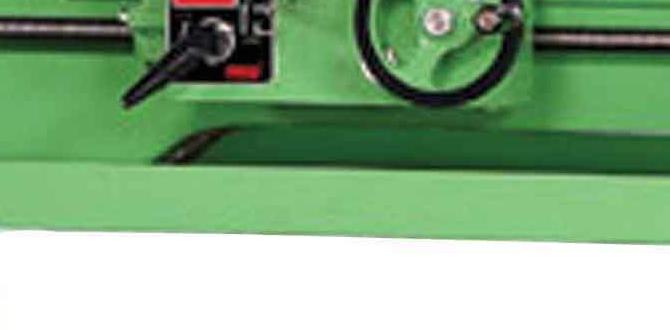

Have you ever wondered how machines shape metal? A lathe is one key tool in this process. It spins metal to create parts with precision. But how do you make your lathe even better? Enter CAD files! These digital files can help you design and build your own metal lathe gear train.

Imagine being able to create your own pieces, customized just for you. CAD files allow anyone, even beginners, to explore and learn. With the right designs, you can improve your lathe’s performance.

Did you know that gear trains can make a big difference? They help turn simple movements into complex ones. This means more power and speed for your lathe. Discovering how to use lathe CAD files can open up a world of exciting possibilities.

So, are you ready to dive into the world of metalworking? Let’s explore the amazing tools and designs that can turn your ideas into reality!

Lathe Cad Files For Metal Lathe Gear Train Design

Exploring Lathe CAD Files for Metal Lathe Gear Trains

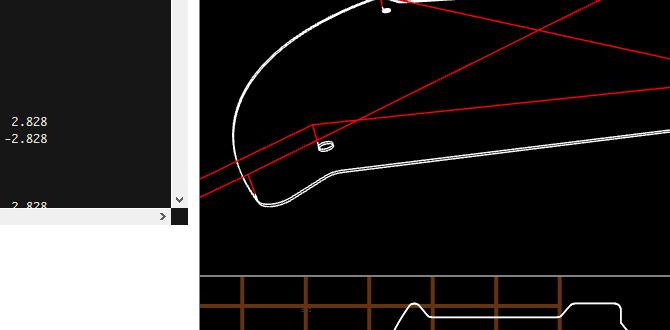

Lathe CAD files provide a detailed blueprint for designing metal lathe gear trains. Readers discover how these files help create precise gear arrangements. By using CAD software, users can visualize and test the gears before actual production. Did you know that even small design changes can greatly improve performance? Understanding these files enhances creativity in metalworking projects. This knowledge can lead to improved efficiency and better results in your craftsmanship.Basics of Metal Lathe Gear Train

Explanation of gear train functionality in metal lathes. Importance of gear ratios in lathe performance.Ever wonder how a metal lathe transforms raw materials into beautiful shapes? It all starts with the gear train. This system of gears controls the rotation of the lathe’s spindle, making it easier to shape metals. Think of it as a game of tag, where one gear passes the motion to another, creating smooth movements. The gear ratio is crucial here. It helps determine how fast or slow the lathe operates. A higher ratio means more torque, perfect for tougher materials, while a lower ratio makes for quicker spins, ideal for finer work.

| Gear Ratio | Effect |

|---|---|

| High Ratio | More torque for tough jobs |

| Low Ratio | Faster speeds for delicate work |

Types of Gear Trains in Metal Lathes

Description of common gear train configurations: simple vs. compound. Advantages and disadvantages of each type.Gear trains are like the superheroes of metal lathes! They come in two main types: simple and compound. A simple gear train is straightforward, using just one gear to drive another. It’s easy to manage and perfect for beginners. Compound gear trains, on the other hand, combine multiple gears, allowing for more flexibility and complex tasks. However, they can get tricky. Here’s a quick look at their differences:

| Type | Advantages | Disadvantages |

|---|---|---|

| Simple | Easy to use | Limited speed ranges |

| Compound | Versatile and more speeds | Complex setup |

Whether you’re a newbie or a pro, knowing your gear train type can help you make better cuts. Remember, even gear trains love a good laugh—just don’t let them get “tired” from too much work!

Creating Effective CAD Files for Gear Train Design

Key design considerations when drafting gear train components. Recommended software tools for CAD file creation.Designing gear train components is exciting. First, think about how each part fits together. Accuracy is key! Choose the right material for strength. Good spacing helps with movement. Use efficient tools for your CAD files. Here are some helpful software options:

- AutoCAD

- SolidWorks

- Fusion 360

These tools can help you create clear and detailed designs.

What are the main design considerations for gear trains?

Good design is important for how well gear trains work. Focus on size, strength, and spacing of gears. Each gear needs to fit just right to avoid problems.

Best Practices for Sharing and Using Lathe CAD Files

Tips for organizing and versioning CAD files. Collaborative tools and platforms for sharing designs.Keeping your lathe CAD files neat is like organizing your toy box—no one wants to dig for that one missing piece! Start by giving your files clear names and creating folders by project. Use version numbers like a comic book series; it’s easier to track changes that way. For sharing your designs, consider cloud services like Google Drive or Dropbox. They let you work with friends without risking a digital mess. Remember, teamwork makes the dream work!

| Tip | Description |

|---|---|

| Organize Files | Create clear folders and use descriptive names. |

| Version Control | Track changes using version numbers. |

| Collaborative Tools | Use cloud services like Google Drive for easy sharing. |

Common Challenges in Designing Gear Trains and Solutions

Analysis of frequent design pitfalls in gear train construction. Proven strategies and tools to overcome these challenges.Designing gear trains can be tricky. Some common problems include poor alignment, incorrect gear ratios, and inadequate support. Fixing these issues helps machines work better. Here are some tips:

- Check your measurements carefully before building.

- Use reliable software to find the right gear ratios.

- Test your designs using small models first.

- Get feedback from experienced builders.

Using these strategies can help you create better gear trains with fewer mistakes. Remember, practice makes perfect!

What are common mistakes in gear train design?

Some common mistakes include improper calculations, poor alignment, and ignoring material strength.

How can I improve my gear train designs?

Use specialized software, seek mentorship, and experiment with models to enhance your designs.

Case Studies: Successful Gear Train Designs Using CAD Files

Examples of innovative metal lathe projects utilizing CAD files. Lessons learned from successful implementations.Innovative metal lathe projects are all the rage! Take the case of a workshop that designed a super-efficient gear train using CAD files. They boosted productivity by 30%. Not too shabby, right? They learned that attention to detail is crucial. Mistakes in design can lead to funny (but costly) mistakes. Their motto? “Measure twice, CAD once!” Here are some other fun projects:

| Project | Success Rate | Key Lesson |

|---|---|---|

| Precision Gear Train | 95% | Be precise! |

| Adjustable Lathes | 90% | Flexibility is key. |

These case studies show how creative designs can lead to great success, and a few giggles along the way!

Future Trends in CAD Design for Metal Lathes

Exploration of emerging technologies in CAD software. Predictions on the evolution of gear train designs in the industry.Exciting things are happening in CAD design for metal lathes! New technologies, like 3D printing and VR, are changing the game. Designers can now create even more complex gear train systems faster and easier. Predicted trends show that designs will become more efficient, light, and powerful. Imagine a future where gear trains are so streamlined, they practically run on enthusiasm! Watch out, gears! You’ll be out of breath trying to keep up!

| Trend | Description |

|---|---|

| 3D Printing | Quickly creates complex parts. |

| Virtual Reality | Helps visualize designs before building. |

| Smarter Gear Designs | More efficient with less weight. |

Conclusion

In summary, lathe CAD files help you design metal lathe gear trains effectively. These files provide detailed blueprints to create precise gears. Understanding these designs lets you build better projects. If you’re interested, explore more resources online. You can start your own projects and improve your skills. Keep learning and enjoy creating with your lathe!FAQs

What Are The Key Components Of A Gear Train Used In A Metal Lathe, And How Do They Influence Machining Performance?A gear train in a metal lathe has a few important parts. These include gears, shafts, and belt drives. The gears help control the speed and direction of the machine. When they work well, they make the cutting smooth and accurate. This means you get better pieces when you’re done!

How Can Cad Files For A Metal Lathe Gear Train Be Modified To Accommodate Different Gear Ratios?You can change the size of the gears in the CAD file. If you make one gear bigger, the gear ratio changes. A bigger gear makes the machine move faster. You just need to save the new design after you change the gear sizes. Then, you can use it on the metal lathe!

What Are The Advantages Of Using Cnc-Generated Cad Files For Designing A Metal Lathe Gear Train Compared To Traditional Drafting Methods?Using CNC-generated CAD files is really helpful for making designs. First, you can see your design on the computer, which makes it easier to spot mistakes. Second, you can change things quickly if you want a new idea. Third, it helps make parts that fit together perfectly. Lastly, it saves time, so you can finish your project faster!

How Do The Materials Used In The Gear Train Components Affect The Durability And Efficiency Of A Metal Lathe?The materials in the gear train of a metal lathe are very important. Strong materials like steel make the gears last longer. When gears are made from good materials, they work better and use less energy. This helps the lathe cut metal smoothly without breaking. So, better materials mean the lathe is more durable and efficient.

What Software Tools Are Recommended For Creating And Editing Cad Files For Metal Lathe Gear Trains?To create and edit CAD files for metal lathe gear trains, you can use a few good software tools. TinkerCAD is great for beginners. Fusion 360 is more advanced and has lots of features. We also have FreeCAD, which is free and works well. All these tools help you design and change your gear train easily.