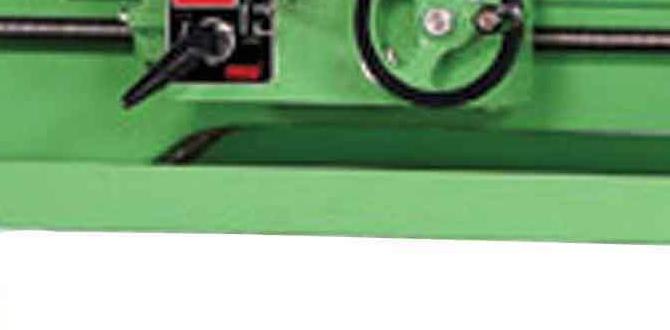

Imagine walking into a workshop filled with machines that whir and spin. Have you ever seen a lathe in action? It’s a fascinating tool that shapes metal into desired forms. But do you know the importance of a good lathe stand?

A proper metal lathe stand can change how you work. It gives your lathe the stability it needs to perform well. Without the right stand, your work could be tricky and even unsafe.

In this guide, we’ll explore the best lathe applications. You’ll learn how to choose the right metal lathe stand for your needs. Whether you are a beginner or an expert, this guide will help you make the most of your lathe.

So, are you ready to transform your metalwork experience? Let’s dive in and uncover the secrets to a solid lathe setup!

Lathe Application Guide: Choosing The Right Metal Lathe Stand

Lathe Application Guide for Metal Lathe Stand

Discover the essential features of a metal lathe stand and how they enhance your woodworking projects. A sturdy lathe stand ensures safety and stability when working with heavy materials. It is crucial for creating precise cuts and shapes. Did you know that an adjustable stand can help you achieve better ergonomics while working? Learning about different lathe stands can help you choose the perfect one suited for your needs. Unlock your creativity and enhance your craftsmanship today!Understanding Metal Lathes

Definition and functionality of metal lathes. Different types of metal lathes and their use cases.Metal lathes are fascinating machines that spin metal pieces while cutting them into different shapes. Think of it like a giant pencil sharpener for metal! These tools come in various types, each serving different jobs. For instance, a precision lathe is perfect for making tiny parts, while a turret lathe can churn out many identical pieces quickly. Each type has its own superpowers!

| Lathe Type | Use Case |

|---|---|

| Precision Lathe | Small, detailed projects |

| Turret Lathe | Mass production of parts |

| CNC Lathe | Automated precision work |

In short, metal lathes spin, cut, and help create everything from small screws to big machine parts! Understanding them opens up a world of possibilities in metalworking.

Importance of a Metal Lathe Stand

Benefits of using a dedicated stand for metal lathes. Impact on stability, safety, and precision.A sturdy stand for your metal lathe can make all the difference! It keeps your machine stable and reduces vibrations. This boosts accuracy, so your projects turn out just right. Think of a stand as a superhero cape for your lathe—making it stronger and safer. Plus, a solid base lowers the risk of accidents. With better precision, you’ll have fewer mistakes, which saves time and keeps you from tossing pieces into the recycle bin!

| Benefits | Impact |

|---|---|

| Stability | Reduces vibrations |

| Safety | Lowers accident risks |

| Precision | Improves accuracy of work |

Selecting the Right Metal Lathe Stand

Key factors to consider when choosing a stand. Comparison of materials (wood, steel, etc.).Choosing the right metal lathe stand is important for your projects. Here are some key factors to think about:

- Size: Make sure it fits your lathe properly.

- Stability: A stable stand keeps everything safe.

- Weight: Heavier stands help reduce vibration.

- Materials: Different materials have unique benefits.

Common materials include:

- Wood: Good for light use but may not last long.

- Steel: Strong and durable for heavy projects.

Think about your needs before making a choice. A great stand can make your work easier!

What should I consider when choosing a metal lathe stand?

Look for size, stability, and material. A good stand fits well and stays sturdy while working. Sturdy steel is often the best choice for heavy tasks.

DIY vs. Pre-Made Metal Lathe Stands

Pros and cons of building your own stand. Advantages and disadvantages of buying premade options.Building your own metal lathe stand can be a fun project. You can customize it to fit your needs, which sounds great, right? However, it takes time and tools that you might not already have—like a superhero without a utility belt. On the flip side, buying a premade stand is quick and easy. You can start creating right away, but it might not fit your exact needs. Think of it as a pizza; sometimes you want your favorite toppings, but other times, you just want a slice!

| DIY Metal Lathe Stand | Premade Metal Lathe Stand |

|---|---|

| Customizable | Quick to use |

| Time-consuming | Less flexibility |

| Potential cost savings | Ready-made solutions |

Setting Up Your Metal Lathe Stand

Stepbystep process for installing a metal lathe stand. Common mistakes to avoid during setup.To install your metal lathe stand, follow these simple steps:

- Find a flat, sturdy surface for the stand.

- Assemble the stand according to the manual.

- Make sure all parts are tight and secure.

- Level the stand using a ruler or level.

- Double-check measurements before placing the lathe.

Avoid these common mistakes:

- Skipping the assembly instructions.

- Ignoring wobbling or uneven surfaces.

- Overlooking secure connections.

Take your time, and remember, a stable stand makes for a better lathe experience!

What is the best way to level a metal lathe stand?

To level your metal lathe stand, use a level tool. Adjust the legs until the bubble is centered. Check both front-to-back and side-to-side to ensure it’s perfectly even.

Enhancing Your Metal Lathe Stand

Accessories and modifications for improved functionality. Tips for optimizing workspace around your metal lathe.Your metal lathe stand can be much more than a simple base. Adding accessories and making modifications greatly enhance its usefulness. Here are some ideas:

- Add a tool holder to keep your tools organized.

- Install a sturdy shelf for storing materials.

- Consider a height-adjustable stand for comfort.

- Use a VFD (Variable Frequency Drive) for speed control.

An organized workspace makes working easier. Keep your lathe space clean. Lay out tools close to your lathe. Lighting is key too! Good light helps see what you’re doing.

What can I add to my metal lathe stand?

You can add tool holders, shelves, and a VFD for better control.

How can I optimize my workspace?

- Keep tools near your lathe.

- Maintain a clean area.

- Make sure there is good lighting.

With these tips, your metal lathe stand can work better, making your projects even more fun!

Maintenance and Safety Tips

Best practices for maintaining your metal lathe stand. Safety measures to ensure a secure working environment.To keep your metal lathe stand in top shape, follow these easy tips. Regularly clean the stand to avoid rust and debris. Maintain proper lubrication on moving parts to prevent wear. Check for any loose bolts or screws that may cause problems. For safety, wear protective gear like goggles and gloves. Keep the workspace tidy to avoid accidents. Always read the instruction manual for proper usage.

What are some safety tips when using a metal lathe?

Ensure you wear safety goggles, keep hands clear of moving parts, and maintain a clean area to avoid hazards.

Best practices for maintenance:

- Keep the stand clean and dry.

- Lubricate the moving parts regularly.

- Check tightening on screws and bolts.

- Inspect for wear and tear often.

Common Issues and Troubleshooting

Identifying problems with metal lathe stands. Solutions for common standrelated issues.Metal lathe stands can sometimes cause headaches. You might notice wobbling or poor stability. That’s like trying to balance a unicycle on a tightrope! Check the legs for uneven surfaces; a tweak may do wonders. If your lathe is shaking, it could be too light for your projects. Adding a weight can help it stand strong like a superhero. Don’t forget to keep the area around your stand clean. Dirt can make it tip over! Here’s a quick table for common issues:

| Issue | Solution |

|---|---|

| Wobbling | Check for uneven legs |

| Shaking | Add extra weight |

| Slippage | Ensure it’s on a clean, dry surface |

Conclusion

In conclusion, a lathe application guide helps you understand how to use a metal lathe effectively. Build a sturdy lathe stand for stability and safety. Remember to follow safety precautions while working. For more tips and to enhance your skills, read more guides or watch videos online. Get hands-on and practice to become a pro with your lathe!FAQs

What Are The Key Factors To Consider When Selecting A Metal Lathe Stand For Optimal Stability And Performance?When picking a stand for your metal lathe, think about its weight. A heavier stand gives more stability, so the lathe won’t shake. Check that it fits your lathe size properly. You also want a stand made from strong materials. A good design helps keep everything level, which makes it easier to work.

How Can The Height Of A Metal Lathe Stand Impact User Comfort And Machining Precision?The height of a metal lathe stand matters a lot. If it’s too low, you might bend over, which is uncomfortable. If it’s too high, you could strain your arms. A stand at the right height helps you work better and keeps you comfortable, which helps you do precise work. This way, you make better cuts with less effort!

What Materials Are Recommended For Constructing A Sturdy And Durable Metal Lathe Stand?To build a strong metal lathe stand, you should use materials like steel or heavy-duty plywood. Steel is tough and won’t bend easily. Plywood is lighter but can also be strong if used thick enough. It’s important to use good screws and bolts to hold everything together. Make sure the stand is stable so your lathe works well!

How Do Different Designs Of Lathe Stands Affect The Accessibility And Arrangeability Of Tools And Accessories?Different designs of lathe stands can change how you reach your tools and accessories. Some stands are higher, making it hard to grab things easily. Others are lower and give you quick access. A stand with shelves helps you organize tools neatly, so you can find them faster. Good designs keep everything tidy and easy to use!

What Are Some Common Modifications Or Customizations That Can Be Made To A Metal Lathe Stand To Enhance Its Functionality?You can add shelves to hold tools and materials. A sturdy tabletop can support larger projects. Adding wheels makes it easy to move the lathe. We can also add a light for better visibility. These changes can help you work better and stay organized.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Factors To Consider When Selecting A Metal Lathe Stand For Optimal Stability And Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When picking a stand for your metal lathe, think about its weight. A heavier stand gives more stability, so the lathe won’t shake. Check that it fits your lathe size properly. You also want a stand made from strong materials. A good design helps keep everything level, which makes it easier to work.”}},{“@type”: “Question”,”name”: “How Can The Height Of A Metal Lathe Stand Impact User Comfort And Machining Precision? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The height of a metal lathe stand matters a lot. If it’s too low, you might bend over, which is uncomfortable. If it’s too high, you could strain your arms. A stand at the right height helps you work better and keeps you comfortable, which helps you do precise work. This way, you make better cuts with less effort!”}},{“@type”: “Question”,”name”: “What Materials Are Recommended For Constructing A Sturdy And Durable Metal Lathe Stand? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To build a strong metal lathe stand, you should use materials like steel or heavy-duty plywood. Steel is tough and won’t bend easily. Plywood is lighter but can also be strong if used thick enough. It’s important to use good screws and bolts to hold everything together. Make sure the stand is stable so your lathe works well!”}},{“@type”: “Question”,”name”: “How Do Different Designs Of Lathe Stands Affect The Accessibility And Arrangeability Of Tools And Accessories? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different designs of lathe stands can change how you reach your tools and accessories. Some stands are higher, making it hard to grab things easily. Others are lower and give you quick access. A stand with shelves helps you organize tools neatly, so you can find them faster. Good designs keep everything tidy and easy to use!”}},{“@type”: “Question”,”name”: “What Are Some Common Modifications Or Customizations That Can Be Made To A Metal Lathe Stand To Enhance Its Functionality? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can add shelves to hold tools and materials. A sturdy tabletop can support larger projects. Adding wheels makes it easy to move the lathe. We can also add a light for better visibility. These changes can help you work better and stay organized.”}}]}