Have you ever wondered how metal is shaped into various objects? One key tool that makes this possible is the lathe. Understanding your lathe is essential for anyone working with metal.

A lathe application guide can help you learn how to use this tool effectively. You might be surprised by how much torque plays a role in shaping metal. Torque is simply the twisting force that helps the lathe do its job.

Imagine crafting a beautiful piece of metal art. How do you think the right torque helps? It allows you to carve, cut, and shape with precision. With the right knowledge, you can create stunning projects.

In the following sections, we will explore everything you need to know about lathe applications. You will discover useful tips and tricks for mastering metal lathe torque. Get ready to dive into a world of creativity and skill!

Lathe Application Guide: Metal Lathe Torque Explained

Lathe Application Guide: Metal Lathe Torque

Understanding metal lathe torque is essential for achieving precision in your projects. Torque affects how well your lathe operates. Knowing the right settings can lead to smoother cuts and better finishes. Did you know that too much torque can harm your tools? By paying attention to your lathe’s torque settings, you can enhance efficiency and prolong tool life. Make sure to explore various applications in metalworking to see its benefits firsthand. Let’s dive into the world of lathe applications!Understanding Lathe Fundamentals

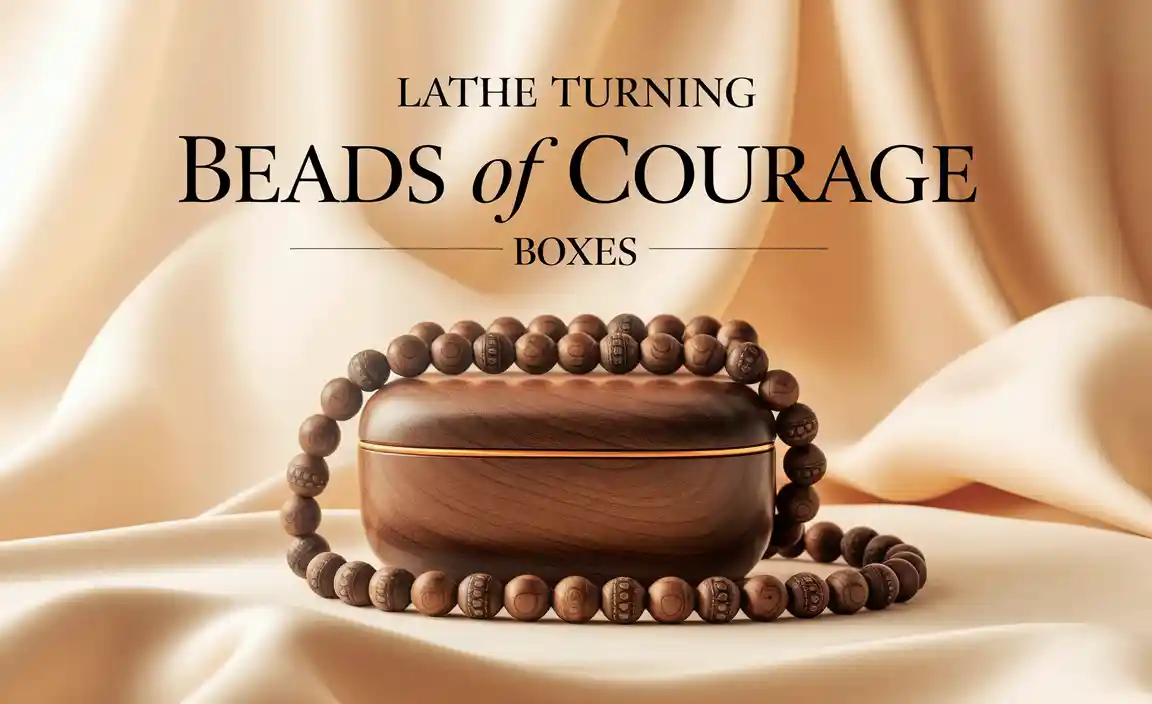

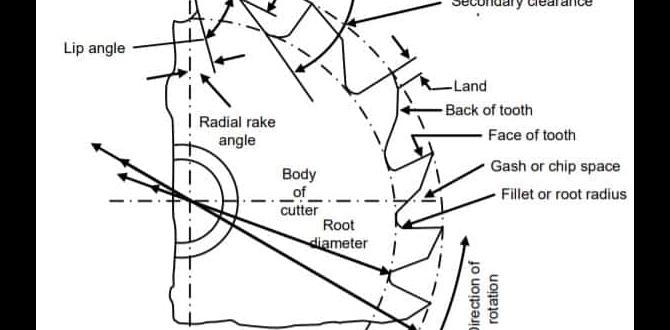

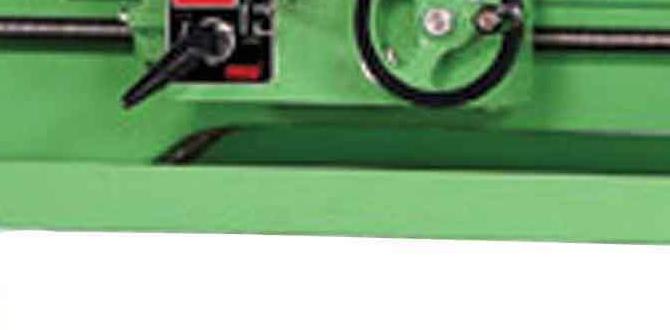

Definition and function of a metal lathe. Components and parts of a lathe machine.A metal lathe is a tool that shapes metal by spinning it. This machine removes material to create parts like rods and cylinders. It’s essential in industries and DIY projects. Key components include:

- Bed: The base that supports all parts.

- Headstock: Holds the motor and turns the workpiece.

- Tailstock: Supports the other end of the workpiece.

- Carriage: Moves the cutting tool along the metal.

Understanding these basics helps improve skills and projects. Each part works together to make shaping easier.

What does a metal lathe do?

A metal lathe shapes metal into various items by removing material. It is used to create parts for machines, tools, and more.

The Importance of Torque in Lathe Operations

Explanation of torque and its role in machining. How torque affects material removal rates and precision.Torque is like the muscle behind a lathe. It helps the machine spin and cut metal just right. If the torque is too low, the lathe might struggle, making ugly cuts. If it’s too high, it can harm the tool or the workpiece. Torque affects how quickly we can remove material and how precise those cuts are. Finding the perfect balance is key for smooth operations!

| Torque Level | Effect on Machining |

|---|---|

| Low Torque | Slow cuts, poor quality |

| Optimal Torque | Fast and precise cuts |

| High Torque | Risk of tool damage |

Remember, choosing the right torque is like picking the right snack. Too little or too much can ruin your day, but just the right amount makes everything better!

Calculating Required Torque for Lathe Operations

Formula and factors influencing torque calculations. Examples of torque requirements for different materials.To figure out how much torque a lathe needs, you use a simple formula: Torque = Force x Distance. Force comes from how hard the tool pushes against the material, and Distance is how far the force acts from the center. Factors like the type of metal and tool sharpness affect this calculation. For instance, steel requires more torque than aluminum because it’s tougher to cut. Here’s a quick comparison:

| Material | Required Torque (Nm) |

|---|---|

| Aluminum | 5 |

| Steel | 15 |

| Brass | 10 |

So, remember, the harder the material, the more torque you need! And that’s not just a fun fact; it’s crucial for smooth turning. Your lathe will be happier and work better with the right torque!

Optimizing Torque Settings

Techniques for adjusting torque settings on lathes. Common mistakes and how to avoid them.Getting torque settings right on a lathe is key for great work. Adjusting torque can be tricky, so follow these simple steps. First, use a torque wrench to check settings accurately—it’s like using a magic wand for your lathe! Avoid common mistakes, like cranking too hard, which can lead to breakage. Always tighten screws gently; we want to make pieces, not puzzles!

| Common Mistakes | How to Avoid |

|---|---|

| Over-tightening | Use the right tool and listen for clicks! |

| Ignoring specifications | Always check your lathe manual! |

| Poor maintenance | Keep it clean and lubed, or it’ll get cranky! |

Remember, a little care goes a long way. Torque settings don’t have to be scary. Think of it like cooking; just follow the recipe, and your lathe will serve up a masterpiece!

Safety Considerations in Lathe Operations

Importance of torque management for safety. Best practices for ensuring safe lathe use while maximizing performance.Using a lathe can be fun, but safety is a big deal. Proper torque management helps prevent accidents and keeps you safe. Too much torque? You might as well invite chaos! Follow these best practices: always wear safety glasses, keep your workspace clean, and use the right tools. Remember, a lathe isn’t just a machine; it’s a wild beast that needs gentle handling!

| Safety Tips | Description |

|---|---|

| Wear goggles | Protect your eyes from flying debris. |

| Keep it tidy | A clean work area cuts down on trips and slips. |

| Use proper tools | Using the right gear makes everything smoother. |

Stay smart and safe while lathe-ing! Remember, safety first, fun second. Who knew managing torque could be this exciting?

Maintenance Tips for Longevity and Efficiency

Regular checks and maintenance routines to ensure optimal torque. Importance of lubrication and component inspection.To keep your lathe running smoothly, regular checks are essential. Schedule maintenance tasks to check for wear and tear. Pay close attention to lubrication. It helps parts move freely and can prevent damage. Always inspect components for cracks or loose parts. A few minutes spent on upkeep can save you from costly repairs later.

- Check belts and gears for wear.

- Lubricate moving parts to reduce friction.

- Inspect electrical connections regularly.

How do I maintain my lathe for optimal torque?

For optimal torque, ensure proper lubrication and timely inspections. This helps extend machine life and improve performance.

Future Trends in Lathe Technology and Torque Management

Innovations in lathe technology affecting torque applications. The role of automation and smart technology in lathe operations.The future of lathe technology looks bright and buzzing with innovation! New designs allow for better torque management, making metal lathes more powerful and precise. Think of fancy gadgets like smart sensors that can adjust torque automatically, reducing the chance of mistakes. Automation is also joining the party, letting machines do the heavy lifting. Now, operators can sip their coffee while the lathe works!

| Innovation | Impact on Torque |

|---|---|

| Smart Sensors | Automatically adjust torque for accuracy |

| Automation | Reduces human error and increases efficiency |

With these trends, lathes may soon outperform our wildest dreams—maybe even brew a cup of coffee while they’re at it!

Conclusion

In summary, understanding torque is crucial when using a metal lathe. Proper torque ensures smooth cutting and accurate results. Remember to adjust settings based on the material you work with. For more tips, explore detailed guides or practice with scrap metal. With these insights, you can improve your skills and enjoy working with a lathe. Happy turning!FAQs

What Factors Should Be Considered When Calculating The Torque Required For Specific Metal Lathe Operations?When you calculate the torque for using a metal lathe, think about a few important things. First, consider the type of metal you are working with. Softer metals need less torque than harder ones. Next, look at how fast you want to turn the metal. Faster speeds can require more torque. Finally, think about the size of the tool you’re using on the lathe; bigger tools need more torque to work well.

How Does The Material Being Machined Affect The Torque Settings On A Metal Lathe?The material you are cutting on a metal lathe affects the torque settings you need. Softer metals need less torque, so you can turn the machine down. Harder metals need more torque, so you turn it up. If you use the wrong settings, it might damage your tools or the material. Always adjust the torque for the material you’re working with!

What Are The Common Signs That A Metal Lathe Is Operating With Insufficient Torque?If a metal lathe doesn’t have enough torque, you might notice some signs. The machine may make strange noises like grinding or whining. The tool might skid over the metal instead of cutting smoothly. You might also see rough or uneven edges on the metal piece. If the lathe stops suddenly, that’s another sign it’s struggling.

How Can The Torque Output Of A Metal Lathe Be Adjusted For Different Types Of Tooling Or Workpieces?To adjust the torque on a metal lathe, you can change the speed settings. Higher speeds give less torque, and lower speeds give more. You can also change the tools you use; some tools need more strength. If you have a heavier workpiece, use more torque to get better results. Always pay attention to how the lathe feels when you work!

What Is The Relationship Between Spindle Speed, Feed Rate, And Torque In Metal Lathe Applications?In metal lathes, spindle speed is how fast the machine spins the material. The feed rate is how quickly the cutting tool moves. When the spindle goes faster, you might need less force, or torque, to cut. If you go slower, you often need more torque because the tool pushes harder. So, the speed, feed rate, and torque work together to help us cut metal easily.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Factors Should Be Considered When Calculating The Torque Required For Specific Metal Lathe Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you calculate the torque for using a metal lathe, think about a few important things. First, consider the type of metal you are working with. Softer metals need less torque than harder ones. Next, look at how fast you want to turn the metal. Faster speeds can require more torque. Finally, think about the size of the tool you’re using on the lathe; bigger tools need more torque to work well.”}},{“@type”: “Question”,”name”: “How Does The Material Being Machined Affect The Torque Settings On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The material you are cutting on a metal lathe affects the torque settings you need. Softer metals need less torque, so you can turn the machine down. Harder metals need more torque, so you turn it up. If you use the wrong settings, it might damage your tools or the material. Always adjust the torque for the material you’re working with!”}},{“@type”: “Question”,”name”: “What Are The Common Signs That A Metal Lathe Is Operating With Insufficient Torque? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If a metal lathe doesn’t have enough torque, you might notice some signs. The machine may make strange noises like grinding or whining. The tool might skid over the metal instead of cutting smoothly. You might also see rough or uneven edges on the metal piece. If the lathe stops suddenly, that’s another sign it’s struggling.”}},{“@type”: “Question”,”name”: “How Can The Torque Output Of A Metal Lathe Be Adjusted For Different Types Of Tooling Or Workpieces? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the torque on a metal lathe, you can change the speed settings. Higher speeds give less torque, and lower speeds give more. You can also change the tools you use; some tools need more strength. If you have a heavier workpiece, use more torque to get better results. Always pay attention to how the lathe feels when you work!”}},{“@type”: “Question”,”name”: “What Is The Relationship Between Spindle Speed, Feed Rate, And Torque In Metal Lathe Applications? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In metal lathes, spindle speed is how fast the machine spins the material. The feed rate is how quickly the cutting tool moves. When the spindle goes faster, you might need less force, or torque, to cut. If you go slower, you often need more torque because the tool pushes harder. So, the speed, feed rate, and torque work together to help us cut metal easily.”}}]}