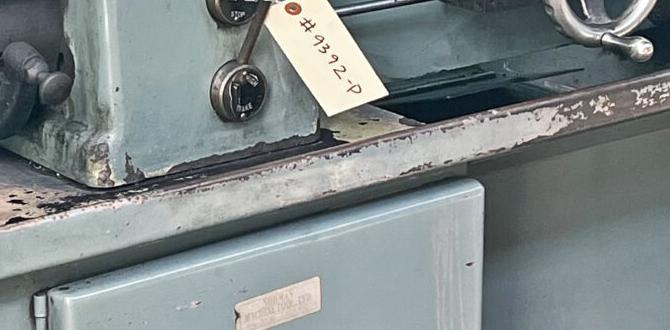

Have you ever wondered how metal parts are made? It’s not magic; it’s all about machines like the lathe. A lathe helps shape and cut metal, and its parts, like the cross slide, are super important.

Using lathe CAD files, you can design and customize these parts on a computer. Imagine being able to create your own unique cross slide! With just a few clicks, you can take your ideas and turn them into real objects.

Did you know that many hobbyists and professionals use these CAD files to enhance their lathe skills? They share tips and tricks on how to build the best metal lathe setups. The world of lathes is full of exciting possibilities!

If you’re curious about how to get started, you’re in the right place. Let’s dive into the fascinating world of lathe CAD files and discover how they can change your metalworking projects forever!

Lathe Cad Files: Metal Lathe Cross Slide Design Guide

Lathe CAD Files for Metal Lathe Cross Slide

Lathe CAD files help in designing precise cross slides for metal lathes. These files guide users to create accurate parts easily. Have you ever wondered how machinists achieve such detailed work? The right CAD design can make the process smoother. Using these files, you can learn to customize your lathe setup and enhance your workshop projects. Quite a few makers find that importing CAD files saves time and boosts creativity. Wouldn’t it be fun to craft your own parts?Understanding Lathe CAD Files

Definition and purpose of CAD files in machining. Importance of CAD files for designing lathe components.CAD files are like blueprints for machines. They help us design parts, like the cross slide of a metal lathe. These files show exactly where to cut and shape the metal. This makes machining much easier and faster! Without good CAD files, it would be like trying to bake a cake without a recipe—messy and confusing!

| Benefit of CAD Files | Explanation |

|---|---|

| Accuracy | They ensure your parts fit perfectly, just like finding the right puzzle piece! |

| Time-Saving | These files speed up the design process, like a fast-forward button for engineers! |

| Easy Changes | Need to fix a mistake? Just tweak the file and you’re good to go! |

In short, CAD files are essential tools that make designing lathe parts fun and efficient!

Creating a Cross Slide Design: Step-by-Step Guide

Instructions for selecting dimensions and materials. Tips for ensuring accuracy and functionality in your design.Choosing the right dimensions and materials is important for your cross slide design. Start by measuring the size of your lathe. Use strong materials like aluminum or steel for durability. Accuracy can be ensured by double-checking all measurements. Here are some tips:

- Select materials that fit your budget.

- Use precision tools to cut and assemble parts.

- Test the slide movement for smooth operation.

With these steps, your design will be accurate and functional!

How should I choose materials for my cross slide?

Choose strong and lightweight materials like aluminum or steel to ensure durability and functionality.

Best Practices for Using Lathe CAD Files

Tips for modifying existing CAD files for personal projects. Common mistakes to avoid when working with CAD in lathe design.Modifying CAD files can be fun and useful for your projects. Keep a few tips in mind:

- Check for mistakes before starting. Common errors can mess up your design.

- Don’t change too many things at once. It can be confusing.

- Save a backup of original files. You don’t want to lose your work.

- Use simple tools for edits. They can make changes easier.

To avoid problems, focus on clarity and precision. CAD can be tricky. Always double-check your work!

What are the best tips for modifying CAD files?

Keep it simple! Make small changes and save your work regularly. It helps keep everything on track.

Common mistakes to watch out for:

- Ignoring file backups

- Making too many changes at once

- Overlooking detail accuracy

Finding and Downloading Lathe CAD Files

Resources for accessing free and paid CAD files. How to assess the quality and compatibility of downloaded files.When searching for lathe CAD files, you can find both free and paid options online. Websites like GrabCAD and Thingiverse offer many free resources. For paid options, check out platforms like TurboSquid and CADblocks. Always read reviews first. This helps you spot quality files. You wouldn’t want a design that’s more wobbly than a three-legged chair!

| Resource Type | Example Websites |

|---|---|

| Free CAD Files | GrabCAD, Thingiverse |

| Paid CAD Files | TurboSquid, CADblocks |

Before downloading, check compatibility with your software too. Nobody likes a design that doesn’t fit! The web is filled with gems, so dig wisely and happy downloading!

Customizing CAD Files for Specific Metal Lathe Models

Adjusting designs to fit different lathe models and specifications. Importance of iteration and testing of customized designs.Customizing CAD files is essential for metal lathes. Each lathe model is unique, with different shapes and sizes. It’s crucial to adjust your designs to fit these specifications. Testing and iterating these designs ensures they work correctly. Iteration helps find errors and improve the final product, making it safer and more efficient.

- Measure your lathe carefully.

- Update designs to match these measurements.

- Run tests to check for fit and function.

- Revise as needed based on testing results.

Why is testing important in CAD designs?

Testing helps ensure designs fit and operate correctly, leading to better performance and safety.

Real-World Applications of Metal Lathe Cross Slides

Examples of projects where cross slide design plays a crucial role. Case studies showcasing successful lathe applications with CAD files.Cross slide designs in metal lathes make many projects possible. These designs help move tools in precise ways. Here are a few examples:

- Making custom brackets for machinery.

- Creating intricate metal parts for models.

- Producing tools and fixtures for workshops.

Case studies show how lathe CAD files improve these projects. A successful project may increase production speed by up to 30%. These designs lead to better accuracy, which means less waste. Using CAD files also helps in planning more complex shapes.

What makes cross slides important in lathe projects?

Cross slides allow for accurate tool movement. They help achieve detailed work on metal parts. This precision is key for quality products.

Future Trends in Lathe Design and CAD Technology

Insights into emerging technologies in machining and CAD. Potential impacts on the design and manufacturing of lathe components.Machining is about to get a makeover! New technologies are buzzing in the background, shaking things up in lathe design and CAD. Imagine using smart tools that communicate with each other – yes, it’s like a machine party! 3D printing and AI-driven designs are just around the corner. These advancements will change how we design lathe components, making them lighter and stronger. Soon, you might even get a customized lathe with a flashy personality! Check out the table below for some cool trends:

| Trend | Description |

|---|---|

| Smart Automation | Machines that talk to each other for better efficiency. |

| 3D Printing | Creating parts right from CAD files! |

| AI Integration | Designs that adapt based on usage patterns. |

Conclusion

In summary, lathe CAD files for metal lathe cross slides are essential for precise machining. They help you design and create parts accurately. Understanding these files boosts your projects’ success. If you’re interested, explore CAD software and practice making your designs. Keep learning about lathe techniques to improve your skills. Let’s start creating amazing projects together!FAQs

Sure! Here Are Five Questions Related To Lathe Cad Files And Metal Lathe Cross Slides:Sure! CAD stands for Computer-Aided Design. It helps you create designs on a computer. Cross slides help move tools on a metal lathe. They make it easy to cut shapes and sizes accurately. Using CAD files can help you build and plan projects better.

Sure! Just let me know what question you want me to answer, and I’ll help you with it.

What Are The Essential Design Considerations When Creating Cad Files For A Metal Lathe Cross Slide?When you create CAD files for a metal lathe cross slide, you need to think about a few important things. First, make sure the sizes are correct so everything fits well. Second, choose strong materials that can handle stress. Third, check that all parts move smoothly together. Finally, remember to plan for any tools or holders you might use. These steps help make sure your cross slide works perfectly!

How Can I Efficiently Convert Existing Metal Lathe Cross Slide Designs Into Cad Files?To change your metal lathe cross slide designs into CAD (Computer-Aided Design) files, start by measuring the pieces carefully. You can sketch them on paper first. Then, use CAD software to draw the shapes based on your sketches. If you have a scanner, you can scan your drawings and trace them in the CAD program. Finally, save your work as a CAD file to keep it safe.

What Cad Software Is Commonly Used For Designing Components Like Cross Slides For Metal Lathes?For designing parts like cross slides for metal lathes, we often use CAD software. Some popular options are SolidWorks, AutoCAD, and Fusion 360. These programs help you create 3D models and drawings. They make it easier to see how parts will fit together. Using CAD software is fun and helps you design better!

Are There Any Online Repositories Or Communities Where I Can Find Free Cad Files For Metal Lathe Cross Slides?Yes, you can find free CAD files for metal lathe cross slides online. Websites like GrabCAD and Thingiverse have many designs. You can search for “cross slide” there. These sites let you download files and even share your own designs. It’s a great way to learn and create!

What Are The Common Materials Used For Manufacturing Metal Lathe Cross Slides, And How Do They Affect The Cad Design Process?Metal lathe cross slides are often made from steel, cast iron, or aluminum. Steel is strong and good for heavy work. Cast iron absorbs vibrations, making things smoother. Aluminum is lightweight and easy to shape. These materials change how you design in CAD, or Computer-Aided Design, because you need to think about their strength and how they will hold up when used.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Lathe Cad Files And Metal Lathe Cross Slides:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! CAD stands for Computer-Aided Design. It helps you create designs on a computer. Cross slides help move tools on a metal lathe. They make it easy to cut shapes and sizes accurately. Using CAD files can help you build and plan projects better.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know what question you want me to answer, and I’ll help you with it.”}},{“@type”: “Question”,”name”: “What Are The Essential Design Considerations When Creating Cad Files For A Metal Lathe Cross Slide?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you create CAD files for a metal lathe cross slide, you need to think about a few important things. First, make sure the sizes are correct so everything fits well. Second, choose strong materials that can handle stress. Third, check that all parts move smoothly together. Finally, remember to plan for any tools or holders you might use. These steps help make sure your cross slide works perfectly!”}},{“@type”: “Question”,”name”: “How Can I Efficiently Convert Existing Metal Lathe Cross Slide Designs Into Cad Files?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To change your metal lathe cross slide designs into CAD (Computer-Aided Design) files, start by measuring the pieces carefully. You can sketch them on paper first. Then, use CAD software to draw the shapes based on your sketches. If you have a scanner, you can scan your drawings and trace them in the CAD program. Finally, save your work as a CAD file to keep it safe.”}},{“@type”: “Question”,”name”: “What Cad Software Is Commonly Used For Designing Components Like Cross Slides For Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For designing parts like cross slides for metal lathes, we often use CAD software. Some popular options are SolidWorks, AutoCAD, and Fusion 360. These programs help you create 3D models and drawings. They make it easier to see how parts will fit together. Using CAD software is fun and helps you design better!”}},{“@type”: “Question”,”name”: “Are There Any Online Repositories Or Communities Where I Can Find Free Cad Files For Metal Lathe Cross Slides?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, you can find free CAD files for metal lathe cross slides online. Websites like GrabCAD and Thingiverse have many designs. You can search for cross slide there. These sites let you download files and even share your own designs. It’s a great way to learn and create!”}},{“@type”: “Question”,”name”: “What Are The Common Materials Used For Manufacturing Metal Lathe Cross Slides, And How Do They Affect The Cad Design Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathe cross slides are often made from steel, cast iron, or aluminum. Steel is strong and good for heavy work. Cast iron absorbs vibrations, making things smoother. Aluminum is lightweight and easy to shape. These materials change how you design in CAD, or Computer-Aided Design, because you need to think about their strength and how they will hold up when used.”}}]}