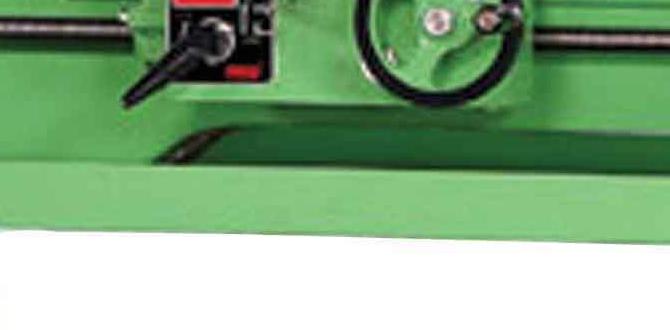

Lathe Cad Files: Essential For Metal Lathe Maintenance

Lathe CAD Files and Metal Lathe Maintenance

Lathe CAD files are useful for anyone working with metal lathes. They help create accurate designs and improve machining efficiency. Proper maintenance of a lathe keeps it running smoothly and extends its life. Regular cleaning and lubrication ensure better performance. Did you know a well-maintained lathe can perform more reliably and produce better quality work? Understanding how to care for your equipment is key to success in metalworking.Understanding Lathe CAD Files

Definition and purpose of CAD (ComputerAided Design) files in lathe manufacturing.. Different types of CAD files used in metal lathes (e.g., 2D, 3D models)..CAD files stand for Computer-Aided Design files. They help in creating designs for machines like lathes. These files are very important for making parts accurately and quickly.

There are different types of CAD files used in metal lathes:

- 2D models: These show flat designs and are easy to create.

- 3D models: These provide a detailed view of the part, showing depth and shape.

Using CAD files in metal lathes ensures better precision and efficiency in manufacturing.

What are the benefits of using CAD files in lathe manufacturing?

The benefits include faster production, higher accuracy, and better communication among team members.

Importance of CAD Files in Metal Lathe Operations

Enhancing precision and reducing errors in metal lathe processes.. Streamlining the designtomanufacturing workflow with CAD files..Using CAD files in metal lathe operations is like having a treasure map! It helps in enhancing precision and cutting down errors. Imagine you’re a pirate and you accidentally dig in the wrong spot. Yikes! CAD files streamline your design-to-manufacturing workflow, making the whole process smoother than butter. With accurate designs, you can create parts that fit perfectly, saving time and resources. Who doesn’t want to avoid a trip to the “oopsie” bin, right?

| Benefits of CAD Files | Impact on Operations |

|---|---|

| Higher accuracy | Fewer mistakes |

| Faster designs | Quicker production |

| Easy adjustments | Less waste |

Best Practices for Creating and Managing Lathe CAD Files

Tips for effective design creation in CAD software.. File organization strategies for CAD files in a metalworking shop..Creating CAD files for your lathe can be as fun as a game of Tetris! First, keep your designs simple. Use clear shapes and labels to avoid confusion. Next, always name your files wisely so you won’t be playing hide and seek later. A good template helps too, like having a secret cheat code!

Organizing your CAD files in a metalworking shop is like sorting out your sock drawer. Make a folder for each project and stick to a naming system. This way, you won’t mix up parts, especially those tiny screws that seem to vanish into thin air! Here’s a quick table to illustrate:

| Folder Name | Contents |

|---|---|

| Project_A | Designs, Specs, Notes |

| Project_B | Parts List, Drawings, CAD Files |

By keeping files neat and tidy, you’ll save time and avoid searching under your desk for that one elusive design file. Happy crafting!

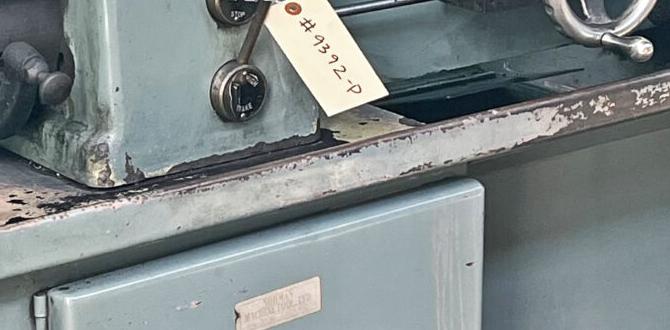

Metal Lathe Maintenance Essentials

Key components of metal lathe maintenance (e.g., lubrication, cleaning).. Importance of regular maintenance for longevity and performance..Taking care of your metal lathe is like keeping a pet—it needs love and attention! Regular lubrication keeps parts moving smoothly, while cleaning removes pesky chips and dirt. Think of it as giving your lathe a spa day! If you skip maintenance, you might find your lathe grumbling like a hungry bear. A little effort goes a long way, improving performance and extending its life. Remember, a well-maintained lathe is a happy lathe!

| Maintenance Task | Frequency |

|---|---|

| Lubrication | Weekly |

| Cleaning | After each use |

| Check belts and gears | Monthly |

| Inspect for wear | Quarterly |

Step-by-Step Metal Lathe Maintenance Procedures

Detailed maintenance checklist for daily, weekly, and monthly tasks.. Common troubleshooting tips and methods for metal lathe issues..Keeping your metal lathe in tip-top shape is crucial. Here’s a fun and simple maintenance checklist to follow. Daily tasks should include cleaning the lathe and checking for loose parts. Weekly, tighten anything that’s wobbly and oil key areas to avoid rust. Monthly, give it a good scrub and inspect the belts. If things go south, like weird noises or a rough cut, don’t panic! Check for dirt buildup or loose screws. Remember, a happy lathe makes a happy owner!

| Maintenance Tasks | Daily | Weekly | Monthly |

|---|---|---|---|

| Cleaning | ✔ | ✔ | |

| Check Loose Parts | ✔ | ||

| Tighten and Oil | ✔ | ||

| Inspect Belts | ✔ |

Utilizing CAD Files for Maintenance Procedures

How CAD files can aid in understanding lathe components during maintenance.. Creating maintenance schedules and visual aids using CAD software..CAD files are like treasure maps for lathe maintenance. They help you understand each component, making repairs easier and less scary. With clear visuals, you won’t need a magic wand to fix things! Create schedules and checklists to keep everything running smoothly. Think of CAD as your trusty sidekick, always ready to lend a hand.

| Benefits of CAD Files | Maintenance Tasks |

|---|---|

| Clear Visuals: Easy to see how parts fit together. | Check oil levels regularly. |

| Detailed Diagrams: Know where every bolt goes. | Inspect belts every month. |

So, explore CAD files for a smoother maintenance adventure. You’ll save time, avoid confusion, and maybe have a laugh or two while you’re at it!

Resources for Lathe CAD Files and Maintenance Tools

Recommended online platforms for downloading CAD files.. Essential maintenance tools for metal lathes and where to find them..Finding CAD files for lathes can be a breeze! Websites like GrabCAD and Thingiverse offer tons of files for free. You can download what you need with just a click. Don’t forget to check out user reviews to find the best files. For keeping those metal lathes in tip-top shape, you’ll want some essential tools. A good set of wrenches, oil, and a clean cloth are must-haves. You can find these tools in local hardware stores or online. Here’s a quick guide:

| Resource | Type |

|---|---|

| GrabCAD | CAD Files |

| Thingiverse | CAD Files |

| Home Depot | Tools |

| Amazon | Tools |

Keeping your lathe happy will help you make awesome projects. A cheerful lathe is like a cat—don’t ignore it, or it’ll stop purring!

Conclusion

In summary, using CAD files can make metal lathe maintenance easier. They help you visualize parts and repairs clearly. Regular maintenance keeps your lathe running smoothly and extends its life. Remember to check for wear and tear often. For more helpful tips, explore additional resources or guides about lathe care. Your machine will thank you!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Cad Files And Metal Lathe Maintenance:Sure! Here are five questions about lathe CAD files and metal lathe maintenance: 1. What is a lathe? A lathe is a machine that spins material to shape it. 2. What are CAD files? CAD stands for Computer-Aided Design. These files help us plan and design things on a computer. 3. How do we take care of a metal lathe? We should clean it often, check for wear, and oil the moving parts. 4. Why is it important to maintain a lathe? Maintaining a lathe makes it last longer and work better. 5. Can I find CAD files for my lathe online? Yes, many websites share free CAD files for different lathes.

Sure! Just let me know what question you want me to answer.

What Are The Key Components Of A Metal Lathe That Should Be Included In Cad Files For Maintenance Documentation?When we create CAD files for a metal lathe, we should include important parts. First, we need the bed, which is the base that holds everything together. Next, include the spindle, which spins the metal. We also need the carriage that moves tools to shape the metal. Don’t forget the tailstock, which helps support the metal while we work. These parts help us understand how to fix and care for the lathe.

How Can Cad Software Be Utilized To Design Custom Parts For The Repair And Maintenance Of A Metal Lathe?You can use CAD software to design special parts for a metal lathe. First, you draw the part on the computer. Then, you can change the size and shape easily. This helps you make parts that fit perfectly for repairs. Finally, you can print the design or send it to a machine to create the part.

What Are The Best Practices For Maintaining A Metal Lathe To Ensure Optimal Performance And Longevity?To keep your metal lathe in great shape, always clean it after each use. Check the oil levels regularly and add oil when needed. You should also tighten any loose parts to prevent problems. Make sure to replace worn-out tools and parts promptly. Finally, cover the lathe when you’re not using it to protect it from dust and dirt.

How Can Detailed Cad Files Assist In Troubleshooting Common Issues With Metal Lathes During Maintenance?Detailed CAD files, which are special computer drawings, can help us fix metal lathes better. They show us exactly how each part fits together. When we have a problem, we can use these drawings to find the issue quickly. This helps us understand what to check and what tools to use. With the right information, we can fix things faster and keep the lathe working well!

What Maintenance Schedules And Checklists Can Be Created Using Cad Files To Streamline Metal Lathe Upkeep?We can use CAD files to create easy maintenance schedules for metal lathes. First, we list tasks like cleaning and checking oil levels. Then, we make checklists to remind us what to do and when. We can even add pictures from the CAD files to show how to do each task. This way, taking care of the lathe becomes quicker and easier!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Cad Files And Metal Lathe Maintenance:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about lathe CAD files and metal lathe maintenance: 1. What is a lathe? A lathe is a machine that spins material to shape it. 2. What are CAD files? CAD stands for Computer-Aided Design. These files help us plan and design things on a computer. 3. How do we take care of a metal lathe? We should clean it often, check for wear, and oil the moving parts. 4. Why is it important to maintain a lathe? Maintaining a lathe makes it last longer and work better. 5. Can I find CAD files for my lathe online? Yes, many websites share free CAD files for different lathes.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know what question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Components Of A Metal Lathe That Should Be Included In Cad Files For Maintenance Documentation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we create CAD files for a metal lathe, we should include important parts. First, we need the bed, which is the base that holds everything together. Next, include the spindle, which spins the metal. We also need the carriage that moves tools to shape the metal. Don’t forget the tailstock, which helps support the metal while we work. These parts help us understand how to fix and care for the lathe.”}},{“@type”: “Question”,”name”: “How Can Cad Software Be Utilized To Design Custom Parts For The Repair And Maintenance Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use CAD software to design special parts for a metal lathe. First, you draw the part on the computer. Then, you can change the size and shape easily. This helps you make parts that fit perfectly for repairs. Finally, you can print the design or send it to a machine to create the part.”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Maintaining A Metal Lathe To Ensure Optimal Performance And Longevity?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your metal lathe in great shape, always clean it after each use. Check the oil levels regularly and add oil when needed. You should also tighten any loose parts to prevent problems. Make sure to replace worn-out tools and parts promptly. Finally, cover the lathe when you’re not using it to protect it from dust and dirt.”}},{“@type”: “Question”,”name”: “How Can Detailed Cad Files Assist In Troubleshooting Common Issues With Metal Lathes During Maintenance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Detailed CAD files, which are special computer drawings, can help us fix metal lathes better. They show us exactly how each part fits together. When we have a problem, we can use these drawings to find the issue quickly. This helps us understand what to check and what tools to use. With the right information, we can fix things faster and keep the lathe working well!”}},{“@type”: “Question”,”name”: “What Maintenance Schedules And Checklists Can Be Created Using Cad Files To Streamline Metal Lathe Upkeep?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use CAD files to create easy maintenance schedules for metal lathes. First, we list tasks like cleaning and checking oil levels. Then, we make checklists to remind us what to do and when. We can even add pictures from the CAD files to show how to do each task. This way, taking care of the lathe becomes quicker and easier!”}}]}