Have you ever wondered how machines like lathes work? A lathe is a fascinating tool that helps shape metal. It spins the metal while cutting tools carve out shapes. But how can you create your own lathe? That’s where lathe CAD files come into play.

These files are like blueprints for building a lathe. They tell you exactly what to do. Plus, they help you visualize the parts you need. Imagine having an amazing metal lathe motor that powers your projects! With the right designs, making your own lathe is possible.

Did you know that many people use CAD files to build their own tools? It can be a fun weekend project. You dream big, and your lathe can bring those dreams to life. Are you ready to explore how to use lathe CAD files for your metal lathe motor? Let’s dive in!

Lathe Cad Files: Essential For Metal Lathe Motor Projects

Understanding Lathe CAD Files for Metal Lathe Motors

Lathe CAD files are essential for designing parts to create metal lathe motors. These files allow users to visualize and plan their projects before starting. Did you know different motors can influence your lathe’s performance? Using the right motor makes your lathe more efficient, improving precision and speed. Plus, CAD software helps you make adjustments quickly. Imagine the creativity you can unleash with the right tools! Start exploring CAD files today for your metal lathe projects.Understanding Lathe CAD Files

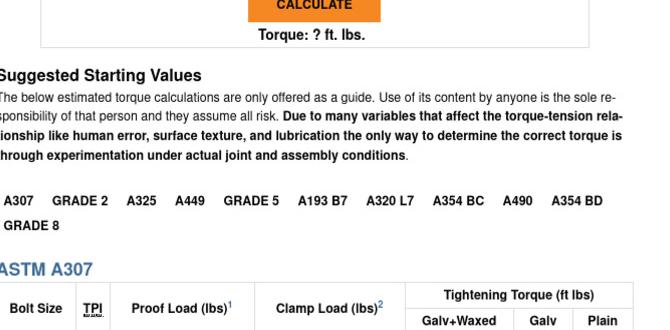

Definition and purpose of CAD files in lathe design. Importance of highquality CAD files for metal lathe functionality.CAD files are special digital drawings used in lathe design. They help create a precise plan for making metal lathes. High-quality CAD files are important because they ensure the lathe works properly. Good designs lead to better performance and fewer problems. Without quality files, you may face issues during production. That’s why careful design is key.

What are the benefits of CAD files in lathe design?

High-quality CAD files offer accurate measurements, which lead to better machining results. They also save time and reduce errors. This makes the manufacturing process smoother.

Key Advantages of CAD Files:

- Precise designs

- Time-saving features

- Reduced manufacturing errors

- Easy sharing and editing

How to Acquire Lathe CAD Files

Sources for downloading CAD files (industrial design websites, manufacturers). Best practices for searching and selecting appropriate files.Finding CAD files for a lathe is easy with the right sources. Check out industrial design websites or manufacturers’ online stores. These places often offer free or paid files you can download. Be sure to look for files that match your lathe model. Here are some useful tips:

- Use specific keywords, like “lathe CAD files”

- Check user reviews before downloading

- Look at the file format to ensure compatibility

This way, you’ll find the best files for your lathe CAD files metal lathe motor project.

Where can I find CAD files for lathe design?

You can find CAD files on industrial design websites and from manufacturers. Many offer downloadable resources.

Editing and Customizing CAD Files for Metal Lathes

Tools and software used for editing CAD files (AutoCAD, SolidWorks, Fusion 360). Tips for customizing designs to fit specific motor specifications.Editing CAD files for metal lathes can be fun and helpful. You can use great tools like AutoCAD, SolidWorks, and Fusion 360. These programs let you change designs to fit your needs.

- AutoCAD: Easy to use for drawing and editing.

- SolidWorks: Perfect for 3D models and simulations.

- Fusion 360: Great for collaboration and cloud access.

To customize your design, always check the motor’s specifications. Adjust dimensions correctly. This ensures your parts fit without any issues.

What are some tips for customizing CAD files?

Check motor size and power. Adjust the thickness and adjust dimensions for better fitting.Customizing CAD files lets you build exactly what you need. Make sure to experiment with these tools! They can help you become an expert in no time.

Integrating CAD Files with Lathe Motors

Steps for integrating CAD designs with lathe motor systems. Common challenges and troubleshooting tips.Getting CAD designs to work with lathe motors can feel like solving a tricky puzzle. First, upload your CAD files into the lathe software. Next, connect your motor to the system. Make sure the settings match your design. It’s vital to check motor strength—too weak, and you’ll get a sad whirr. Watch out for common hiccups! Loose wires can be as frustrating as a stubborn pickle jar. If things go haywire, double-check connections or restart the whole shebang.

| Common Challenges | Troubleshooting Tips |

|---|---|

| Incompatible file formats | Convert files to a compatible format |

| Motor not responding | Check all connections and power supply |

| Settings mismatch | Ensure settings align with the CAD design |

Case Studies of Successful CAD File Implementations

Examples of businesses that improved designs using CAD files. Lessons learned and outcomes from these implementations.Many businesses have used CAD files to improve their designs. For example, a toy company saved time and money by using CAD for new toys. They created better designs quickly. A furniture maker also used CAD files, which helped them create more stylish pieces. They gained better customer reviews because of this. These cases show the benefits of using CAD effectively. Key lessons include:

- Design improvements can happen faster.

- Better products increase customer satisfaction.

- Cost savings can be significant.

What are the benefits of using CAD files?

Using CAD files helps in creating designs quickly, improving accuracy, and reducing errors.

Future Trends in Lathe CAD Designs

Innovations in CAD technology affecting metal lathes. Predictions for future CAD file capabilities and motor integration.New ideas in CAD technology are making metal lathes cooler and easier to use. Imagine a lathe that talks to you! That’s not just a fun thought – thanks to smart motors and advanced CAD designs, it might be possible. Future CAD files could allow for better customization. You might even connect your metal lathe to your phone for control and updates. Who knew making stuff could be this high-tech? Buckle up, because the future of metal lathe design looks pretty bright!

| Innovation | Benefit |

|---|---|

| Smart motors | Enhanced control |

| Mobile connectivity | Remote management |

| Advanced customization | Tailored designs |

Resources for Further Learning

Recommended online courses and tutorials for CAD file creation and manipulation. Community forums and groups for sharing expertise and resources.Learning more about CAD file creation can be fun and easy! Check out some awesome online courses and tutorials. Websites like Udemy and Coursera offer great options to get you started. Also, don’t miss out on community forums. They are perfect for sharing tips and asking questions. You’ll make friends and learn a lot. Plus, who doesn’t love a good group chat about metal lathes? Remember, sharing is caring!

| Resource | Description |

|---|---|

| Udemy | Courses on CAD and 3D design. |

| Coursera | University-level courses on engineering and design. |

| Forums to discuss CAD projects. | |

| Facebook Groups | Community support for CAD enthusiasts. |

Conclusion

In conclusion, metal lathe motor CAD files are essential for designing and building lathes. They help you understand the parts and mechanics involved. By using these files, you can create more efficient machines. We encourage you to explore these files further and try designing your own lathe project. With practice, you’ll learn valuable skills and bring your ideas to life!FAQs

What Types Of Cad Files Are Most Commonly Used For Designing Metal Lathe Components And Accessories?When designing parts for a metal lathe, we often use CAD files like STEP and IGES. STEP stands for Standard for the Exchange of Product model data. IGES means Initial Graphics Exchange Specification. These file types help share designs easily with others. They let you see and change the shapes of parts on a computer.

How Can I Modify Existing Cad Files To Fit A Specific Motor For A Metal Lathe Design?You can change CAD (Computer-Aided Design) files by using special software. First, open the file in the software. Then, measure your motor. Next, make the parts in the design match your motor’s size. Finally, save the file so you can use it later.

What Software Tools Are Recommended For Creating And Optimizing Cad Files For Metal Lathe Motors?To create and improve CAD files for metal lathe motors, you can use software like AutoCAD and SolidWorks. These programs help you draw and design your parts. They also allow you to make changes easily. Another good option is Fusion 360, which is great for beginners. All these tools make it easier for you to create cool designs!

Are There Any Online Repositories Or Libraries Where I Can Find Free Cad Files For Metal Lathe Motors?Yes, you can find free CAD files for metal lathe motors online. Websites like Thingiverse and GrabCAD have many designs you can download. You just need to search for “metal lathe motors” on those sites. Remember to check the rules for each file. Happy building!

What Considerations Should Be Taken Into Account When Selecting A Motor For A Metal Lathe In Relation To Its Cad Design?When you choose a motor for a metal lathe, think about how strong it needs to be. It should match the size of your lathe and the type of work you do. Check if the motor fits the design you made in CAD (Computer-Aided Design). Make sure it can turn at the right speed for your projects. Finally, consider how the motor will connect to the lathe without any trouble.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Types Of Cad Files Are Most Commonly Used For Designing Metal Lathe Components And Accessories? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When designing parts for a metal lathe, we often use CAD files like STEP and IGES. STEP stands for Standard for the Exchange of Product model data. IGES means Initial Graphics Exchange Specification. These file types help share designs easily with others. They let you see and change the shapes of parts on a computer.”}},{“@type”: “Question”,”name”: “How Can I Modify Existing Cad Files To Fit A Specific Motor For A Metal Lathe Design? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can change CAD (Computer-Aided Design) files by using special software. First, open the file in the software. Then, measure your motor. Next, make the parts in the design match your motor’s size. Finally, save the file so you can use it later.”}},{“@type”: “Question”,”name”: “What Software Tools Are Recommended For Creating And Optimizing Cad Files For Metal Lathe Motors? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To create and improve CAD files for metal lathe motors, you can use software like AutoCAD and SolidWorks. These programs help you draw and design your parts. They also allow you to make changes easily. Another good option is Fusion 360, which is great for beginners. All these tools make it easier for you to create cool designs!”}},{“@type”: “Question”,”name”: “Are There Any Online Repositories Or Libraries Where I Can Find Free Cad Files For Metal Lathe Motors? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, you can find free CAD files for metal lathe motors online. Websites like Thingiverse and GrabCAD have many designs you can download. You just need to search for metal lathe motors on those sites. Remember to check the rules for each file. Happy building!”}},{“@type”: “Question”,”name”: “What Considerations Should Be Taken Into Account When Selecting A Motor For A Metal Lathe In Relation To Its Cad Design? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you choose a motor for a metal lathe, think about how strong it needs to be. It should match the size of your lathe and the type of work you do. Check if the motor fits the design you made in CAD (Computer-Aided Design). Make sure it can turn at the right speed for your projects. Finally, consider how the motor will connect to the lathe without any trouble.”}}]}