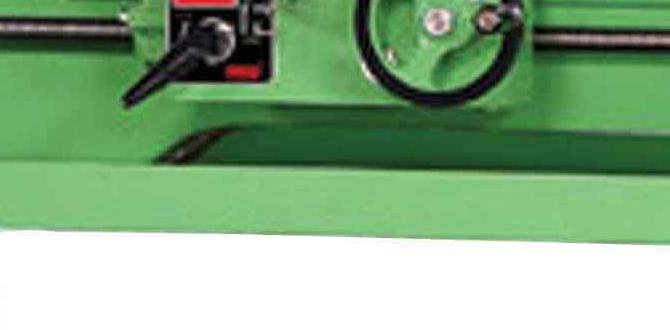

Have you ever watched a lathe machine at work? It’s like magic! A lathe transforms simple metal blocks into incredible shapes. One of the key parts in this process is the metal lathe saddle. But what exactly is it?

The lathe saddle holds the cutting tool and helps guide it along the metal piece. Without it, making precise cuts would be really hard. Think about trying to carve a statue without a steady hand! That’s how important the saddle is in lathe operations.

In this lathe application guide, we’ll dive deeper into the metal lathe saddle. We’ll explore its role, how it works, and why it’s essential for your projects. Ready to uncover the secrets of this amazing tool? Let’s get started!

Comprehensive Lathe Application Guide: Metal Lathe Saddle Insights

Lathe Application Guide: Metal Lathe Saddle

Metal lathe saddles play a key role in machining projects. They support the cutting tools and help guide the workpiece. Understanding their function can greatly improve your projects. Did you know that a well-aligned saddle can help prevent errors? A simple adjustment can enhance accuracy and finish quality. This guide provides tips on setting up and maintaining your metal lathe saddle for optimal performance. Explore how this crucial component can make your work smoother and more efficient!Understanding the Metal Lathe Saddle

Definition and purpose of the metal lathe saddle. Importance of the saddle in the overall lathe operation.A metal lathe saddle is a crucial part of the machine. It holds the cutting tool and moves it along the workpiece. This helps to shape and cut metal accurately. The saddle ensures that everything stays stable during operation. Without it, the lathe would not work properly.

- Holds the cutting tool securely

- Allows precise movements

- Enhances overall machine stability

- Improves the finished product quality

What is the purpose of the metal lathe saddle?

The purpose of the metal lathe saddle is to secure the tool and guide it accurately over the workpiece. This helps achieve clean cuts and smooth shapes in metal.

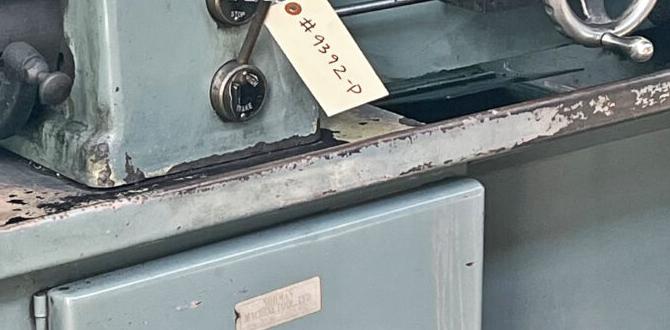

Components of a Metal Lathe Saddle

Detailed breakdown of saddle components (e.g., bed, ways, handwheels). How each component contributes to lathe functionality.A metal lathe saddle consists of several important parts. Each part helps the lathe work well. Here’s a quick look at the main components:

- Bed: This is the base. It keeps everything steady and strong.

- Ways: These are the smooth rails. They guide the saddle when it moves.

- Handwheels: These help users control the saddle’s movement. They make precise adjustments easier.

Understanding these parts helps you see how a lathe functions. Each component plays a key role in creating accurate and smooth workpieces.

What are the main components of a metal lathe saddle?

The main items are the bed, ways, and handwheels. Each offers support and precision for cutting tasks.

Mounting and Adjusting the Saddle

Stepbystep guide on how to mount a saddle on a metal lathe. Tips on adjusting saddle alignment for precision machining.Mounting the saddle on a metal lathe is important for smooth work. Here’s a simple guide to help you:

- Clean the lathe bed carefully.

- Align the saddle with the bed.

- Screw the saddle down gently but firmly.

- Check for any wobbling or tight spots.

To adjust for precision, make sure the saddle is level. Use a level tool to check this. Adjust the screws until it sits straight. Testing with a piece of metal can show how well it cuts. Small changes can make big differences!

How can I ensure proper saddle alignment?

To ensure proper alignment, frequently check with a level. Use a dial indicator to measure any misalignment. Adjust screws slowly for best results!

Common Issues and Troubleshooting

Identification of frequent saddlerelated problems. Effective troubleshooting tips and solutions.Problems can happen with a metal lathe saddle. Recognizing issues early makes fixing them easier. Common problems include:

- Misalignment: The saddle may not sit straight on the bed.

- Wear and tear: Parts can wear out over time.

- Inconsistent movement: The saddle may not move smoothly.

For quick fixes, ensure proper lubrication, check for debris, and adjust the screws for alignment. Regular maintenance can prevent many issues.

What are some common lathe saddle problems?

Some common problems include misalignment, wear and tear, and rough movement.

How can I troubleshoot my lathe saddle?

- Check alignment regularly.

- Lubricate moving parts often.

- Inspect for damage or wear.

Maintenance Best Practices for the Saddle

Recommended maintenance routines to prolong saddle lifespan. Common mistakes to avoid during saddle maintenance.Keeping your lathe saddle in top shape can save you time and trouble. Regularly check the saddle for dirt and debris. A quick wipe can go a long way! Apply oil to moving parts so they don’t get rusty. A ounce of prevention is worth a pound of cure! Avoid using too much force when tightening screws. This can lead to damage. Remember, your saddle isn’t a super-strong hero—gentle handling is key!

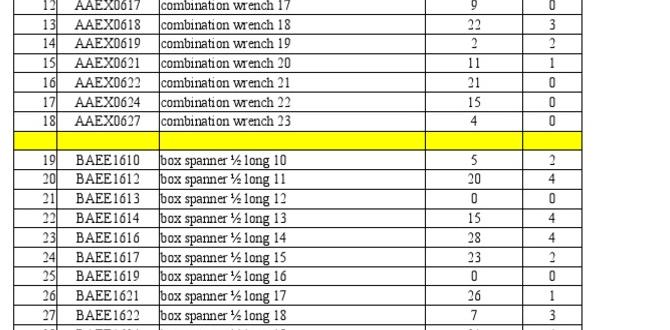

| Maintenance Routine | Common Mistakes |

|---|---|

| Clean regularly | Tightening screws too hard |

| Oil moving parts | Skipping inspections |

| Check for wear | Ignoring foreign debris |

By avoiding these mistakes, you help your lathe saddle last longer and work better. Happy lathe-ing!

Upgrades and Accessories for Enhancing Saddle Performance

Popular aftermarket upgrades for metal lathe saddles. How accessories can improve lathe efficiency and accuracy.Upgrading your metal lathe saddle can feel like giving your trusty steed a fancy makeover. Popular upgrades include better gibs, which help the saddle slide smoother—like butter! Accessories such as digital readouts and quick-change tooling can boost your lathe’s efficiency and accuracy. Imagine making precise cuts without the hassle. It’s like having a GPS for your metalworking adventures. Check out the table below for some awesome accessories!

| Accessory | Benefit |

|---|---|

| Upgraded Gibs | Smoother movement |

| Digital Readouts | Improved accuracy |

| Quick-Change Tool Holders | Faster setup time |

With these upgrades, your lathe can cut through metal like a hot knife through cheese. So go ahead, treat your lathe to a little upgrade love!

Safety Considerations When Using a Metal Lathe Saddle

Safety tips specific to saddle usage and maintenance. Importance of personal protective equipment (PPE) while operating a lathe.Using a metal lathe saddle safely is essential. Always check for loose parts before starting. Keep the work area clean. Proper maintenance helps avoid accidents. Make sure to wear personal protective equipment (PPE) like goggles and gloves. This shields you from flying debris and sharp edges. Here are some safety tips:

- Inspect the saddle regularly.

- Use clamps to secure materials.

- Never remove guards while the lathe is running.

Staying safe keeps you working well!

What is the importance of PPE when working with a lathe?

PPE protects your eyes, hands, and body from harm. Always wear appropriate gear to stay safe while using the lathe.Conclusion

In summary, the metal lathe saddle is crucial for accurate machining. It holds the workpiece securely, ensuring smooth cuts. You can improve your skills by practicing with different materials and setups. Explore more guides to deepen your understanding and enhance your projects. Start experimenting today, and see the amazing results you can achieve with your metal lathe!FAQs

Here Are Five Related Questions On The Topic Of Metal Lathe Saddle Application:Sure! A metal lathe saddle helps hold and move the workpiece while it spins. It keeps everything steady while we shape or cut the metal. This part is important for making sure our projects are nice and neat. Using the saddle properly helps us work safely and accurately. Always check that it is secure before starting!

Sure! Just ask your question, and I’ll be happy to help with a short answer.

What Is The Primary Function Of The Saddle In A Metal Lathe, And How Does It Contribute To The Machining Process?The saddle on a metal lathe helps hold the cutting tool in place. It moves along the bed of the lathe, which is the main part where everything is built. By moving the saddle, you control how the tool cuts the metal. This makes it easier to shape the metal into the right size and form. So, the saddle is very important for shaping metal correctly.

How Can One Properly Align And Adjust The Saddle For Optimal Performance During Turning Operations On A Metal Lathe?To align and adjust the saddle on a metal lathe, first, check that the lathe is level. You want it steady and straight. Next, loosen the screws on the saddle. Gently move it until it lines up correctly with the tool post. Finally, tighten the screws again to hold it in place. This will help your turning work go smoothly.

What Are Common Maintenance Practices To Ensure The Longevity And Accuracy Of The Saddle On A Metal Lathe?To keep the saddle on a metal lathe working well, we should clean it often. You can use a soft cloth to wipe off dust and dirt. It’s also important to check and add oil to the moving parts, so they do not get stuck. Finally, make sure the screws are tight to keep everything in place. This way, your lathe will last longer and work accurately!

How Does The Saddle Design Differ Between Manual And Cnc Metal Lathes, And What Implications Does This Have For Their Applications?The saddle on a manual lathe is simple and moves by hand. You control it by turning knobs. On a CNC lathe, the saddle moves automatically with a computer. This means CNC lathes can make more complex shapes faster. So, manual lathes are great for small jobs, while CNC lathes are better for big or complicated tasks.

What Are The Signs That Indicate A Saddle May Need Repair Or Replacement, And How Can One Troubleshoot These Issues Effectively?You can tell a saddle needs help if it has cracks, tears, or a loose seat. If the leather feels hard or the stirrups stick, that’s a sign too. To fix these issues, check if the screws are tight and clean the saddle regularly. If you see big damage, ask an adult to help you repair it or replace it. Always keep your saddle in good shape for riding safely!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Metal Lathe Saddle Application:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A metal lathe saddle helps hold and move the workpiece while it spins. It keeps everything steady while we shape or cut the metal. This part is important for making sure our projects are nice and neat. Using the saddle properly helps us work safely and accurately. Always check that it is secure before starting!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask your question, and I’ll be happy to help with a short answer.”}},{“@type”: “Question”,”name”: “What Is The Primary Function Of The Saddle In A Metal Lathe, And How Does It Contribute To The Machining Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The saddle on a metal lathe helps hold the cutting tool in place. It moves along the bed of the lathe, which is the main part where everything is built. By moving the saddle, you control how the tool cuts the metal. This makes it easier to shape the metal into the right size and form. So, the saddle is very important for shaping metal correctly.”}},{“@type”: “Question”,”name”: “How Can One Properly Align And Adjust The Saddle For Optimal Performance During Turning Operations On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align and adjust the saddle on a metal lathe, first, check that the lathe is level. You want it steady and straight. Next, loosen the screws on the saddle. Gently move it until it lines up correctly with the tool post. Finally, tighten the screws again to hold it in place. This will help your turning work go smoothly.”}},{“@type”: “Question”,”name”: “What Are Common Maintenance Practices To Ensure The Longevity And Accuracy Of The Saddle On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the saddle on a metal lathe working well, we should clean it often. You can use a soft cloth to wipe off dust and dirt. It’s also important to check and add oil to the moving parts, so they do not get stuck. Finally, make sure the screws are tight to keep everything in place. This way, your lathe will last longer and work accurately!”}},{“@type”: “Question”,”name”: “How Does The Saddle Design Differ Between Manual And Cnc Metal Lathes, And What Implications Does This Have For Their Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The saddle on a manual lathe is simple and moves by hand. You control it by turning knobs. On a CNC lathe, the saddle moves automatically with a computer. This means CNC lathes can make more complex shapes faster. So, manual lathes are great for small jobs, while CNC lathes are better for big or complicated tasks.”}},{“@type”: “Question”,”name”: “What Are The Signs That Indicate A Saddle May Need Repair Or Replacement, And How Can One Troubleshoot These Issues Effectively?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can tell a saddle needs help if it has cracks, tears, or a loose seat. If the leather feels hard or the stirrups stick, that’s a sign too. To fix these issues, check if the screws are tight and clean the saddle regularly. If you see big damage, ask an adult to help you repair it or replace it. Always keep your saddle in good shape for riding safely!”}}]}