Have you ever wondered why some lathes work like new, while others struggle? It all comes down to lathe bed wear patterns. These patterns can tell a story about the lathe’s life and efficiency. Just like people, machines wear down over time. But what causes this wear? And how can we spot it before it becomes a big problem?

Imagine you’re playing on a slide at the park. If one side is worn down, it might not be safe to use. Similarly, a lathe with wear on its bed can cause issues with precision and quality. Did you know that the way a lathe is used can affect its wear patterns? This can surprise many people!

In the world of machining, understanding lathe bed wear patterns is key. It helps you maintain your tools and get better results. Join us as we explore how to identify these patterns and keep your lathe running smoothly.

Understanding Lathe Bed Wear Patterns: Causes And Solutions

Understanding Lathe Bed Wear Patterns

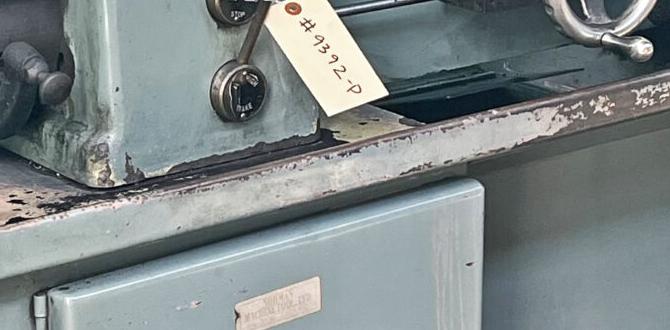

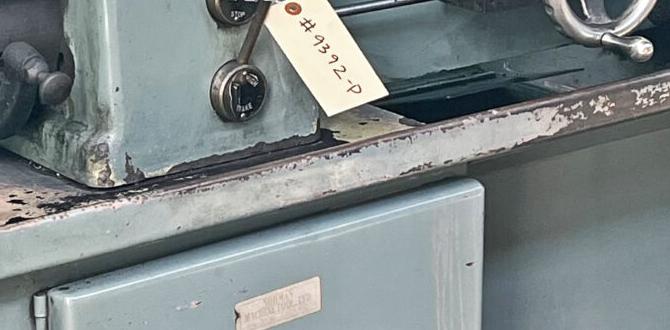

Lathe bed wear patterns reveal important clues about tool performance. Over time, lathe beds can show grooves, discoloration, or uneven surfaces from repeated use. These signs often mean your machine needs maintenance. Imagine trying to spin clay on a bumpy surface; it wouldn’t work well, right? Regular checks can prevent bigger problems. Did you know that minor adjustments can extend the life of your lathe? Paying attention to wear patterns keeps your projects smooth and precise.Causes of Lathe Bed Wear

Factors contributing to wear, including operational practices and environmental conditions. Materials and tools that exacerbate wear patterns.Lathe bed wear often sneaks up on you like a sneaky cat. Several factors lead to this wear and tear. First, operational practices play a big role. If a lathe is used too aggressively or without proper care, it wears out faster. Then there’s the environment—dust, humidity, and temperature changes can all be villains in the story. Also, using the wrong materials or tools can make things worse. Here’s a quick look:

| Factor | Impact |

|---|---|

| Operational Practices | Increased wear without proper techniques |

| Environmental Conditions | Dust and humidity can cause issues |

| Material Type | Poor materials lead to faster deterioration |

| Tool Choice | Incorrect tools can damage the bed |

Beware of these sneaky troublemakers; they can turn a perfectly fine lathe into a grumpy old machine!

Identifying Lathe Bed Wear Patterns

Visual inspection techniques for detecting wear. Tools and instruments for measuring wear severity.Checking the lathe bed for wear is like finding a hidden treasure, but instead of gold, you’re looking for clues. Use your eyes for a good ol’ visual inspection. Look for grooves, scratches, and shiny spots—those can be signs of wear. To get serious, grab tools like a dial gauge or a micrometer. These handy instruments can help measure wear severity. A simple table below illustrates some common tools:

| Tool | Purpose |

|---|---|

| Dial Gauge | Measures small distances |

| Micrometer | Gives precise measurements |

| Ruler | For quick checks |

These methods are easy and fun, like a scavenger hunt, but for lathe beds!

Impact of Lathe Bed Wear on Machining Accuracy

How wear impacts workpiece tolerances and surface finish. Case studies highlighting machining failures due to excessive wear.Wear on the lathe bed can cause big problems in machining. It can change the tolerances of workpieces, leading to mistakes. This affects how well pieces fit together. A rough surface finish can also appear due to wear. For example, one case showed a missing part caused by bed wear, resulting in costly repairs. Another case reported inaccurate dimensions, leading to wasted materials. Keeping the lathe bed in good shape is key to making quality parts.

How does lathe bed wear affect machining?

Lathe bed wear impacts both the precision and smoothness of machined parts.Key consequences include:

- Poor workpiece tolerances

- Rough surface finishes

- Increased chances of machining failures

Preventative Measures and Maintenance

Best practices for lathe bed care to minimize wear. Recommended maintenance schedules and procedures.Taking good care of your lathe can save you from headaches and costly repairs. Regular cleaning makes a big difference; a little dust can turn your machine into a beast! Use a soft cloth and avoid harsh chemicals. Check the bed for wear every month, especially after heavy use. Don’t forget to lubricate it; a well-oiled lathe runs like a dream. A monthly maintenance schedule could include:

| Activity | Frequency |

|---|---|

| Clean bed | Weekly |

| Check for wear | Monthly |

| Lubricate parts | Monthly |

| Full inspection | Quarterly |

A little care goes a long way. Remember, a lathe without maintenance is like a cat without naps—it just doesn’t work well!

Future Trends in Lathe Technology and Wear Reduction

Innovations in materials and coatings that reduce wear. The role of computeraided technology in monitoring bed conditions.Technology is always changing. Innovations are making lathe beds last longer. New materials and coatings help decrease wear. These materials are strong and smooth. They reduce friction during use. Additionally, computer-aided tools can watch the bed’s health. This technology helps spot issues early. It monitors tiny changes. This can prevent bigger problems and keep machines running well.

What materials and technologies help reduce lathe bed wear?

New materials like ceramic and advanced coatings can greatly reduce wear. Computer technology also plays a key role in monitoring these beds and ensuring they stay in good condition.

Conclusion

In summary, understanding lathe bed wear patterns helps you maintain your machine. Regular checks can prevent costly repairs. Look for grooves and scratches that signal wear. Keep your lathe bed clean and lubricated to extend its life. For more tips on maintenance, explore online resources or ask an expert. Taking good care now will pay off later!FAQs

What Are The Common Signs Of Wear Patterns On A Lathe Bed, And How Can They Be Visually Identified?You can see wear patterns on a lathe bed in a few ways. Look for scratches or grooves along the metal surface. You might also notice shiny spots where the metal is worn down. Check for uneven areas that don’t feel smooth. These signs show the lathe has been used a lot.

How Does The Material Composition Of A Lathe Bed Influence The Development Of Wear Patterns Over Time?The material of a lathe bed affects how it wears down. If the bed is made of hard metal, it lasts longer and wears less. Softer materials may scratch and wear out faster. Over time, the wear can change how the lathe works. This can make it harder to use or affect the things we make.

What Are The Potential Causes Of Uneven Wear On A Lathe Bed, And How Can They Be Mitigated?Uneven wear on a lathe bed can happen for a few reasons. If you don’t clean it often, dirt can cause problems. Using the lathe too much without checking its parts can also wear it out unevenly. To help prevent this, clean the lathe regularly and check its parts often. You should also make sure it sits on a steady, level surface.

In What Ways Does Lathe Bed Wear Affect Machining Accuracy And Part Quality?When the lathe bed wears out, it can make parts less accurate. This means the pieces might not fit together as they should. You might end up with shapes that are uneven or too big. Overall, worn beds can lead to parts that are not as strong or will break easily. Keeping the lathe bed in good shape helps make better parts.

What Maintenance Practices Can Be Implemented To Minimize Wear Patterns On A Lathe Bed And Extend Its Lifespan?To keep the lathe bed in good shape, you can do a few things. First, clean it often to remove dust and debris. Then, oil the bed regularly to keep it smooth. You should also check for loose parts and tighten them if needed. Finally, avoid heavy cuts that can cause extra wear on the bed.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Common Signs Of Wear Patterns On A Lathe Bed, And How Can They Be Visually Identified? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can see wear patterns on a lathe bed in a few ways. Look for scratches or grooves along the metal surface. You might also notice shiny spots where the metal is worn down. Check for uneven areas that don’t feel smooth. These signs show the lathe has been used a lot.”}},{“@type”: “Question”,”name”: “How Does The Material Composition Of A Lathe Bed Influence The Development Of Wear Patterns Over Time? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The material of a lathe bed affects how it wears down. If the bed is made of hard metal, it lasts longer and wears less. Softer materials may scratch and wear out faster. Over time, the wear can change how the lathe works. This can make it harder to use or affect the things we make.”}},{“@type”: “Question”,”name”: “What Are The Potential Causes Of Uneven Wear On A Lathe Bed, And How Can They Be Mitigated? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Uneven wear on a lathe bed can happen for a few reasons. If you don’t clean it often, dirt can cause problems. Using the lathe too much without checking its parts can also wear it out unevenly. To help prevent this, clean the lathe regularly and check its parts often. You should also make sure it sits on a steady, level surface.”}},{“@type”: “Question”,”name”: “In What Ways Does Lathe Bed Wear Affect Machining Accuracy And Part Quality? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When the lathe bed wears out, it can make parts less accurate. This means the pieces might not fit together as they should. You might end up with shapes that are uneven or too big. Overall, worn beds can lead to parts that are not as strong or will break easily. Keeping the lathe bed in good shape helps make better parts.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Can Be Implemented To Minimize Wear Patterns On A Lathe Bed And Extend Its Lifespan? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the lathe bed in good shape, you can do a few things. First, clean it often to remove dust and debris. Then, oil the bed regularly to keep it smooth. You should also check for loose parts and tighten them if needed. Finally, avoid heavy cuts that can cause extra wear on the bed.”}}]}