Have you ever wondered how to bring new life to an old lathe? If so, you’re in the right place! Rebuilding a lathe apron can seem tricky, but it offers a fun challenge. Imagine taking your worn-out machine and turning it into something brand new. Wouldn’t that be exciting?

Many hobbyists and professionals love to tinker with their tools. Did you know that a well-maintained lathe can last for decades? That’s right! With some simple lathe apron rebuild instructions, you can enhance your craftsmanship.

This article will guide you step-by-step. We’ll share easy tips and tricks that anyone can follow. Soon, you’ll see just how rewarding it is to repair your gear. Are you ready to dive into the world of lathe restoration?

Lathe Apron Rebuild Instructions: A Step-By-Step Guide

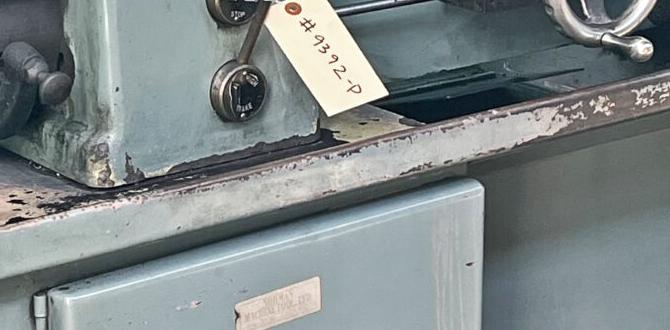

Lathe Apron Rebuild Instructions

Rebuilding a lathe apron can be a fun and rewarding project. First, gather the right tools and materials. You’ll need replacement parts, screws, and some basic tools. Did you know that a well-functioning apron keeps your lathe running smoothly? Start by disassembling the apron carefully. Inspect each part for wear and tear. Replace the worn components and reassemble everything meticulously. Finally, test it out! Isn’t it fascinating how a simple rebuild can enhance your lathe’s performance? Happy rebuilding!Understanding the Lathe Apron

Definition and function of the apron in a lathe. Common issues that necessitate a rebuild.The apron is a vital part of a lathe machine. It holds the carriage and controls its movement. This helps shape materials with precision. Unfortunately, aprons can face problems such as:

- Wear and tear from use

- Oil leaks that cause damage

- Sloppy movement affecting accuracy

When these issues arise, a rebuild is necessary. Fixing the apron restores its efficiency and extends the lathe’s life. A well-maintained apron ensures smooth operation.

What is a lathe apron used for?

The apron holds important controls. It helps the carriage move back and forth, allowing accurate cuts on the material. With a working apron, you can achieve quality results.

Common issues leading to apron rebuild

- Leaking oils

- Difficulty in moving the carriage

- Worn-out components

Tools and Materials Needed

Essential hand tools for the rebuild process. Recommended materials for replacement parts.To rebuild your lathe apron, you’ll need some key hand tools. Grab a wrench for tightening bolts and a screwdriver for those tricky screws. A file will help smooth out rough edges, and don’t forget safety gear for those “oops” moments! For replacement parts, think about using durable materials like steel or aluminum—they last longer than your last pair of socks! Below is a handy list of the must-have tools:

| Tool | Purpose |

|---|---|

| Wrench | Tightening bolts |

| Screwdriver | Removing screws |

| File | Smoothing edges |

| Safety Gear | Protecting yourself |

Preparing for the Rebuild

Safety precautions to take before beginning work. Steps for disassembling the lathe apron.Before diving into a lathe apron rebuild, safety comes first. Wear goggles to protect your eyes and gloves for your hands—because no one wants to add “injury” to their to-do list! Next, let’s tackle the disassembly. Start by gathering tools like wrenches and screwdrivers, then follow this simple table:

| Step | Description |

|---|---|

| 1 | Turn off the power to avoid any surprise start-ups. |

| 2 | Remove screws and bolts carefully. Keep them in a safe spot—your future self will thank you! |

| 3 | Detach the apron gently from the lathe body. |

Taking these steps ensures a smooth rebuild. Plus, you won’t be searching for lost parts like a detective on a case!

Inspecting Components for Wear and Damage

How to identify worn or damaged parts. Importance of detailed inspections before rebuilding.Before diving into a lathe apron rebuild, it’s smart to inspect each component closely. Look for signs of wear and damage, like cracks or unusual shapes. If something seems off, it probably is! Regular inspections help catch issues early, keeping your machine in tip-top shape. Remember, a small problem can become a big headache later. Here’s a quick table to help you spot trouble:

| Component | Signs of Wear | Action |

|---|---|---|

| Gears | Worn teeth | Replace |

| Screws | Rust or stripping | Replace |

| Bearings | Excessive play | Check and replace |

Paying attention to these details will save you time and money. Plus, you’ll avoid the drama of a broken lathe right when you need it most!

Step-by-Step Rebuild Instructions

Detailed instructions for replacing worn components. Tips for reassembling the apron correctly.Replacing worn parts of your lathe apron can feel like a treasure hunt. Start by carefully removing the old components. Keep track of every piece; it’s like a jigsaw puzzle! For reassembling, check your manual or this handy table:

| Component | Action |

|---|---|

| Gears | Replace and ensure they mesh perfectly. |

| Bearings | Check for wear; replace if needed. |

| Lubrication | Don’t skip this! A little oil goes a long way. |

Lastly, make sure everything lines up correctly. It’s more satisfying than finding a missing sock. And remember, if it doesn’t wiggle, it’s not right!

Common Mistakes to Avoid

Frequent pitfalls during the rebuilding process. How to troubleshoot common issues.Rebuilding a lathe apron can be difficult. Avoid these common mistakes to make it easier. First, don’t skip cleaning parts. Dirt can cause problems later. Second, check all screws and bolts. Loose parts can lead to issues. Third, follow instructions carefully. Missing steps can hurt your rebuild. If something goes wrong, here’s how to troubleshoot:

- Check if parts fit well.

- Look for unusual noises.

- Test the movement of all components.

With these tips, your rebuild should go smoothly!

What are common mistakes during rebuilding?

Common mistakes include skipping cleaning, not checking parts, and ignoring instructions.

How can I troubleshoot issues?

- Make sure everything fits together.

- Listen for any strange sounds.

- Check if all parts move freely.

Maintenance Tips for Longevity

Best practices for maintaining a rebuilt lathe apron. Recommended maintenance schedule to prevent future issues.To keep your rebuilt lathe apron in great shape, follow these simple tips. Regular maintenance ensures it runs smoothly. Here are the best practices for care:

- Clean the apron frequently to remove dust and debris.

- Check for loose screws and tighten them regularly.

- Lubricate moving parts to prevent wear and tear.

- Inspect for rust and treat it quickly.

Stick to a maintenance schedule. Monthly checks will help you catch problems early. This simple routine can save time and money in the long run.

What is the best way to maintain a lathe apron?

Regular cleaning and lubrication are key to keeping a lathe apron in good condition. Always check for any signs of wear during your maintenance routine.

Resources for Further Learning

Suggested books, videos, and forums for lathe enthusiasts. Where to find replacement parts and tools.For those who love lathes, many resources can help you learn more. Books like *The Lathe Book* by Ernie Conover offer great tips. YouTube has videos showing lathe projects step-by-step. Online forums like the Home Shop Machinist connect you with other fans. Need parts? Check sites like eBay or McMaster-Carr for tools and replacement parts. Remember, you’re not alone on this journey!

Where Can I Find Useful Lathe Resources?

Check out these helpful resources:

- Books: *The Lathe Book* by Ernie Conover

- Videos: YouTube tutorials on lathe projects

- Forums: Home Shop Machinist for discussions

- Parts: eBay and McMaster-Carr for tools

Conclusion

In conclusion, rebuilding a lathe apron can enhance your machine’s performance. You’ll need tools, patience, and clear instructions. Start by cleaning all parts and replacing worn components. Remember to follow step-by-step guides carefully. If you’re unsure, seek help from experts or online resources. We encourage you to dive deeper into lathe maintenance to boost your woodworking skills!FAQs

What Tools And Materials Are Required For A Lathe Apron Rebuild?To rebuild a lathe apron, you need some basic tools and materials. First, you will need a wrench to loosen and tighten screws. Next, grab a screwdriver for any small parts. You also need new gears and seals to replace old ones. Don’t forget some oil to keep everything running smoothly!

How Do You Disassemble The Lathe Apron For Inspection And Rebuilding?To take apart the lathe apron, you first stop the machine and unplug it. Then, use a wrench to remove the screws holding the apron in place. Carefully lift the apron off the lathe. Next, check each part for wear or damage. Now, you can fix or clean the parts before putting them back together.

What Are The Common Signs Of Wear Or Damage To Look For During The Apron Rebuild Process?When you check the apron, look for cracks or tears in the material. You should also see if there are any loose parts or missing pieces. Check for rust or other signs of corrosion on metal parts. If it feels weak or floppy, it needs fixing. These signs mean the apron is worn out and needs a rebuild.

How Can You Ensure Proper Alignment And Function Of The Lathe Apron After Reassembly?To make sure the lathe apron works well after putting it back together, you should check the parts carefully. First, use a level to see if everything is straight. Then, tighten all the screws, but don’t make them too tight. After that, move the apron back and forth to check if it slides smoothly. Finally, test the lathe to see if it works correctly.

What Maintenance Tips Should Be Followed After Rebuilding The Lathe Apron To Extend Its Lifespan?After rebuilding the lathe apron, you should keep it clean. Wipe off dust and oil daily. Check the parts for wear and tear. Always use the right oil to keep it running smoothly. Lastly, store it in a dry, safe place when not in use.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Tools And Materials Are Required For A Lathe Apron Rebuild? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To rebuild a lathe apron, you need some basic tools and materials. First, you will need a wrench to loosen and tighten screws. Next, grab a screwdriver for any small parts. You also need new gears and seals to replace old ones. Don’t forget some oil to keep everything running smoothly!”}},{“@type”: “Question”,”name”: “How Do You Disassemble The Lathe Apron For Inspection And Rebuilding? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To take apart the lathe apron, you first stop the machine and unplug it. Then, use a wrench to remove the screws holding the apron in place. Carefully lift the apron off the lathe. Next, check each part for wear or damage. Now, you can fix or clean the parts before putting them back together.”}},{“@type”: “Question”,”name”: “What Are The Common Signs Of Wear Or Damage To Look For During The Apron Rebuild Process? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you check the apron, look for cracks or tears in the material. You should also see if there are any loose parts or missing pieces. Check for rust or other signs of corrosion on metal parts. If it feels weak or floppy, it needs fixing. These signs mean the apron is worn out and needs a rebuild.”}},{“@type”: “Question”,”name”: “How Can You Ensure Proper Alignment And Function Of The Lathe Apron After Reassembly? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make sure the lathe apron works well after putting it back together, you should check the parts carefully. First, use a level to see if everything is straight. Then, tighten all the screws, but don’t make them too tight. After that, move the apron back and forth to check if it slides smoothly. Finally, test the lathe to see if it works correctly.”}},{“@type”: “Question”,”name”: “What Maintenance Tips Should Be Followed After Rebuilding The Lathe Apron To Extend Its Lifespan? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “After rebuilding the lathe apron, you should keep it clean. Wipe off dust and oil daily. Check the parts for wear and tear. Always use the right oil to keep it running smoothly. Lastly, store it in a dry, safe place when not in use.”}}]}