Have you ever wondered how metal pieces are made with perfect shapes? A lathe does just that! It spins metal and shapes it into amazing designs. But did you know that you can control these machines with something called a controller board?

In this article, we will explore lathe CAD files. These files help you design exactly what you want. Imagine being able to create your own parts and tools! It’s exciting, right? With the right metal lathe controller board, you can bring your ideas to life.

Did you know that many inventors started with simple lathes in their garages? They created wonderful things that changed the world. If you dream of creating your own projects, learning about lathe CAD files and controller boards can set you on the right path. Are you ready to discover how these tools can help you? Let’s dive in!

Lathe Cad Files: Metal Lathe Controller Board Explained

Understanding Lathe CAD Files and Controller Boards

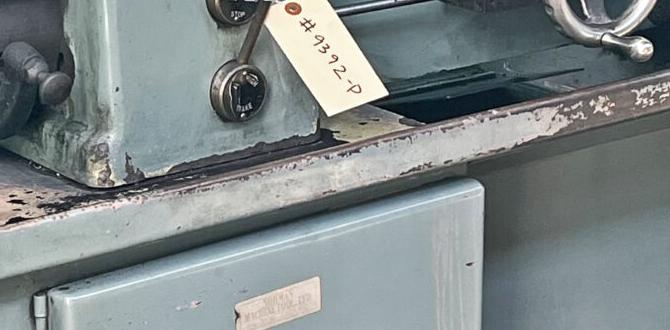

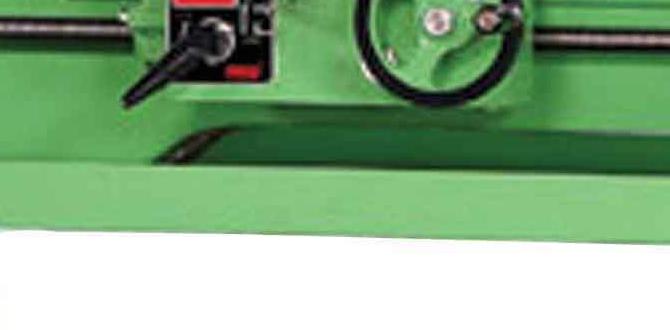

Lathe CAD files help designers create precise models for metal lathes. Did you know that these files can guide a lathe to cut metal with extreme accuracy? A lathe controller board acts as the brain of the machine. It interprets the CAD files and controls the movements of the lathe. This means users can make complex shapes easily. Whether you are a hobbyist or a pro, using these tools can open up endless possibilities in metalworking.Understanding Lathe CAD Files

Definition and significance of CAD files in lathe manufacturing.. Common formats and standards used for lathe CAD files..CAD files are like blueprints for a lathe. They help make sure everything fits together perfectly. When you have a good CAD file, you can save time and avoid mistakes. This is super important in lathe manufacturing because a tiny error can lead to a big mess—like trying to fit a square peg in a round hole!

Common CAD file formats include DXF, DWG, and STEP. Each format has its own special rules. Think of them like different languages in manufacturing. Knowing which one to use is key to smoother operations!

| Format | Description |

|---|---|

| DXF | Drawing Exchange Format, great for sharing designs. |

| DWG | A popular format for detailed drawings. |

| STEP | Used for 3D modeling, making it easy to visualize. |

Benefits of Using CAD Files for Metal Lathes

Improved precision and design flexibility.. Efficiency in the machining process and error reduction..Using CAD files for metal lathes improves precision and design flexibility. You can make detailed parts more easily. This leads to fewer errors. Efficient machining helps save time and materials. Workers can focus on their tasks instead of fixing mistakes. This approach can boost production.

- Better designs mean better products.

- Less time wasted fixing mistakes.

- Faster production leads to lower costs.

What are the advantages of CAD in metal lathes?

CAD files make work easier and faster, providing high-quality designs. They allow for changes without wasting resources, helping businesses grow.

How to Choose the Right Controller Board for Your Lathe

Key factors to consider when selecting a controller board.. Comparison of popular controller boards based on user needs and specifications..Choosing the right controller board for your lathe is like picking the best toppings for a pizza. You need the right mix! First, consider the compatibility with your lathe model. Some boards fit better than others. Then, look at the features you need, like speed control or programming options. Also, check user reviews; they can be more helpful than your cat’s opinion on naps! Here’s a quick comparison of popular boards:

| Controller Board | Compatibility | Key Features | User Rating |

|---|---|---|---|

| Board A | Model X | Speed Control, USB | 4.5/5 |

| Board B | Model Y | Wi-Fi, Easy Setup | 4/5 |

| Board C | Model Z | Advanced Programming | 5/5 |

In the end, pick the one that fits your needs like a glove. Happy lathe-ing!

Integrating CAD Files with Controller Boards

Stepbystep process on loading CAD files onto controller boards.. Troubleshooting common integration issues..Loading CAD files onto controller boards can feel like a tricky puzzle. But don’t worry! Follow these easy steps:

- First, prepare your CAD file. Make sure it’s in the right format.

- Next, connect your controller board to your computer. Plug it in and power it on.

- Then, use the software that matches your controller board. Upload your CAD file.

- Finally, check for any error messages. If something goes wrong, reset the board and try again.

Sometimes, you may face integration hiccups. Check connections and double-check your file format. A small mistake can feel like a big deal—like mixing up salt and sugar in a cake recipe!

| Common Issues | Quick Fixes |

|---|---|

| File not loading | Verify your file format. |

| Wiring problems | Inspect all connections. |

| Error messages | Restart and try again. |

With patience and these tips, you’ll be on your way to a successful integration! Happy crafting!

Examples of CAD Files for Metal Lathes

Sources where users can find highquality lathe CAD files.. Notable examples of CAD designs for specific lathe models..Finding top-notch CAD files for metal lathes is easier than you think. Websites like GrabCAD and Thingiverse offer a treasure trove of designs for all sorts of lathe models. Imagine whipping up a part while you sip cocoa! You can also check out forums where builders share their successful designs. Below are a couple of notable examples:

| Source | Example CAD File |

|---|---|

| GrabCAD | Mini Lathe Controller Board |

| Thingiverse | DIY CNC Lathe Adapter |

These examples can help jumpstart your projects. So, dive in and create something awesome—your lathe is waiting!

Best Practices for Designing Lathe CAD Files

Tips for creating effective and usable CAD designs for lathe work.. Common mistakes to avoid in lathe CAD file design..Creating effective CAD designs for lathe work is vital. Here are some tips to help you succeed:

- Start with a clear plan. Know what you want to make.

- Use precise measurements to avoid mistakes.

- Label parts clearly in your design.

- Regularly check your design for errors.

- Save different versions of your work.

Common mistakes to avoid include:

- Rushing the design process.

- Ignoring tool clearance and size.

- Forgetting to test your design.

With practice, you’ll create lathe CAD files that are effective and easy to use!

Why is it important to avoid mistakes in CAD files?

Avoiding mistakes ensures your designs are accurate and functional. Errors can lead to wasted materials and time. Properly designed files help achieve better results in your lathe work.

Future Trends in Lathe Technology and CAD Integration

Emerging technologies that may influence lathe CAD file usage.. Predictions for the future of metal lathe controllers and automation..New tools and tech are changing how we use lathe CAD files. For instance, 3D printing is making it easier to create custom parts. Imagine needing a special screw, and *poof*—it’s made! Automation is on the rise too. Future metal lathe controllers will probably work like magic, doing tasks faster than you can say “lathe!”

| Trends | Impact |

|---|---|

| 3D Printing | Custom parts creation |

| Automation | Speed and precision |

These changes mean less waiting and more doing. In the next few years, expect controllers that learn like a puppy—quick and eager to help. Who knows, you might even have a robot buddy by your side! Now that’s progress you can sink your teeth into.

Conclusion

In summary, lathe CAD files help design parts for metal lathes, while controller boards manage their operation. You can enhance your projects with these tools. If you’re interested in making your own designs, explore more online resources. By learning about CAD files and controller boards, we can improve our skills and create amazing projects together.FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Cad Files And Metal Lathe Controller Boards:Lathe CAD files are special drawings for making things on a lathe, which is a machine that shapes metal. A metal lathe controller board helps control how the lathe works. You can use these files to create parts for toys or machines. When we have a good plan, making things becomes easier and more fun! Would you like to know how to use them?

Sure! Please provide the question you’d like me to answer.

What Are The Key Features To Consider When Designing Cad Files For A Metal Lathe Controller Board?When designing CAD (Computer-Aided Design) files for a metal lathe controller board, you need to think about a few things. First, make sure the sizes of the parts fit together well. Second, use clear labels so everyone knows what each part does. You should also choose safe materials that won’t break easily. Finally, check that the layout helps the wires connect properly. This way, you can build a strong and effective controller board!

How Can I Convert Existing Lathe Control Circuit Designs Into Cad Files For Manufacturing?To convert lathe control circuit designs into CAD (Computer-Aided Design) files, start by drawing your design on paper. Then, use CAD software to recreate your drawing. This software lets you create digital versions of your designs. You can add details and measurements to make them ready for manufacturing. Finally, save your work in the right file format, like .dwg or .dxf, to share with manufacturers.

What Types Of Software Are Commonly Used For Creating Cad Files For Lathe Controller Boards?To create CAD files for lathe controller boards, we often use special software like AutoCAD and Fusion 360. These programs help you design parts and make plans for machines. You can see your designs in 3D, which makes it easier to understand how they fit together. Other options include FreeCAD, which is free to use, and SolidWorks, which is popular among professionals.

What Components Are Essential For A Metal Lathe Controller Board Designed For Cnc (Computer Numerical Control) Applications?A metal lathe controller board needs a few important parts. First, it has a microcontroller that helps control the lathe’s movements. You also need drivers to power the motors that move the tools. Connectors are necessary to attach different wires and parts. Finally, a power supply gives the board electricity to work. All these parts help the lathe follow your instructions and make precise cuts.

How Do You Ensure The Compatibility Of Cad Files With Specific Metal Lathe Models And Their Control Systems?To make sure CAD files work with metal lathes, we first check the file type. We use software to turn designs into a format the lathe understands. Next, we look at the metal lathe’s manual for special needs. Finally, we test the files on the machine to see if everything runs smoothly. This way, we fix any problems before we start working.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Cad Files And Metal Lathe Controller Boards:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe CAD files are special drawings for making things on a lathe, which is a machine that shapes metal. A metal lathe controller board helps control how the lathe works. You can use these files to create parts for toys or machines. When we have a good plan, making things becomes easier and more fun! Would you like to know how to use them?”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Features To Consider When Designing Cad Files For A Metal Lathe Controller Board?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When designing CAD (Computer-Aided Design) files for a metal lathe controller board, you need to think about a few things. First, make sure the sizes of the parts fit together well. Second, use clear labels so everyone knows what each part does. You should also choose safe materials that won’t break easily. Finally, check that the layout helps the wires connect properly. This way, you can build a strong and effective controller board!”}},{“@type”: “Question”,”name”: “How Can I Convert Existing Lathe Control Circuit Designs Into Cad Files For Manufacturing?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To convert lathe control circuit designs into CAD (Computer-Aided Design) files, start by drawing your design on paper. Then, use CAD software to recreate your drawing. This software lets you create digital versions of your designs. You can add details and measurements to make them ready for manufacturing. Finally, save your work in the right file format, like .dwg or .dxf, to share with manufacturers.”}},{“@type”: “Question”,”name”: “What Types Of Software Are Commonly Used For Creating Cad Files For Lathe Controller Boards?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To create CAD files for lathe controller boards, we often use special software like AutoCAD and Fusion 360. These programs help you design parts and make plans for machines. You can see your designs in 3D, which makes it easier to understand how they fit together. Other options include FreeCAD, which is free to use, and SolidWorks, which is popular among professionals.”}},{“@type”: “Question”,”name”: “What Components Are Essential For A Metal Lathe Controller Board Designed For Cnc (Computer Numerical Control) Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe controller board needs a few important parts. First, it has a microcontroller that helps control the lathe’s movements. You also need drivers to power the motors that move the tools. Connectors are necessary to attach different wires and parts. Finally, a power supply gives the board electricity to work. All these parts help the lathe follow your instructions and make precise cuts.”}},{“@type”: “Question”,”name”: “How Do You Ensure The Compatibility Of Cad Files With Specific Metal Lathe Models And Their Control Systems?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make sure CAD files work with metal lathes, we first check the file type. We use software to turn designs into a format the lathe understands. Next, we look at the metal lathe’s manual for special needs. Finally, we test the files on the machine to see if everything runs smoothly. This way, we fix any problems before we start working.”}}]}