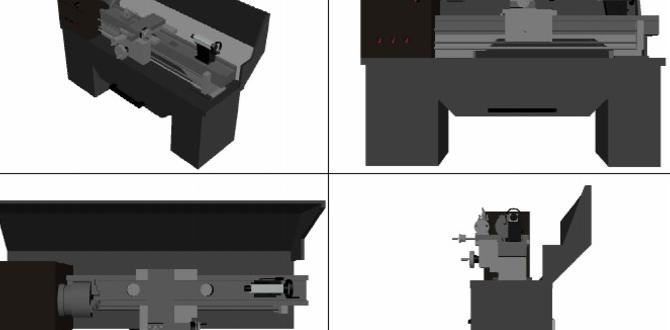

Imagine a machine that can shape metal with precision. It spins and cuts to create amazing parts. This machine is called a lathe. But how do we make a lathe even better? One answer is by using lathe CAD files. These files help design parts on a computer. They guide the machine on what to do next.

Have you ever wondered how automation can help make lathes smarter? Think about it. Instead of a person running the machine all the time, it can work on its own! This automation saves time and effort. It can do boring tasks, leaving people free to think of new ideas.

In today’s world, using lathe CAD files for metal lathe automation is becoming very popular. People in workshops and factories are discovering how it can improve their work. Join us as we explore this exciting topic and learn how these tools change the way we create things!

Lathe Cad Files For Metal Lathe Automation Solutions

Lathe CAD Files for Metal Lathe Automation

Lathe CAD files are essential for anyone diving into metal lathe automation. These files make designing parts simpler, saving time and effort. By using CAD technology, you can create precise drawings to guide your lathe. Imagine designing a unique piece without needing expert skills! Automation improves accuracy and speeds up production. Did you know that even small businesses benefit from using CAD files? With the right tools, anyone can achieve professional-quality results in their projects.Benefits of Using CAD Files for Metal Lathe Automation

Increased efficiency and precision in machining processes.. Reduction of errors and material waste in production..Using CAD files for metal lathe automation changes how we make parts. It boosts efficiency and improves precision. This means machines run faster and create better products. Mistakes drop, which cuts down on wasted materials. You save time and money!

- Increases machine speed

- Enhances accuracy in designs

- Reduces mistakes in processing

- Minimizes waste of raw materials

What are the benefits of using CAD files?

CAD files help create precise designs quickly. They also lower production errors and save material, which is key in manufacturing.

Types of CAD Files Suitable for Metal Lathes

Explanation of common CAD file formats (e.g., DXF, DWG, STL).. Comparison of different file types for specific lathe applications..Different CAD file formats serve various needs in metal lathes. Common types include:

- **DXF**: Great for 2D designs. It’s easy to use and widely supported.

- **DWG**: A popular choice for detailed drawings. Often used in professional settings.

- **STL**: Perfect for 3D printing. This format is best for creating complex shapes.

Each format is suited for different lathe applications. DXF is ideal for simple cuts. DWG works well for detailed mechanical parts. Lastly, STL is excellent for intricate designs. Choosing the right format helps achieve the best results!

What is the best CAD file for a metal lathe?

The best CAD file often depends on the project. For basic designs, DXF is usually recommended. For more complex parts, DWG or STL can be better choices.

How to Create and Source Lathe CAD Files

Stepbystep guide to creating custom CAD files for lathe projects.. Resources for downloading or purchasing premade lathe CAD files..Making your own lathe CAD files can be fun! First, choose a design idea. Next, use CAD software like AutoCAD or Fusion 360. Draw the parts carefully, and check your work. Don’t forget to save your files often!

If you want ready-made files, you can find many options online. Some popular places to get CAD files include:

- Thingiverse

- Cults3D

- GrabCAD

These websites offer lots of free and paid CAD files for your lathe projects.

Where to find premade lathe CAD files?

Many sites have premade lathe CAD files. Look on websites like Thingiverse or GrabCAD. You can download or buy them easily. Enjoy creating!

Case Studies: Successful Automation Using CAD Files

Examples of businesses that improved productivity through CAD file automation.. Analysis of specific projects and their outcomes..Many businesses have found success by automating their processes using CAD files for metal lathes. One company increased productivity by 40% after implementing CAD file automation. This allowed workers to focus on more important tasks instead of simple routines. Another project cut down production time by half! It’s funny how a digital file can save so much time, isn’t it? Let’s look at some examples:

| Business Name | Improvement | Outcome |

|---|---|---|

| Smith Manufacturing | 40% Productivity Boost | Happier Workers! |

| Jones Engineering | 50% Production Time Reduction | More Time for Creativity |

These examples show that CAD file automation can help boost efficiency and keep employees smiling!

Future Trends in Lathe Automation and CAD File Usage

Emerging technologies influencing lathe CAD file development.. Predictions for the future of CAD in metalworking automation..Exciting changes are coming in the world of lathe automation and CAD file use! New technologies are shaping how we create and manage these files. For instance, cloud-based tools are making sharing and editing easier than munching on a cupcake! Future predictions suggest that machines will work smarter, thanks to advancements like AI integration and real-time data analysis. This means metalworking could become quicker and even more accurate. Talk about a shiny future!

| Technology | Impact on CAD |

|---|---|

| AI | Enhances prediction and design accuracy |

| Cloud Computing | Fosters teamwork and file accessibility |

| Real-time Data | Improves machine performance |

Conclusion

In summary, using CAD files for metal lathe automation can improve your machining projects. You can create precise designs and save time. By exploring different CAD tools, you can enhance your skills and output. Dive into further resources online to learn more about this exciting area. Start experimenting today for better results and greater efficiency in your work!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Cad Files And Metal Lathe Automation:Sure! Lathe CAD files are digital drawings for lathes, a type of machine that shapes metal. We can use these files to design parts we want to make. Metal lathe automation means using machines to do the work instead of people. This helps make parts faster and more accurately. With automation, we spend less time on each project!

Sure! Just let me know your question, and I’ll be happy to help you with a simple answer.

What Are The Best Cad Software Options For Designing Parts To Be Produced On A Metal Lathe?Some great CAD (Computer-Aided Design) software for designing parts for a metal lathe are Autodesk Fusion 360, SolidWorks, and FreeCAD. Autodesk Fusion 360 is user-friendly and works well for beginners. SolidWorks is powerful for detailed designs and often used by professionals. FreeCAD is free and good for learning. You can choose any of these based on what you need!

How Can Automation Be Integrated Into A Metal Lathe Setup To Improve Production Efficiency?We can use machines that work automatically to help with metal lathes. For example, you can add robots to load and unload metal pieces. This lets the lathe keep working without breaks. We can also use software to control everything, making it faster and easier. With these changes, we can make more pieces in less time!

What File Formats Are Commonly Used For Cad Files In Metal Lathe Automation Processes?Common file formats we use for CAD (Computer-Aided Design) files in metal lathe automation include DXF and DWG. DXF stands for Drawing Exchange Format, which helps share designs easily. DWG is another format that helps keep the details of your design. We also use STL for 3D printing parts. These formats make it easier to create and work with metal pieces.

What Are The Key Considerations When Creating Cad Files For Cnc (Computer Numerical Control) Metal Lathes?When making CAD files for CNC metal lathes, you need to think about a few important things. First, your design should fit correctly on the metal piece you’ll use. Next, make sure to use the right shapes and sizes. You should also check that the lines are clear so the machine can read them easily. Lastly, save your file in a format that the CNC machine understands.

How Does The Use Of Cad Files Enhance The Precision And Repeatability Of Automated Metal Lathe Operations?Using Computer-Aided Design (CAD) files helps make metal lathe operations more accurate. These files show exactly how each piece should look. When we use CAD, machines know exactly what to do every time. This means we can create the same part again and again without mistakes. It makes our work faster and better!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Cad Files And Metal Lathe Automation:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Lathe CAD files are digital drawings for lathes, a type of machine that shapes metal. We can use these files to design parts we want to make. Metal lathe automation means using machines to do the work instead of people. This helps make parts faster and more accurately. With automation, we spend less time on each project!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know your question, and I’ll be happy to help you with a simple answer.”}},{“@type”: “Question”,”name”: “What Are The Best Cad Software Options For Designing Parts To Be Produced On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Some great CAD (Computer-Aided Design) software for designing parts for a metal lathe are Autodesk Fusion 360, SolidWorks, and FreeCAD. Autodesk Fusion 360 is user-friendly and works well for beginners. SolidWorks is powerful for detailed designs and often used by professionals. FreeCAD is free and good for learning. You can choose any of these based on what you need!”}},{“@type”: “Question”,”name”: “How Can Automation Be Integrated Into A Metal Lathe Setup To Improve Production Efficiency?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use machines that work automatically to help with metal lathes. For example, you can add robots to load and unload metal pieces. This lets the lathe keep working without breaks. We can also use software to control everything, making it faster and easier. With these changes, we can make more pieces in less time!”}},{“@type”: “Question”,”name”: “What File Formats Are Commonly Used For Cad Files In Metal Lathe Automation Processes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common file formats we use for CAD (Computer-Aided Design) files in metal lathe automation include DXF and DWG. DXF stands for Drawing Exchange Format, which helps share designs easily. DWG is another format that helps keep the details of your design. We also use STL for 3D printing parts. These formats make it easier to create and work with metal pieces.”}},{“@type”: “Question”,”name”: “What Are The Key Considerations When Creating Cad Files For Cnc (Computer Numerical Control) Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When making CAD files for CNC metal lathes, you need to think about a few important things. First, your design should fit correctly on the metal piece you’ll use. Next, make sure to use the right shapes and sizes. You should also check that the lines are clear so the machine can read them easily. Lastly, save your file in a format that the CNC machine understands.”}},{“@type”: “Question”,”name”: “How Does The Use Of Cad Files Enhance The Precision And Repeatability Of Automated Metal Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using Computer-Aided Design (CAD) files helps make metal lathe operations more accurate. These files show exactly how each piece should look. When we use CAD, machines know exactly what to do every time. This means we can create the same part again and again without mistakes. It makes our work faster and better!”}}]}