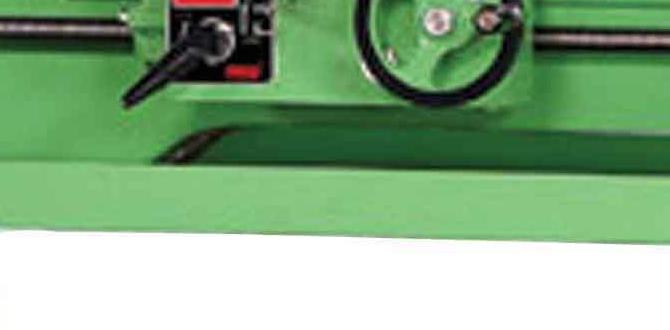

Have you ever seen a metal lathe in action? It’s fascinating to watch! A lathe is a powerful tool that shapes metal into various forms. Many people use it in workshops, factories, and even at home.

But how does it work? It might seem complicated at first. However, with a little guidance, anyone can learn the basics. Whether you’re a beginner or someone looking to refine your skills, this lathe application guide is for you.

This guide covers everything about metal lathe operations. You will discover tips, tricks, and techniques to enhance your projects. Did you know that even ancient craftsmen used simple lathes to create beautiful objects? Lathes have a rich history!

Join us on this journey. By the end, you’ll feel confident and ready to tackle any metal project. Let’s explore the exciting world of metal lathe operations together!

Lathe Application Guide: Mastering Metal Lathe Operations

Lathe Application Guide for Metal Lathe Operations

A lathe is a powerful tool for shaping metal. This guide covers essential metal lathe operations. Users learn how to set up their lathes correctly and choose the right tools. Did you know that a lathe can create both simple and complex shapes? Understanding speeds and feeds can help improve accuracy. Safety tips are also highlighted for a worry-free experience. Dive in to discover how to master your metal lathe and create amazing projects!Essential Lathe Operations

Basic turning, facing, and drilling techniques. Advanced operations: threading and taper turning.Lathe operations are like magic tricks in metalworking! First, we have basic turning, where we shape metal into round pieces. It’s like making a giant pencil! Then, there’s facing, which flattens a surface—perfect for making a smooth table for your family’s cookie jar. Drilling is next, and it’s just like making a hole in the ground, but much cooler.

Now let’s get fancy with advanced jobs! Threading adds grooves for screws, so nothing falls apart, literally. And taper turning shapes a piece like a pencil point or a witch’s hat. Remember, using a lathe is like squeezing toothpaste—be careful not to make a mess!

| Operation | Description |

|---|---|

| Basic Turning | Shaping metal into a cylindrical form |

| Facing | Flattening the end surface of a workpiece |

| Drilling | Creating holes in metal parts |

| Threading | Making helical grooves for screws |

| Taper Turning | Shaping one end narrower than the other |

So, whether you’re turning, facing, or drilling, the lathe is your trusty sidekick in the metal world!

Choosing the Right Metal Lathe

Factors to consider: size, power, and versatility. Comparing manual vs. CNC lathes.Picking a metal lathe is like choosing a new pet; you want one that fits your needs! First, think about size. Smaller lathes take up less space but might limit your projects. Then there’s power; stronger lathes can handle tougher materials. Lastly, consider versatility. A flexible lathe can do many tasks, making it your best buddy!

Now, should you go for manual or CNC lathes? Manual lathes can feel like driving a stick shift, giving you hands-on control. But if you want to sit back and let technology do the work, CNC lathes are the way to go. They’re like having a robot on your team. Below is a small comparison:

| Feature | Manual Lathe | CNC Lathe |

|---|---|---|

| Control | Hands-on | Automated |

| Learning Curve | Steep | Gentle |

| Cost | Lower | Higher |

Whether you like them manual or fancy, choosing the right lathe can make your projects turn out *just* right—like a perfectly cooked pancake! So think wisely!

Safety Practices in Metal Lathe Operations

Personal protective equipment (PPE) requirements. Common safety hazards and prevention measures.Working safely with metal lathes is crucial. Always wear personal protective equipment (PPE) like goggles, gloves, and steel-toed shoes. This gear helps protect you from chips and sharp parts that can fly at you faster than a squirrel on a caffeine rush! Common safety hazards include getting caught in moving parts or tools. To prevent accidents, keep your workspace tidy. Remember, a clean shop is a happy shop! Here’s a handy table for quick reference:

| Safety Gear | Hazard Type | Prevention Tip |

|---|---|---|

| Goggles | Flying debris | Always wear them! |

| Gloves | Moving parts | Use cut-resistant gloves. |

| Steel-toed shoes | Heavy objects | Avoid toe accidents! |

Maintenance for Longevity and Performance

Daily, weekly, and monthly maintenance tasks. Troubleshooting common lathe issues.Keeping your lathe happy is like keeping a pet—feed it well, and it’ll be your best buddy! Regular checks are key to avoid a meltdown, like a toddler who missed nap time. Daily tasks include wiping away dust and checking the oil. Weekly tasks? Check belts and alignment. Monthly maintenance lets you clean cam followers and bearings. If things go wrong, like strange noises or wobbly parts, look closely! You might find a loose screw or an old belt needing replacement. Here’s a handy table for quick reference:

| Maintenance Task | Frequency |

|---|---|

| Dust and Debris Check | Daily |

| Oil Levels | Daily |

| Belts and Alignment Check | Weekly |

| Cam Followers and Bearings Clean | Monthly |

Tips and Tricks for Optimal Lathe Performance

Techniques for improving precision and finish quality. Setting up the workpiece for maximum efficiency.To boost your lathe’s performance, focus on precision and finish quality. A clean workpiece is essential for a smooth finish. Use sharp tools; dull tools are like a dog trying to catch its tail—lots of effort, but no success! When setting up, position the workpiece snugly and center it well to avoid wobbles. Remember, precision leads to that shiny, impressive result you want!

| Tip | Description |

|---|---|

| Use Sharp Tools | They cut better and produce cleaner finishes. |

| Clean the Workpiece | A clean start leads to great results! |

| Center Your Workpiece | This minimizes vibrations and improves accuracy. |

Remember, “A smooth lathe makes for a smooth journey.” Happy turning!

Common Applications of Metal Lathes

Industries utilizing metal lathes: aerospace, automotive, and manufacturing. Examples of projects suitable for metal lathe operations.Metal lathes serve important functions in many industries. They are widely used in aerospace, automotive, and manufacturing. Each industry benefits in different ways. These machines help create precise parts like:

- Engine components for cars

- Small parts for airplanes

- Tools and fixtures for factories

With a metal lathe, workers can turn raw metal into the final pieces they need. This technology makes production easier and more accurate.

What are some projects suitable for metal lathe operations?

Many projects are great for metal lathe operations. Some examples include:

- Custom shafts

- Gear parts

- Different types of brackets

These projects show how lathes are helpful tools in various fields.

Exploring Innovations in Metal Lathe Technology

Recent advancements in lathe technology. Future trends shaping metal lathe operations.Metal lathe technology is changing faster than a cat on a hot tin roof! Recent advancements have introduced smart sensors and automation, making operations smoother. These updates allow precise cuts and speed up projects, so you can be a metal wizard in no time. The future? Think even sleeker designs and greener machines. It’s like your lathe got a makeover and a new gym membership!

| Advancements | Future Trends |

|---|---|

| Smart Sensors | Eco-Friendly Machines |

| Automation | Sleeker Designs |

| Precision Cutting | Increased Efficiency |

Conclusion

In summary, a lathe is a powerful tool for shaping metal. You can create precise parts through careful operation. Remember to follow safety guidelines and practice regularly. Explore different techniques to improve your skills. For more details, check out a comprehensive lathe application guide. With time and practice, you’ll become a skilled metalworker!FAQs

What Are The Fundamental Techniques Involved In Setting Up A Metal Lathe For Precision Machining Operations?To set up a metal lathe, we first make sure the machine is clean and safe. Then, we choose the right tools for the job. Next, we adjust the tool so it lines up perfectly with the metal piece. After that, we carefully set the speed and feed rate to match the material. Finally, we check everything again before starting to work to ensure our piece will turn out just right.

How Can Different Cutting Tools And Tool Geometries Affect The Quality And Finish Of The Workpiece During Lathe Operations?Different cutting tools and their shapes can change how the workpiece looks. A sharp tool cuts cleanly, making a smooth finish. On the other hand, a dull tool can leave rough spots. The shape of the tool also matters; some shapes are better for rounding edges, while others are good for straight cuts. Using the right tool helps you make better, nicer pieces.

What Safety Precautions Should Be Taken When Operating A Metal Lathe To Prevent Accidents And Ensure A Safe Working Environment?When using a metal lathe, always wear safety goggles to protect your eyes. Keep your hair tied back and wear snug clothing to avoid getting caught in the machine. Make sure the area around you is clean and free of clutter. Always follow the machine’s rules, and never reach into the lathe while it’s running. Lastly, ask for help if you’re unsure about something.

How Do You Determine The Appropriate Feed Rate And Spindle Speed For Various Materials When Using A Metal Lathe?To find the right feed rate and spindle speed for different metals, you start by checking their hardness. Softer metals go faster, while harder ones go slower. You can also look up guidelines in a chart or manual. Each material has its own best settings to make sure you get a smooth finish. Always remember to test and adjust if needed!

What Maintenance Practices Are Essential For Ensuring The Longevity And Performance Of A Metal Lathe In A Workshop?To keep a metal lathe working well, you need to clean it regularly. Make sure to remove dust and chips after each use. Check the oil levels and add oil where needed to keep parts moving smoothly. Tighten any loose screws and parts so everything stays in place. Finally, give your lathe a good inspection every few months to catch any problems early.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Fundamental Techniques Involved In Setting Up A Metal Lathe For Precision Machining Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe, we first make sure the machine is clean and safe. Then, we choose the right tools for the job. Next, we adjust the tool so it lines up perfectly with the metal piece. After that, we carefully set the speed and feed rate to match the material. Finally, we check everything again before starting to work to ensure our piece will turn out just right.”}},{“@type”: “Question”,”name”: “How Can Different Cutting Tools And Tool Geometries Affect The Quality And Finish Of The Workpiece During Lathe Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different cutting tools and their shapes can change how the workpiece looks. A sharp tool cuts cleanly, making a smooth finish. On the other hand, a dull tool can leave rough spots. The shape of the tool also matters; some shapes are better for rounding edges, while others are good for straight cuts. Using the right tool helps you make better, nicer pieces.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Operating A Metal Lathe To Prevent Accidents And Ensure A Safe Working Environment? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, always wear safety goggles to protect your eyes. Keep your hair tied back and wear snug clothing to avoid getting caught in the machine. Make sure the area around you is clean and free of clutter. Always follow the machine’s rules, and never reach into the lathe while it’s running. Lastly, ask for help if you’re unsure about something.”}},{“@type”: “Question”,”name”: “How Do You Determine The Appropriate Feed Rate And Spindle Speed For Various Materials When Using A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right feed rate and spindle speed for different metals, you start by checking their hardness. Softer metals go faster, while harder ones go slower. You can also look up guidelines in a chart or manual. Each material has its own best settings to make sure you get a smooth finish. Always remember to test and adjust if needed!”}},{“@type”: “Question”,”name”: “What Maintenance Practices Are Essential For Ensuring The Longevity And Performance Of A Metal Lathe In A Workshop? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a metal lathe working well, you need to clean it regularly. Make sure to remove dust and chips after each use. Check the oil levels and add oil where needed to keep parts moving smoothly. Tighten any loose screws and parts so everything stays in place. Finally, give your lathe a good inspection every few months to catch any problems early.”}}]}