Have you ever wondered how parts of a machine come together to create magic? Imagine a metal lathe, spinning at high speeds, shaping metal into useful parts. A lathe application guide helps you understand this process better. It shows you how to use metal lathe parts effectively.

Using a lathe can be exciting and a bit tricky. Picture yourself in a workshop filled with tools and machines. You’re ready to craft, but you need to know what each part does. What if I told you that each small piece of a lathe plays a big role in making your project succeed?

For instance, did you know the tailstock helps hold pieces steady while you work? It’s true! Each part, from the tool post to the carriage, has a special job. This guide will take you on a journey through the world of lathe applications. Get ready to discover how each metal lathe part works together to create amazing results.

Lathe Application Guide: Metal Lathe Parts Explained

Lathe Application Guide: Understanding Metal Lathe Parts

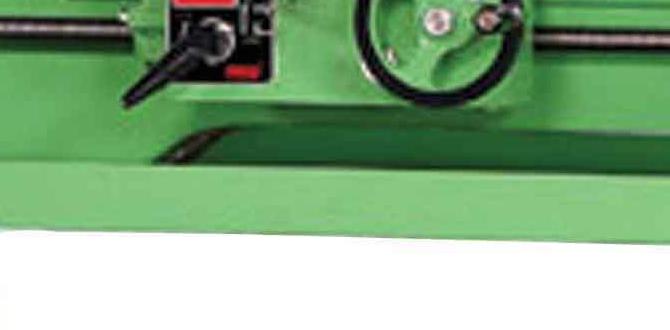

Metal lathes are essential for crafting precise components in various projects. This guide explores key metal lathe parts, like the bed, spindle, and tailstock. Each part plays a crucial role in how the lathe works. Did you know that the spindle spins faster than your bike wheel? Knowing these parts helps you better operate a lathe and complete tasks efficiently. Want to improve your skills? Understanding these metal lathe parts is the first step!Understanding Metal Lathes

Definition and purpose of metal lathes. Types of metal lathes and their unique features.Metal lathes are machines that shape metal into different forms. They spin metal pieces and use cutting tools to create shapes like cylinders or cones. These machines help make parts for cars, airplanes, and tools.

There are several types of metal lathes, each with special features:

- Engine Lathe: Useful for general purposes, it’s easy to operate.

- CNC Lathe: This type uses computers for more precise work.

- Toolroom Lathe: Great for small projects, it allows for detailed work.

- Turret Lathe: Ideal for making many identical parts fast.

Understanding these machines can help you see their importance in many industries.

What is the purpose of a metal lathe?

The purpose of a metal lathe is to shape and cut metal into specific designs for various uses. They help create parts that are strong and accurate.

Lathe Tooling and Accessories

Types of tools used in metal lathes. Importance of proper tooling for effective machining.Metal lathes use special tools to shape materials. Each tool has a different job. Common tools include:

- Cutting tools: These cut metal into the right shapes.

- Drill bits: They make holes in the metal.

- Tool holders: These keep the tools steady while working.

Using the right tooling is super important. It helps make smooth and precise cuts. Without proper tools, the work can become messy. Happy machining means using the best tools!

What tools are essential for lathe work?

Essential tools for lathe work include cutting tools, drill bits, and tool holders. These tools help create accurate shapes and holes in the metal.

Setting Up Your Metal Lathe

Stepbystep setup process for beginners. Common mistakes to avoid during setup.Setting up a metal lathe can be a fun adventure! First, make sure you have a clean workspace. Grab your tools and the manual—yes, those little pieces of paper that seem boring but are actually super helpful. Follow these simple steps:

| Steps | Description |

|---|---|

| 1. Check parts | Ensure all parts are present and not broken. |

| 2. Level the lathe | Use a spirit level to avoid wobbly work. |

| 3. Attach tools | Secure all tools and accessories tightly. |

Common mistakes include overlooking the level and forgetting safety gear. Remember, a level lathe is a happy lathe! Take it slow, and if your lathe seems to be shaking like it’s dancing, you might want to double-check those screws. Happy turning!

Common Applications of Metal Lathes

Various industries utilizing metal lathes. Examples of projects and parts typically produced.Many industries use metal lathes to create parts. They help make items that we see every day. Here are some common examples:

- Automotive industry: Parts like gears and shafts.

- Aerospace sector: Components for airplanes, such as brackets.

- Manufacturing: Tools and fixtures for machines.

- Furniture design: Wooden legs or fittings.

These lathes are essential for making precise parts. They ensure that everything fits and works well together.

What projects use metal lathes?

Metal lathes are used for many projects! They create items like metal rods, cylinders, and custom tools. Each project benefits from the accuracy that metal lathes provide.

Maintenance and Safety Tips for Metal Lathes

Regular maintenance practices to ensure durability. Safety precautions to follow while operating a lathe.To keep your metal lathe in top shape, regular maintenance is key. Clean it often to avoid dirt build-up. Lubricate parts as needed—like giving your lathe a nice oil massage! Check for wear and tear, and replace worn parts quickly; nobody likes a grumpy lathe. Safety is also vital. Always wear goggles and gloves. Never wear loose clothing—trust me, your sleeves don’t want to become part of the lathe!

| Maintenance Tips | Safety Precautions |

|---|---|

| Clean regularly | Wear goggles |

| Lubricate parts | Use gloves |

| Check for wear | Secure clothing |

| Replace worn parts | Stay alert |

Remember, a happy lathe makes for happy projects! Keep these tips in mind, and you’ll whip out those metal parts like a pro.

Troubleshooting Common Lathe Problems

Identifying and resolving frequent issues. Tips for optimizing performance and efficiency.Lathe problems can slow down your work. It’s good to know how to spot and fix them. Common issues include poor cuts, strange noises, and overheating. Here are some tips for better lathe performance:

- Check and tighten all parts regularly.

- Keep the lathe clean from dust and debris.

- Use the right tools for your projects.

- Adjust speeds based on material type.

By following these tips, you can keep your lathe running smoothly and efficiently!

How can I fix my lathe if it makes weird noises?

Check for loose parts or unusual friction. Tighten any loose components and apply lubricant where needed.

What can I do to stop my lathe from overheating?

Make sure to use proper speeds and take breaks. This will help cool the machine down during use.

Conclusion

In conclusion, understanding metal lathe parts is essential for effective lathe applications. You learn how each part functions to create precise shapes. We encourage you to explore more about lathe techniques and safety tips. With practice, you can master these tools. Check out a beginner’s guide or watch a tutorial to get started on your metalworking journey!FAQs

Here Are Five Related Questions On The Topic Of Lathe Application Guide For Metal Lathe Parts:Sure! A lathe is a machine that spins metal to shape it. You can use it to make parts for machines or tools. When using a lathe, you should always wear safety gear like goggles. Follow the guide carefully to avoid mistakes. Remember, practice helps you get better!

Sure! Please provide the question you’d like me to answer.

What Are The Essential Components Of A Metal Lathe And Their Specific Functions In The Machining Process?A metal lathe has several important parts. The bed is the base that holds everything steady. The headstock spins the metal piece, while the tailstock helps support it. The carriage moves tools to cut the metal into the right shape. Lastly, the tool post holds the cutting tool in place. Together, they help us create shapes from metal!

How Do You Properly Set Up And Align A Metal Lathe For Precision Turning Of Metal Parts?To set up a metal lathe, first, make sure it’s on a flat surface. Next, check that the tailstock and headstock are lined up straight. You can use a ruler or a straight edge for this. Then, secure the metal part in the lathe’s chuck, which holds it steady. Finally, adjust the speed and feed rate to get a smooth cut when you start turning. Always wear safety gear to protect yourself while working.

What Is The Difference Between Various Types Of Cutting Tools Used On A Metal Lathe, And How Do You Select The Right Tool For A Specific Application?Different cutting tools on a metal lathe have special shapes and sizes. Some tools are good for shaping, while others are best for cutting. To choose the right tool, think about what you want to do. If you need to make a smooth finish, pick a finishing tool. If you want to remove a lot of metal fast, use a roughing tool.

What Safety Precautions Should Be Taken When Operating A Metal Lathe To Prevent Accidents And Ensure Proper Handling Of Workpieces?When using a metal lathe, you should always wear safety goggles to protect your eyes. Keep your hair tied back and wear tight-fitting clothes to avoid getting caught in the machine. Make sure to keep your hands away from moving parts. Always check that your workpiece is secure before starting the lathe. Lastly, know where the emergency switch is, so you can stop the machine quickly if needed.

How Can The Use Of Different Machining Techniques, Such As Facing, Turning, And Threading, Enhance The Capabilities Of A Metal Lathe In Metalworking Applications?Using different machining techniques on a metal lathe helps us make many shapes and sizes of metal parts. Facing lets us make flat surfaces, which is important for fitting pieces together. Turning helps us shape the metal into round forms, like cylinders. Threading creates grooves, which are needed for screws and bolts. By using these techniques, we can create stronger and more useful metal items.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Application Guide For Metal Lathe Parts:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that spins metal to shape it. You can use it to make parts for machines or tools. When using a lathe, you should always wear safety gear like goggles. Follow the guide carefully to avoid mistakes. Remember, practice helps you get better!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Components Of A Metal Lathe And Their Specific Functions In The Machining Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe has several important parts. The bed is the base that holds everything steady. The headstock spins the metal piece, while the tailstock helps support it. The carriage moves tools to cut the metal into the right shape. Lastly, the tool post holds the cutting tool in place. Together, they help us create shapes from metal!”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up And Align A Metal Lathe For Precision Turning Of Metal Parts?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe, first, make sure it’s on a flat surface. Next, check that the tailstock and headstock are lined up straight. You can use a ruler or a straight edge for this. Then, secure the metal part in the lathe’s chuck, which holds it steady. Finally, adjust the speed and feed rate to get a smooth cut when you start turning. Always wear safety gear to protect yourself while working.”}},{“@type”: “Question”,”name”: “What Is The Difference Between Various Types Of Cutting Tools Used On A Metal Lathe, And How Do You Select The Right Tool For A Specific Application?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different cutting tools on a metal lathe have special shapes and sizes. Some tools are good for shaping, while others are best for cutting. To choose the right tool, think about what you want to do. If you need to make a smooth finish, pick a finishing tool. If you want to remove a lot of metal fast, use a roughing tool.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Operating A Metal Lathe To Prevent Accidents And Ensure Proper Handling Of Workpieces?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, you should always wear safety goggles to protect your eyes. Keep your hair tied back and wear tight-fitting clothes to avoid getting caught in the machine. Make sure to keep your hands away from moving parts. Always check that your workpiece is secure before starting the lathe. Lastly, know where the emergency switch is, so you can stop the machine quickly if needed.”}},{“@type”: “Question”,”name”: “How Can The Use Of Different Machining Techniques, Such As Facing, Turning, And Threading, Enhance The Capabilities Of A Metal Lathe In Metalworking Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using different machining techniques on a metal lathe helps us make many shapes and sizes of metal parts. Facing lets us make flat surfaces, which is important for fitting pieces together. Turning helps us shape the metal into round forms, like cylinders. Threading creates grooves, which are needed for screws and bolts. By using these techniques, we can create stronger and more useful metal items.”}}]}