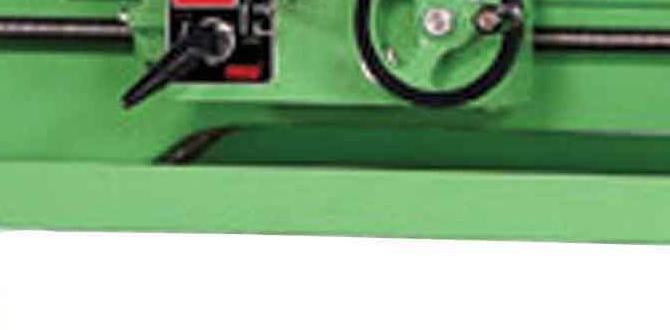

Imagine standing in a workshop, surrounded by machines that hum softly as they work. One of those machines is a lathe, a tool that shapes metal with precision. Do you know how it all comes together?

In this article, we’ll explore lathe CAD files and how they help with metal lathe operations. CAD, or computer-aided design, makes planning and creating parts easier. It transforms ideas into detailed blueprints. Wouldn’t it be amazing to turn a simple sketch into a real metal component?

Picture this: a metal rod spinning, while the sharp tool slices away tiny bits. This is the magic of a lathe in action! The right CAD files make these operations smoother and more accurate. Knowing this can greatly enhance your skills or spark a new hobby.

Let’s dive into the fascinating world of lathe CAD files. You’ll soon see how they change the way metal is shaped and crafted. Ready to uncover the secrets?

Lathe Cad Files: Essential For Metal Lathe Operations

Understanding Lathe CAD Files and Metal Lathe Operations

Lathe CAD files are essential for anyone working with metal lathes. They help create precise designs for parts and tools. Imagine constructing something intricate, like a toy car or a jewelry piece. How cool would that be? These files guide users step-by-step through the metal lathe operations, ensuring accuracy. Skills in reading lathe CAD files can unlock creativity in projects. They can make your crafting journey smoother and more efficient, leading to amazing results!Understanding Lathe CAD Files

Definition and significance of CAD files in lathe operations. Common formats and software used for creating lathe CAD files.CAD files are like treasure maps for metal lathe operations. They guide the lathe in turning materials into amazing shapes. These files are significant because they ensure precision, making sure no one ends up with a wobbly table leg! Common formats include .dwg and .dxf. Popular software that creates these files is AutoCAD and SolidWorks. Just think of software as the magic wand that turns ideas into real things!

| Format | Software |

|---|---|

| .dwg | AutoCAD |

| .dxf | SolidWorks |

Creating Effective Lathe CAD Files

Stepbystep guide to designing lathe CAD files. Best practices for accuracy and precision in CAD designs.Designing great lathe CAD files requires a few simple steps. First, sketch your idea on paper. It helps to visualize before going digital. Next, choose your CAD software wisely. Some programs are user-friendly and perfect for beginners. Remember to keep measurements straight—it’s like measuring twice and cutting once! For the best results, always check your work for accuracy and precision. Even the tiniest mistake can lead to a big mess. So, double-check before you hit ‘print’.

| Best Practices | Description |

|---|---|

| Keep it Simple | Start with basic shapes to avoid confusion. |

| Use Layers | Organize your design for easier editing. |

| Save Often | Don’t lose work; save your progress frequently. |

Integrating CAD Files with CNC Lathes

Explanation of CNC lathes and their benefits. How to upload and utilize CAD files in CNC lathe operations.CNC lathes are like magical spinning tops for metal! They shape materials with precision, making them great for creating everything from toys to car parts. One big benefit is their speed; they can crank out projects in a snap. Uploading CAD files to a CNC lathe is a piece of cake! You simply send the design from your computer to the lathe, and voila! The machine does the hard work while you sit back, sip your soda, and feel like a wizard.

| Steps to Upload CAD Files | Benefits |

|---|---|

| 1. Create your design in CAD. | Save time and effort. |

| 2. Connect your computer to the lathe. | Ensure high precision. |

| 3. Hit ‘send’ and watch the magic happen! | Make complex shapes easily. |

With CAD files, your ideas come to life, and you get to be the mastermind behind it all! Pretty neat, huh?

Common Metal Lathe Operations Explained

Detailed descriptions of turning, facing, and boring operations. Tips for selecting the right operation for your project.Metal lathe operations are like three superheroes in the machining world: turning, facing, and boring. Turning shapes the outside of a material, making it round and pretty. It’s like giving a block of ice a makeover. Facing is all about the flat finish. Imagine cutting the top off a cake to make it look neat! Lastly, boring is the technique for drilling deeper holes, perfect for creating passages or connecting parts. Picking the right operation can save time and effort, so choose wisely!

| Operation | Purpose | Best For |

|---|---|---|

| Turning | Shaping the outside | Curved designs |

| Facing | Smoothing the surface | Flat finishes |

| Boring | Creating holes | Custom fit parts |

Safety Precautions in Metal Lathe Operations

Key safety measures to follow when using a metal lathe. Importance of proper personal protective equipment (PPE).Using a metal lathe is exciting, but safety comes first! Always wear proper personal protective equipment (PPE). This includes safety glasses to protect your eyes and gloves to keep your hands safe. Remember, loose clothing is a big no-no! It can get caught in the machine, and we definitely don’t want that. Let’s keep our fingers intact!

Here are some key safety measures:

| Safety Measure | Why It’s Important |

|---|---|

| Wear safety goggles | To protect your eyes from flying debris |

| Use gloves | To prevent cuts and scrapes |

| No loose clothing | To avoid getting caught in the lathe |

Remember, safety isn’t boring; it’s clever! As my grandmother used to say, “Better safe than sorry, and always look before you lathe!”

Troubleshooting Common Issues in Lathe Operations

Identifying and resolving common problems encountered during operations. Maintenance tips to prevent operational issues.Lathe machines can have problems during use. Recognizing these issues can save time. Common problems include chatter, vibration, and tool wear. Check the tool and workpiece tightness to prevent these. Regular maintenance is key. Keep the lathe clean and lubricated. This helps avoid issues and keeps operations smooth.

What are some common issues with lathe operations?

Some common issues include:

- Chatter

- Excessive vibration

- Tool wear

How can you maintain a lathe for better operation?

Regular maintenance tips include:

- Keep the lathe clean

- Lubricate moving parts

- Check alignment regularly

Future Trends in Lathe Technology and CAD Integration

Emerging technologies in metal lathe operations. Predictions for the evolution of CAD file usage in manufacturing.Imagine a world where metal lathes operate like smart robots with minds of their own! New technologies are popping up every day, improving metal lathe operations. Soon, machines will read CAD files like bedtime stories, making production faster and easier. Experts predict that CAD integration will help cut errors and save time. We might even see machines high-fiving each other for a job well done! How cool is that?

| Emerging Technology | Description |

|---|---|

| AI Integration | Machines that learn and adapt for better performance. |

| 3D Printing | Creating parts directly from CAD files without extra steps. |

| IoT Connectivity | Connecting machines to the internet for real-time updates. |

Conclusion

In summary, lathe CAD files simplify metal lathe operations. They help you design precise parts easily. Understanding these files is essential for anyone working with lathes. You can practice using CAD software to improve your skills. Explore different designs and create your projects. Keep learning about lathes, and you’ll become more confident in your abilities. Happy machining!FAQs

What Are The Key Considerations When Creating Cad Files For Metal Lathe Operations?When making CAD files for a metal lathe, you should think about a few important things. First, make sure your design is the right size for the lathe. Second, check that the shapes can be cut easily with the tools. It’s also good to see if the parts fit together well before you start making them. Finally, save your files in a format that the lathe can understand.

How Can Cad Software Improve Precision And Efficiency In Designing Components For Metal Lathes?CAD software, which stands for Computer-Aided Design, helps you create really accurate designs for metal lathes. With CAD, you can easily make changes and see how they look right away. This saves time and helps avoid mistakes. You can also measure parts precisely, making them fit together better. Overall, CAD makes designing faster and more exact!

What Types Of Cad File Formats Are Commonly Used For Programming Cnc Metal Lathes?For programming CNC metal lathes, we often use CAD file formats like DXF and DWG. DXF stands for Drawing Exchange Format, and it helps share drawings. DWG is also a format that contains design data. We can also use G-code files, which tell the CNC machine how to move. These formats help us turn our designs into real metal parts.

What Features Should Be Included In A Cad File To Facilitate Various Lathe Operations, Such As Turning, Facing, And Threading?To help with lathe operations, a CAD file should have clear measurements and shapes. You should include the material type so you know how hard it is. Adding details for each step, like where to cut, is also important. Make sure to show which parts will be turned, faced, or threaded. This will make it easier for you to use the lathe correctly.

How Do Different Metal Lathe Operations Impact The Design Of Cad Files And The Subsequent Machining Process?Different metal lathe operations change how we create designs in Computer-Aided Design (CAD) files. If we plan to cut, shape, or thread metal, we need to make sure our designs fit those operations. For example, some shapes can’t be made if the lathe can’t reach them. This means we have to think carefully about our designs before we start machining. By planning well, we can make sure our final product looks and works great!