Have you ever watched a metal lathe in action? It spins metal like magic! With the right setup, it can turn blocks of metal into beautiful parts. You might wonder how to achieve this wonder. A lathe application guide can help you understand the process.

Setting up a metal lathe may seem tricky, but it doesn’t have to be. Imagine making your own tools or toys. It’s like being a wizard with metal instead of spells! Our guide offers simple steps to get your lathe ready.

Did you know that a well-set-up lathe can make your work easier? It’s true! This article will walk you through everything you need to know about lathe setup. You’ll learn tips and tricks that can turn you into a metalworking pro in no time!

Lathe Application Guide: Metal Lathe Setup Explained

Lathe Application Guide: Metal Lathe Setup

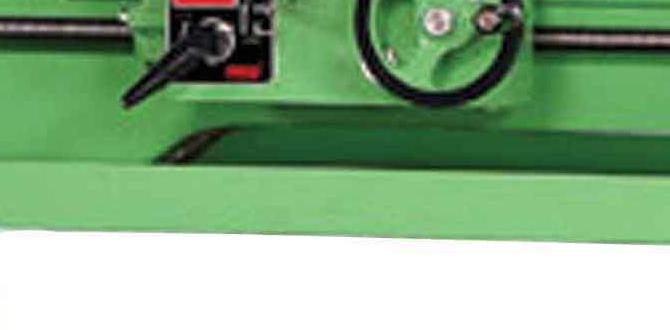

Setting up a metal lathe can be exciting and a bit tricky. You’ll learn how to choose the right tools and materials for your project. A metal lathe helps shape and cut metal into various forms. Did you know that with the right setup, even beginners can create amazing items? Understanding basic steps, like aligning the workpiece and choosing spindle speeds, makes a huge difference. With practice, you’ll go from novice to pro in no time!Understanding Metal Lathes

Explanation of metal lathe types. Key components of a metal lathe.There are several types of metal lathes, each serving different needs. Common types include:

- **Engine Lathes:** Great for general purpose work.

- **Turret Lathes:** Perfect for large batch production.

- **CNC Lathes:** Operated by computer for precise cuts.

Key components make lathes work effectively. Here are the main parts:

- **Bed:** The strong base that supports everything.

- **Headstock:** Holds the motor and rotates the workpiece.

- **Tailstock:** Supports the end of the workpiece.

- **Carriage:** Moves tools into place for cutting.

Understanding these types and components helps make metalworking easier. Metal lathes are powerful tools that can create many things from metal. Build your skills and see what you can create!

What are the main types of metal lathes?

The main types are engine lathes, turret lathes, and CNC lathes. They each have special features for different tasks.

Preparing Your Workspace

Guidelines for creating an effective workspace. Importance of safety measures in the workshop.Creating a friendly workspace is key to having fun while working. Start by keeping your area neat and organized. Make sure all tools are in their place, so you don’t have to play hide-and-seek every time you need a wrench! Safety matters here, too. Wear goggles and gloves, or you might end up with a funny story of your own. Let’s also check on the essentials. Here’s a simple table that might help:

| Guideline | Importance |

|---|---|

| Clear workspace | Keeps accidents at bay! |

| Safety gear | Prevents mishaps that give you extra holes. |

| Good lighting | Helps you see what you’re doing (no squinting allowed). |

Remember, a well-prepped space adds fun to your metal lathe setup! Now, let’s get working! 🛠️

Step-by-Step Lathe Setup

Detailed instructions for unboxing and initial inspection. How to level and secure the lathe.First, carefully unbox your lathe. Check for any damage right away. Make sure all parts are there. It’s important to keep parts organized.

Next, level your lathe. Use a bubble level at the top of the bed. Adjust the feet until it’s straight. Finally, secure the lathe to the bench. This helps it stay steady during use.

Following these steps will set you up for success!

How do you level a lathe?

Check the bed with a bubble level. Adjust the lathe feet until it looks straight. You can use shims if necessary.

Quick Tips:

- Always inspect for damage.

- Keep tools close and tidy.

- Ask someone for help if needed.

Calibrating the Metal Lathe

Importance of calibration for precision. Stepbystep calibration process.Calibration is key for making sure your metal lathe works just right. Without it, you might end up with wonky pieces that wouldn’t make it past the school Science Fair! Start by checking your tools with a reliable ruler and marking a reference line. Next, adjust the tailstock and ensure it lines up nicely with the spindle. Finally, confirm that your lathe speed is true by using a tachometer. This process makes your machine precisely accurate. Remember, a lathe that’s not calibrated well is like a pizza with no toppings—just not right!

| Step | Action |

|---|---|

| 1 | Check tool setup with a ruler |

| 2 | Adjust the tailstock alignment |

| 3 | Verify lathe speed with a tachometer |

By taking a little time to calibrate, you ensure each part comes out just like you planned. Precision is the name of the game!

Basic Turning Operations

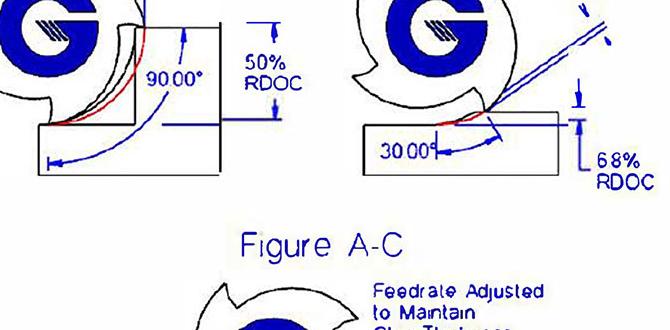

شرح أنماط التشغيل الأساسية مثلاً الخراطة. Tips for achieving optimal cutting speeds and feeds.Turning operations are the main part of using a lathe. This is where we cut shapes from a piece of metal. For smooth results, speed and feed are important. Here are some tips:

- Choose the right speed: Go slow for hard metals, fast for softer ones.

- Adjust the feed rate: A higher feed makes bigger cuts, while a lower feed smooths the surface.

- Keep tools sharp: A sharp tool cuts better and lasts longer.

Using these tips helps create good projects and enjoy working with lathes.

What are basic turning operations?

Basic turning operations include shaping, facing, and grooving. These methods help make the metal pieces you want.

Troubleshooting Common Issues

Identification of common setup problems. Solutions and adjustments for effective troubleshooting.Setup problems with a metal lathe can be tricky. Common issues include uneven cutting, vibrations, and poor finish. Identifying problems early is key for smooth operation. Here are some quick fixes:

- Check the tool height. If it’s too high or low, it can cause uneven cuts.

- Ensure the workpiece is tightened correctly to avoid vibrations.

- Inspect the blades for dullness. Sharper blades give a better finish.

Regular checks help keep your lathe running well. Small adjustments can make a big difference!

What are the common issues with lathe setup?

Common issues include uneven cuts, vibrations, and poor finish.

How can I solve lathe setup problems?

Check tool height, ensure tight workpieces, and inspect blade sharpness.

Maintenance Tips for Longevity

Routine maintenance practices for optimal performance. How to identify wear and tear on components.To keep your metal lathe running smoothly, regular maintenance is key. Lubricate the moving parts—it’s like giving your lathe a nice oil massage! Check for loose screws and tighten them. This avoids unexpected surprises, like a runaway tool.

If you notice strange noises or wobbly parts, it’s time to act! Look for wear and tear on components such as the spindle and bed. Early detection saves you from costly repairs later. Consistent care leads to a happy lathe and lasting performance.

| Maintenance Task | Frequency | Tip |

|---|---|---|

| Lubricate moving parts | Weekly | Use quality oil! |

| Tighten screws | Every session | Check for loosening! |

| Inspect for wear | Monthly | Listen for odd sounds! |

Resources for Further Learning

Recommended books and online courses. Relevant forums and communities for metal lathe enthusiasts.To improve your skills with metal lathes, there are many resources available. Books and online courses can provide valuable insights. Join forums and communities for metal lathe enthusiasts to connect with others. Here are some options:

- Books: Search for titles focused on metalworking and lathe techniques.

- Online Courses: Websites like Udemy and Coursera offer great classes.

- Forums: Check out Reddit and specialized metalworking forums to ask questions and share ideas.

- Communities: Join local clubs or online groups to learn from experienced makers.

What are the best online courses for lathe setup?

Udemy and Coursera are excellent platforms. They have user-friendly courses for different skill levels. Explore these options to find something that fits your learning style and pace.

Conclusion

In summary, understanding your metal lathe setup is essential for successful projects. You must choose the right tools and settings for your needs. Always prioritize safety by wearing protective gear. Practice using your lathe to improve your skills. For more detailed tips, explore guides or seek advice from experienced users. Happy turning!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Metal Lathe Setup And Application:Sure! When you set up a metal lathe, you need to make sure it is stable and level. You can do this by checking the surface it sits on. Next, you attach the workpiece securely so it doesn’t move. Then, you need to choose the right tools for the job. Lastly, always remember to wear safety gear to protect yourself!

Of course! Please go ahead and ask your question, and I will give you a simple answer.

What Are The Essential Components And Tools Required For Setting Up A Metal Lathe?To set up a metal lathe, you need a few important parts. First, you have the lathe itself, which spins the metal. Next, you need a chuck to hold the metal piece in place. You also need cutting tools to shape the metal. Lastly, make sure you have a sturdy stand to keep everything steady while you work.

How Do You Properly Align And Level A Metal Lathe To Ensure Accurate Machining?To align and level a metal lathe, first, check the floor. It should be even and strong. Use a bubble level to see if the lathe is straight. Adjust the feet of the lathe if needed, so it stands level. Finally, use a dial indicator to make sure the parts are straight and lined up. This will help you make accurate cuts.

What Safety Precautions Should Be Taken When Operating A Metal Lathe?When you use a metal lathe, always wear safety goggles to protect your eyes. Tie back long hair and avoid loose clothes to keep them away from the machine. Make sure your hands are clear of the moving parts. Keep the area clean and organized to prevent accidents. Finally, read the manual to understand how to use the lathe safely.

How Can You Choose The Right Cutting Tools And Inserts For Different Metal Lathe Operations?To choose the right cutting tools and inserts for metal lathe operations, start by looking at the metal type. Soft metals need different tools than hard metals. You should also think about the shape you want to make. Some tools work better for circles, while others are great for squares. Finally, ask someone experienced for advice if you’re unsure.

What Are The Common Troubleshooting Steps For Issues Encountered During Metal Lathe Setup And Operation?When you have problems with a metal lathe, first check the power supply. Make sure it’s plugged in and turned on. Next, look at the tools and make sure they are sharp and in the right position. If the machine is not moving well, check the settings and make sure they are correct. Lastly, if it still doesn’t work, ask for help from someone experienced.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Metal Lathe Setup And Application:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When you set up a metal lathe, you need to make sure it is stable and level. You can do this by checking the surface it sits on. Next, you attach the workpiece securely so it doesn’t move. Then, you need to choose the right tools for the job. Lastly, always remember to wear safety gear to protect yourself!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Please go ahead and ask your question, and I will give you a simple answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Components And Tools Required For Setting Up A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe, you need a few important parts. First, you have the lathe itself, which spins the metal. Next, you need a chuck to hold the metal piece in place. You also need cutting tools to shape the metal. Lastly, make sure you have a sturdy stand to keep everything steady while you work.”}},{“@type”: “Question”,”name”: “How Do You Properly Align And Level A Metal Lathe To Ensure Accurate Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align and level a metal lathe, first, check the floor. It should be even and strong. Use a bubble level to see if the lathe is straight. Adjust the feet of the lathe if needed, so it stands level. Finally, use a dial indicator to make sure the parts are straight and lined up. This will help you make accurate cuts.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Operating A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use a metal lathe, always wear safety goggles to protect your eyes. Tie back long hair and avoid loose clothes to keep them away from the machine. Make sure your hands are clear of the moving parts. Keep the area clean and organized to prevent accidents. Finally, read the manual to understand how to use the lathe safely.”}},{“@type”: “Question”,”name”: “How Can You Choose The Right Cutting Tools And Inserts For Different Metal Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To choose the right cutting tools and inserts for metal lathe operations, start by looking at the metal type. Soft metals need different tools than hard metals. You should also think about the shape you want to make. Some tools work better for circles, while others are great for squares. Finally, ask someone experienced for advice if you’re unsure.”}},{“@type”: “Question”,”name”: “What Are The Common Troubleshooting Steps For Issues Encountered During Metal Lathe Setup And Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you have problems with a metal lathe, first check the power supply. Make sure it’s plugged in and turned on. Next, look at the tools and make sure they are sharp and in the right position. If the machine is not moving well, check the settings and make sure they are correct. Lastly, if it still doesn’t work, ask for help from someone experienced.”}}]}