”,”name”: “How Does The Design Of The Handwheel Impact The Precision And Ergonomics Of A Metal Lathe Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The handwheel on a metal lathe helps you turn the machine easily. If it’s designed well, you can make small, exact movements. This means your work will be more precise. A good handwheel also feels comfortable in your hand, so you won’t get tired. When you feel good using it, you do a better job!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Considered When Operating The Handwheel On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using the handwheel on a metal lathe, you should always keep your hands clear of moving parts. Make sure your clothes are tight and don’t hang down. Never rush or be distracted while working. It’s also smart to wear safety goggles to protect your eyes. Lastly, make sure you know how to stop the machine quickly if needed.”}}]}