Have you ever wondered how metal lathe machines work? These amazing tools can shape metal with precision. But did you know that there is a simple way to improve your lathe experience? It’s all about using the right lathe CAD files.

CAD files can help you design the perfect parts for your metal lathe. They guide the machine, making it easier to cut shapes accurately. Plus, they save time and reduce mistakes. Think of them as instructions for building a LEGO set!

Now, let’s talk about another important feature: the metal lathe belt. A good belt ensures your lathe runs smoothly. If the belt is worn out, the machine can have problems. This can lead to frustration and wasted materials.

In this article, we will explore how to choose the right lathe CAD files and belts for your needs. Get ready to discover tips that can take your metalworking skills to the next level!

Lathe Cad Files: Essential For Metal Lathe Belt Design

Lathe CAD Files for Metal Lathe Belts

Do you dream of creating perfect metal parts? Lathe CAD files for metal lathe belts can turn that dream into reality. These files help you design custom belts that suit your lathe’s needs. You can enhance your metalworking skills with precise designs. Imagine fixing wear and tear before it happens. It’s like giving your lathe a new lease on life. Everyone loves a handy tool, right? Lathe CAD files make it easy for anyone to join the fun of metal crafting!Understanding Lathe CAD Files

Definition and purpose of CAD files. Types of CAD file formats commonly used in metalworking.CAD files are computer designs that help create products. They are like blueprints but way cooler! In metalworking, CAD files show how to make things like gears or tools. These files come in different shapes, just like ice cream flavors. Some popular formats used in metalworking are DWG, DXF, and STL. Each format has its special purpose, making the design process smoother. You wouldn’t want to use a chocolate scoop for vanilla, right? So choosing the right CAD file is key!

| CAD File Format | Purpose |

|---|---|

| DWG | Used for 2D and 3D designs. |

| DXF | Great for sharing drawings. |

| STL | Common for 3D printing. |

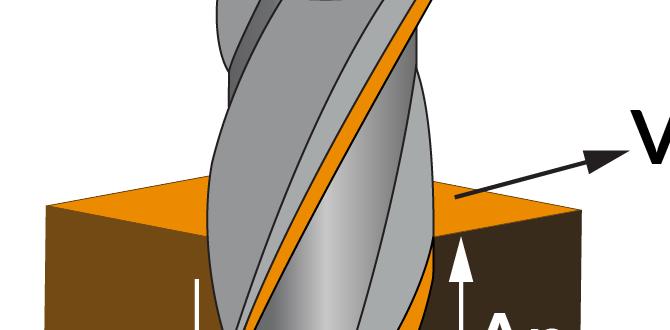

Creating CAD Files for Metal Lathe Belts

Stepbystep process for designing CAD files. Essential software tools for creating lathe CAD files.Designing CAD files for metal lathe belts is easier than baking a pie—well, almost! Start by picking the right software. Options like AutoCAD or Fusion 360 are great choices. They help you draw everything just right. Next, take a deep breath and follow these steps:

| Step | Description |

|---|---|

| 1 | Sketch the belt’s shape. |

| 2 | Add key measurements. |

| 3 | Finalize the design. |

| 4 | Export your file! |

Remember, practice makes perfect. Don’t be afraid to mess up. Even the best inventors had their flops—like the guy who tried to put wheels on a suitcase!

Best Practices for Lathe Belt Design

Key design considerations for durability and functionality. Tips for optimizing designs for manufacturing.Creating a belt for a lathe isn’t just about making it fit. You need to think about durability and functionality. A well-designed belt should be tough enough to handle wear and tear without sounding like a crying baby! Consider using strong materials and proper thickness. For easier production, simplify your design. Use fewer parts so assembly feels like a fun puzzle, not a nightmare!

| Design Element | Tip |

|---|---|

| Material | Choose strong, flexible options |

| Thickness | Balance durability and weight |

| Parts Count | Keep it simple for easy assembly |

Where to Find Quality Lathe CAD Files

Recommended online resources and marketplaces. Communities and forums for sharing and downloading CAD designs.Many good places offer lathe CAD files. Check out these online resources:

- Thingiverse: A big site for free designs.

- GrabCAD: A community for engineers to share files.

- TurboSquid: You can buy high-quality models.

Also, join forums and communities. Sharing ideas with others is valuable. Websites like Reddit have groups focused on CAD designs. You can ask questions, download files, and help others too!

Where can I get free lathe CAD files?

You can find free lathe CAD files on sites like Thingiverse and GrabCAD. They have many designs shared by users for free. Just search for what you need!

Common Mistakes to Avoid in Designing CAD Files

Top pitfalls when creating CAD files for lathe belts. How to troubleshoot common design issues.Designing CAD files can be tricky. Many people make mistakes that are easy to avoid. Here are common pitfalls in making CAD files for lathe belts:

- Ignoring measurements – Always check and double-check sizes!

- Not using layers – Different parts should go on separate layers for clarity.

- Missing details – Small details can make a big difference in the design.

- Overcomplicating designs – Keep it simple to avoid confusion.

If you face issues, look closely at your design. Check measurements and simplify when needed. Finding errors early can save time and effort.

What is a common mistake when creating CAD files?

One common mistake is forgetting to check measurements. Accurate measurements are crucial for a good design.

How can I troubleshoot CAD design issues?

To troubleshoot:

- Review all measurements.

- Break down complex parts into simple shapes.

- Use layering effectively.

By fixing these mistakes, your lathe belt designs will be much better!

Future Trends in Lathe CAD File Design

Innovations in CAD technology affecting metal lathe belts. Predictions for the future of lathe manufacturing and design.New technologies are changing how we design CAD files for metal lathes. Manufacturers are now using advanced software to create more precise and efficient designs. These innovations improve the performance of metal lathe belts. In the future, we can expect faster machines and better materials. Such advancements will help create even more durable and reliable lathes.

- More automation in design processes

- Improved software capabilities for custom designs

- Stronger and lighter materials for lathe belts

What are the advancements in CAD technology for metal lathes?

Advancements include faster software, better simulations, and automation, making designs more accurate.

What can we expect in the future of lathe manufacturing?

We can expect smarter machines, stronger materials, and a focus on sustainability.

Real-Life Applications of CAD Files in Metalworking

Case studies of successful implementations. Lessons learned from industry professionals.Many industries use CAD files for metalworking. These files help workers create precise parts easily. One success story comes from a car factory. They used CAD files to design engine parts. This cut production time by 30%. Industry experts stress teamwork. Working together leads to better results. Here are key lessons:

- Focus on accuracy to reduce waste.

- Regular team meetings improve design ideas.

- Feedback is essential for learning.

What are real-life examples of CAD in metalworking?

Many companies find CAD files useful. One example is a bicycle maker. They reduced costs by 20% using CAD.

Conclusion

In summary, lathe CAD files help you design and build metal lathes efficiently. The belt is crucial for smooth operation. Understanding these concepts will enhance your skills in metalworking. We encourage you to explore more resources on CAD design and lathe operations. Dive in, practice, and enjoy creating with lathes! Your metalworking journey starts now!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Cad Files For Metal Lathes And Their Belts:Sure! Lathe CAD files are special computer files. They help you design parts to use on metal lathes. These machines cut and shape metal. You can also find designs for the belts that help the lathe work. With these files, you can make your own parts or fix your machine!

Sure! Please tell me what question you’d like me to answer.

What File Formats Are Commonly Used For Cad Files Of Metal Lathe Designs And Accessories, Such As Belts?Common file formats for CAD (Computer-Aided Design) files include .DWG and .DXF. These files help us create and share designs. Another format is .STL, which is often used for 3D printing. You might also see .IGES or .STEP files; they help with sharing designs between different software. Each format helps us build and understand metal lathe designs and accessories better.

How Can I Ensure That The Cad Files For A Metal Lathe Belt Are Compatible With My Specific Lathe Model?To make sure the CAD files for a metal lathe belt fit your lathe, you first need to know your lathe model. Check the model number usually found on a sticker. Then, look for CAD files that match that model number. You can also ask the seller if the files are for your specific lathe. Finally, compare sizes in the CAD files with your lathe’s belt size to ensure a good fit.

What Factors Should I Consider When Designing A Metal Lathe Belt In Cad Software?When you design a metal lathe belt in CAD software, think about the size. Measure the length and width carefully. You also need to know how strong the belt needs to be. Make sure it fits well with the machine parts. Finally, consider the material; some materials last longer than others.

Are There Any Online Repositories Or Tools Where I Can Find Free Cad Files For Metal Lathe Parts, Including Belts?Yes, you can find free CAD files for metal lathe parts online. Websites like Thingiverse and GrabCAD are great places to start. You can search for specific parts, including belts. Just type what you need, and you’ll find many options! Enjoy creating your projects!

What Are The Best Practices For Modifying Existing Cad Files Of Metal Lathe Belts To Improve Performance Or Durability?To improve metal lathe belts, start by checking the design for weak points. You can make the belts thicker where they wear the most. Use strong materials to make them last longer. Test the new design to see if it works better. Finally, keep adjusting until you find the best fit!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Cad Files For Metal Lathes And Their Belts:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Lathe CAD files are special computer files. They help you design parts to use on metal lathes. These machines cut and shape metal. You can also find designs for the belts that help the lathe work. With these files, you can make your own parts or fix your machine!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please tell me what question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What File Formats Are Commonly Used For Cad Files Of Metal Lathe Designs And Accessories, Such As Belts?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common file formats for CAD (Computer-Aided Design) files include .DWG and .DXF. These files help us create and share designs. Another format is .STL, which is often used for 3D printing. You might also see .IGES or .STEP files; they help with sharing designs between different software. Each format helps us build and understand metal lathe designs and accessories better.”}},{“@type”: “Question”,”name”: “How Can I Ensure That The Cad Files For A Metal Lathe Belt Are Compatible With My Specific Lathe Model?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make sure the CAD files for a metal lathe belt fit your lathe, you first need to know your lathe model. Check the model number usually found on a sticker. Then, look for CAD files that match that model number. You can also ask the seller if the files are for your specific lathe. Finally, compare sizes in the CAD files with your lathe’s belt size to ensure a good fit.”}},{“@type”: “Question”,”name”: “What Factors Should I Consider When Designing A Metal Lathe Belt In Cad Software?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you design a metal lathe belt in CAD software, think about the size. Measure the length and width carefully. You also need to know how strong the belt needs to be. Make sure it fits well with the machine parts. Finally, consider the material; some materials last longer than others.”}},{“@type”: “Question”,”name”: “Are There Any Online Repositories Or Tools Where I Can Find Free Cad Files For Metal Lathe Parts, Including Belts?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, you can find free CAD files for metal lathe parts online. Websites like Thingiverse and GrabCAD are great places to start. You can search for specific parts, including belts. Just type what you need, and you’ll find many options! Enjoy creating your projects!”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Modifying Existing Cad Files Of Metal Lathe Belts To Improve Performance Or Durability?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To improve metal lathe belts, start by checking the design for weak points. You can make the belts thicker where they wear the most. Use strong materials to make them last longer. Test the new design to see if it works better. Finally, keep adjusting until you find the best fit!”}}]}