Have you ever wondered how machines create precise shapes and holes? A lathe is a fascinating tool that works wonders in many industries. Among its essential parts, the boring bar holder plays a crucial role. There are different types of lathe boring bar holders, each with its unique features.

What if I told you that choosing the right holder can make your projects smoother and faster? Imagine working on a piece of metal, and having the perfect tool brings your vision to life with ease. Understanding lathe boring bar holder types can help you pick the best one for your needs.

In this article, we’ll explore these types. You’ll discover how they differ and why these differences matter. Get ready to unlock new skills and knowledge about lathe boring bars!

Lathe Boring Bar Holder Types: A Comprehensive Guide

Lathe Boring Bar Holder Types

Choosing the right lathe boring bar holder can enhance your machining projects. You can find several types, each serving unique purposes. For example, some holders are designed for deep holes, while others excel at precision jobs. Ever considered how a simple change in the holder can improve your work? Understanding these options helps you make smart choices. A fun fact: different materials can also impact performance! Explore these types for better results and smoother machining experiences.Understanding Boring Bar Holders

Definition and purpose of boring bar holders. Importance in machining and CNC operations.Boring bar holders are important tools in machining. They hold a boring bar, which helps make precise holes in metal and other materials. These holders are key for CNC (computer numerical control) machines. They allow for accurate cutting and shaping. Without them, creating exact parts would be tough. They help improve work quality and speed. Using the right holder means better results and less waste.

What is the purpose of boring bar holders?

The purpose of boring bar holders is to securely hold boring bars. This ensures precision and accuracy in machining tasks.

Why are they important in machining?

- Enhance cutting accuracy

- Reduce material waste

- Speed up production time

Common Materials Used for Boring Bar Holders

Comparison of materials (steel, carbide, etc.). Impact of material choice on performance and durability.Different materials are used to make boring bar holders. The most common are steel and carbide. Each material has its own benefits and drawbacks. Steel is tough and can handle heavy tasks. It is also cheaper. However, it can wear out faster. Carbide, on the other hand, is stronger and lasts longer. It can cut harder materials without breaking. Choosing the right material is key to performance and durability.

- Steel: Tough and affordable.

- Carbide: Strong and long-lasting.

What are the benefits of these materials?

Steel is less expensive and works well for many jobs. Carbide is better for tough materials and has a longer lifespan.

Factors to Consider When Choosing a Boring Bar Holder

Compatibility with lathe machines. Size and range of boring tools.Choosing a boring bar holder can be tricky. First, check if it fits your lathe machine. Compatibility is key for safety and performance. Next, consider the size and range of your boring tools. Ensure the holder can accommodate the tools you need for your projects. The right choice can make your work easier and more efficient.

What should I consider for compatibility?

The boring bar holder must match your lathe machine’s specifications. This connection is crucial for smooth operation.

How do I know what size of boring tools to pick?

Check the dimensions of your tools. Look for a holder that supports their sizes well. A proper fit helps you achieve better results.

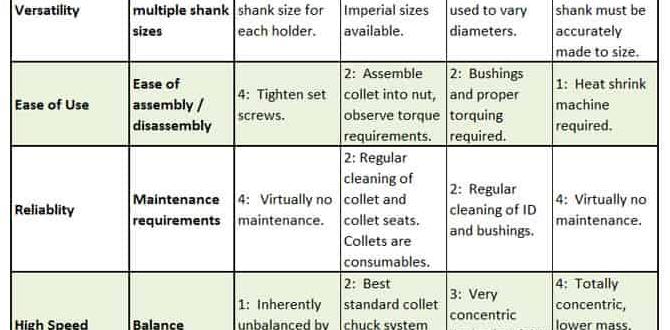

Adjustable vs. Fixed Boring Bar Holders

Differences in functionality and application. Advantages and disadvantages of each type.When it comes to boring bar holders, adjustable and fixed types have some notable differences. Adjustable holders can change positions, giving you more flexibility and control. This is great for various tasks, but they can feel a bit like a wobbly tooth if not set right! Fixed holders, on the other hand, are like a solid rock. They stay in place but limit your options. Both types have perks and quirks, so it really depends on what you need. You might prefer stability or flexibility, like choosing between a comfy couch and a fun trampoline!

| Boring Bar Holder Type | Advantages | Disadvantages |

|---|---|---|

| Adjustable | Flexible Can change positions easily |

Unstable Needs careful adjustments |

| Fixed | Stable Very reliable |

Limiting Less versatile |

Applications of Boring Bar Holders in Various Industries

Exploration of industries utilizing boring bar holders. Specific examples of machining tasks performed.Boring bar holders play a key role in many different industries, like manufacturing and automotive. They help make precise holes in large materials, ensuring everything fits just right. For instance, in the aerospace sector, these tools shape aircraft components. In the world of construction, boring bars help form tunnels for pipelines. It’s like having a tiny magician that makes big holes in hard things! Here’s a quick look at some industries and tasks:

| Industry | Task |

|---|---|

| Aerospace | Machining aircraft parts |

| Automotive | Creating engine blocks |

| Construction | Drilling tunnels |

| Oil and Gas | Making valve seats |

With boring bar holders, industries can work faster and more accurately, bringing the magic of engineering to life!

Maintenance Tips for Longevity of Boring Bar Holders

Best practices for care and maintenance. Troubleshooting common issues.Taking care of your boring bar holders keeps them running smoothly. First, always clean them after use. Dust and grime can mess things up. Store them in a safe, dry place. No one likes surprises like rust! Check for wear and tear regularly. It’s like checking your favorite toy for scratches. If you notice issues like vibrations or rough cuts, it might be time for a repair. Follow these steps, and your boring bar holders will last longer than your favorite pizza leftovers!

| Maintenance Tips | Common Issues | Troubleshooting |

|---|---|---|

| Clean after use | Weird vibrations | Check for tightness |

| Store properly | Rough cuts | Inspect cutting edges |

| Check for wear | Rust appearance | Clean and lubricate |

Emerging Trends in Boring Bar Holder Technology

Innovations in design and materials. Future outlook on boring bar holder advancements.New technologies are changing how boring bar holders are made. Today’s designs use stronger materials, making them lighter yet tougher. Imagine a superhero tool that can handle heavy jobs without breaking a sweat! Looking ahead, we expect more smart features, like sensors to monitor performance. These breakthroughs promise easier use and better precision. As one expert said, “The future looks bright, especially when our tools help us save time!”

| Innovation | Benefit |

|---|---|

| Lightweight Materials | Easier handling |

| Smart Technology | Improved efficiency |

Conclusion

In summary, lathe boring bar holders come in various types, each suited for different tasks. You should consider your project needs when choosing one. These tools help you achieve precise cuts and improve your work efficiency. For better results, explore different holder types and practice using them. Let’s dive deeper into the world of lathe tools together!FAQs

What Are The Different Types Of Lathe Boring Bar Holders And How Do They Differ In Terms Of Design And Functionality?Lathe boring bar holders help us cut inside materials. There are a few types, like the straight holder and the adjustable holder. The straight holder stays fixed, while the adjustable holder can change angles. Some are made for deep holes, and others fit in tight spaces. Each type helps us do different jobs better.

How Does The Choice Of Boring Bar Holder Affect The Precision And Surface Finish Of Machined Parts?The boring bar holder is important because it helps hold the tool steady. When it’s stable, you get better precision, meaning the part fits just right. A good holder also helps make the surface smooth. If the holder wobbles, the part can be rough and not look nice. So, choosing the right holder is key for making good parts.

What Materials Are Commonly Used To Manufacture Lathe Boring Bar Holders, And How Do They Influence Performance?Lathe boring bar holders are usually made from metal like steel or cast iron. These materials are strong and help hold the boring bars tightly. Sometimes, they use special coatings to reduce wear and friction. Strong materials make the holder last longer and work better when making holes.

How Do Adjustable And Fixed Boring Bar Holders Compare In Terms Of Ease Of Use And Versatility In Machining Applications?Adjustable boring bar holders let you change the size and angle easily. This makes them more versatile for different tasks. Fixed boring bar holders stay the same, so they are simpler to use. If you need to do many different jobs, adjustable holders are better. For one-time jobs, fixed holders are just fine.

What Factors Should Be Considered When Selecting A Boring Bar Holder For A Specific Lathe Machining Project?When choosing a boring bar holder for your lathe, think about the size of your boring bar. Make sure it fits well and is stable. Check the material of the holder; it should be strong enough for your job. Also, consider how easy it is to change the boring bar in and out. Lastly, think about how you will use it and if it will reach the places you need to work on.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Different Types Of Lathe Boring Bar Holders And How Do They Differ In Terms Of Design And Functionality? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe boring bar holders help us cut inside materials. There are a few types, like the straight holder and the adjustable holder. The straight holder stays fixed, while the adjustable holder can change angles. Some are made for deep holes, and others fit in tight spaces. Each type helps us do different jobs better.”}},{“@type”: “Question”,”name”: “How Does The Choice Of Boring Bar Holder Affect The Precision And Surface Finish Of Machined Parts? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The boring bar holder is important because it helps hold the tool steady. When it’s stable, you get better precision, meaning the part fits just right. A good holder also helps make the surface smooth. If the holder wobbles, the part can be rough and not look nice. So, choosing the right holder is key for making good parts.”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used To Manufacture Lathe Boring Bar Holders, And How Do They Influence Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe boring bar holders are usually made from metal like steel or cast iron. These materials are strong and help hold the boring bars tightly. Sometimes, they use special coatings to reduce wear and friction. Strong materials make the holder last longer and work better when making holes.”}},{“@type”: “Question”,”name”: “How Do Adjustable And Fixed Boring Bar Holders Compare In Terms Of Ease Of Use And Versatility In Machining Applications? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Adjustable boring bar holders let you change the size and angle easily. This makes them more versatile for different tasks. Fixed boring bar holders stay the same, so they are simpler to use. If you need to do many different jobs, adjustable holders are better. For one-time jobs, fixed holders are just fine.”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Selecting A Boring Bar Holder For A Specific Lathe Machining Project? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a boring bar holder for your lathe, think about the size of your boring bar. Make sure it fits well and is stable. Check the material of the holder; it should be strong enough for your job. Also, consider how easy it is to change the boring bar in and out. Lastly, think about how you will use it and if it will reach the places you need to work on.”}}]}