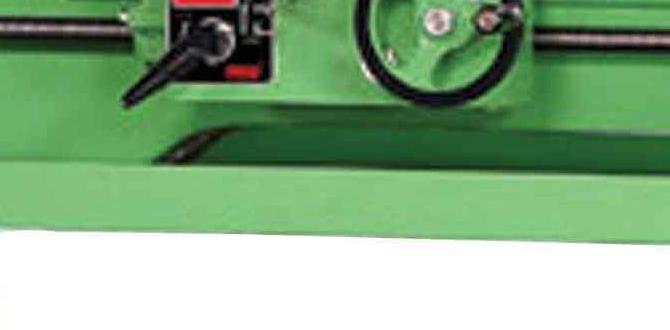

Have you ever watched a metal lathe in action? It’s fascinating how it can shape metal with precision. But did you know that you can use lathe CAD files to help design parts for your projects? These files can make your work easier and more fun.

Imagine crafting a custom quill for your metal lathe. With the right CAD files, you can bring your ideas to life. Many hobbyists and experts use these files to save time and achieve amazing results. Isn’t that exciting?

This article will explore how lathe CAD files can transform your metal working experience. We’ll learn about the quill, a vital part of many lathes, and how to find the best files. Whether you’re a beginner or an expert, there’s something here for you.

Get ready to dive into the world of metal lathes and discover the magic of CAD files!

Lathe Cad Files: Essential Metal Lathe Quill Designs

Discovering Lathe CAD Files for Metal Lathe Quills

Lathe CAD files help you design parts for metal lathes. Understanding the quill is essential for accuracy. Did you know a quill allows control over tool depth? With proper CAD files, you can tailor designs to fit your lathe perfectly. This ensures smoother operations and better outcomes. Explore the benefits of using these files. They save time and improve precision, making metalworking easier and more enjoyable.Understanding Lathe CAD Files

Definition and purpose of CAD files in metalworking. Importance of precision in lathe design for quills.CAD files, or Computer-Aided Design files, are like blueprints for metalworking. They create detailed drawings of parts, helping makers envision their final products. These files ensure that each piece is shaped perfectly. Precision in lathe design is crucial, especially for quills, as even a tiny error can lead to big problems. Imagine trying to fit a square peg in a round hole—awkward, right? So, a precise design is key to smooth operations!

| Aspect | Importance |

|---|---|

| Precision | Ensures parts fit and work well together |

| Efficiency | Reduces waste and saves time |

| Quality | Creates reliable and durable products |

Types of CAD Files for Metal Lathes

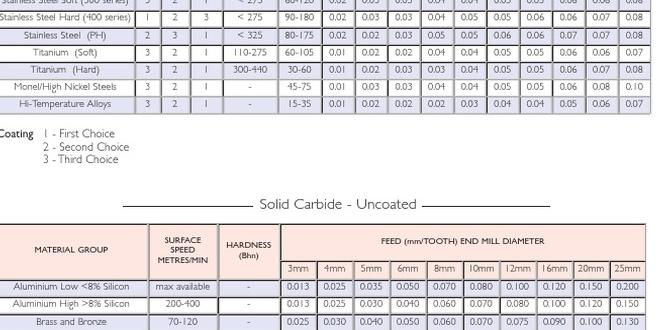

Common formats (DWG, STL, DXF, etc.). Benefits of using each file type for metal lathe quill design.Different kinds of CAD files work well for designing metal lathe quills. Here are common formats:

- DWG: This format keeps layers and colors. It’s great for detailed designs.

- STL: Used for 3D printing. It shows objects clearly in three dimensions.

- DXF: Ideal for sharing between different programs. It helps in easy collaboration.

Using the right format can help save time and improve accuracy. Choosing wisely makes the design process smoother.

What are the main benefits of each CAD file type?

DWG allows for detailed plans. STL is perfect for 3D printing. DXF means easier teamwork.

Designing a Metal Lathe Quill: Key Considerations

Essential dimensions and tolerances for quill design. Materials selection for durability and performance.Designing a metal lathe quill is like baking a cake; you need the right mix of ingredients. First, consider the dimensions and tolerances. Too tight, and it might not fit; too loose, and it could wobble like a bad dancer! Next, choose materials carefully for durability and performance. Steel is popular because it’s strong, while aluminum is lighter but might not last as long. Let’s look at a simple table to compare:

| Material | Durability | Weight |

|---|---|---|

| Steel | High | Heavy |

| Aluminum | Medium | Light |

Choosing the right materials and dimensions will help create a perfect quill ready for action. So, think twice before picking your metal buddy!

Where to Find Quality Lathe CAD Files

Popular online repositories and communities (e.g., GrabCAD, Thingiverse). How to evaluate the quality and accuracy of downloaded files.Searching for quality lathe CAD files? Popular websites like GrabCAD and Thingiverse offer many options. These platforms have large communities sharing designs. Always check the ratings and comments; they reveal how others feel about the files. Look at the file details, too. If someone mentions it worked well for them, it’s likely a good choice. You can also ask for help if you’re unsure!

Where can I find lathe CAD files?

You can explore GrabCAD and Thingiverse for a range of lathe CAD files. Both sites have active users and support communities.

How to check quality?

- Read user reviews.

- Check star ratings.

- Review specific file details.

Customizing Existing CAD Files for Your Needs

Tools and software recommendations for editing CAD files. Tips for modifying designs to fit specific metal lathe models.Editing CAD files can feel tricky, but using the right tools make it easy. Popular software includes Tinkercad, Fusion 360, and FreeCAD. These programs allow you to customize designs to fit your metal lathe. Here are some quick tips:

- Always check your lathe model’s specs.

- Make small changes to avoid errors.

- Test the updated design on a sample material.

Simple adjustments can lead to great results!

What software can I use to edit CAD files?

Use software like Tinkercad, Fusion 360, or FreeCAD to easily modify CAD files for your needs.

Integrating CAD Files into Your Workflow

Software compatibility and usage in CNC machining. Common troubleshooting tips when importing CAD files into CNC machines.Using CAD files in your CNC work can really speed things up—kind of like a cheetah on roller skates! But first, ensure your software plays nice with the CNC machine. Compatibility is key; otherwise, you might end up with a digital puzzle piece that just won’t fit. When things go awry, check your file format and settings. They can be a bit picky, like a cat with a new toy!

Here are some common fixes for importing hiccups:

| Issue | Solution |

|---|---|

| File won’t open | Check software compatibility! |

| Sketch looks weird | Zoom in and fix the scale! |

| Machine malfunction | Restart and try again! |

With a little patience, your CAD files will fit like a sock in a shoe. Happy machining!

Case Studies: Successful Projects Using Lathe CAD Files

Examples of innovative designs and projects completed with CAD files. Lessons learned from realworld applications in metalworking.Using CAD files in metalworking can lead to some amazing outcomes! For instance, projects like custom bicycle frames showed just how creative builders can be. Builders used lathe CAD files for precise cuts. This ensured that everything fit perfectly, making the bikes not only cool but also safe to ride. If you think bicycles are fun, wait till you see a metal sculpture created using the same techniques!

| Project | Outcome |

|---|---|

| Custom Bicycle Frame | Unique design and perfect fit |

| Metal Sculpture | Eye-catching artwork with smooth finishes |

Lessons from these projects show the importance of planning. Precise designs save time and materials. So, the next time you think metalworking is boring, remember the innovative paths these CAD files can open up!

Future Trends in CAD and Metal Lathe Design

Emerging technologies in CAD software and metalworking. Predictions for the evolution of lathe quill design and fabrication.New technologies are changing how we use CAD software and design metal lathes. These advancements make designs faster and more accurate. For lathe quills, we can expect lighter materials and smarter features. Many believe these changes will save time and reduce waste, making work better for everyone.

- 3D printing will allow quick prototyping.

- Artificial Intelligence will help create smart designs.

- New materials will enhance durability and performance.

What is the future of metal lathe design?

The future of metal lathe design looks bright! Innovations will lead to more efficient machines. Users will benefit from faster operations and less energy use. This means a brighter, greener manufacturing future!

Conclusion

In summary, lathe CAD files for metal lathe quills are essential for creating precise parts. They help you design and visualize your projects better. You can find many resources online to learn more about using these files. Understanding how to work with CAD files can improve your skills. So, dig deeper and start your next project with confidence!FAQs

What Are The Key Design Features To Consider When Creating Cad Files For A Metal Lathe Quill?When you design CAD files for a metal lathe quill, focus on some key features. First, make sure to get the right measurements for everything. You want parts to fit together nicely. Next, think about the materials you’ll use. Some materials are stronger than others. Lastly, check that your design allows for easy movement and adjustment. This helps the quill work better!

How Can I Find Or Create Compatible Cad Files For A Custom Metal Lathe Quill?You can find CAD files online by searching for your metal lathe model. Websites like Thingiverse or GrabCAD have many free designs. If you want to create your own files, you can use programs like Tinkercad or Fusion 360. Start by drawing your quill’s shape and size. Then, save your design in a CAD file format to use with your lathe.

What Software Programs Are Best Suited For Designing Metal Lathe Quill Components In Cad?Some great software programs for designing metal lathe quill parts in CAD (Computer-Aided Design) are Fusion 360, SolidWorks, and AutoCAD. These programs let you create 3D models easily. They have tools that help you shape and measure your designs. You can also see how your parts will look and fit together before making them. Using these programs makes designing fun and precise!

Are There Any Standard Dimensions Or Specifications For Metal Lathe Quills That Should Be Included In Cad Files?Yes, there are common sizes for metal lathe quills. You should include the length, diameter, and hole sizes in your CAD files. Also, note the materials used and any special features. This helps everyone understand how to use the quill correctly. Make sure your drawings are clear and easy to read!

How Can I Ensure The Accuracy And Precision Of My Cad Designs For A Metal Lathe Quill Before Manufacturing?To make sure your CAD designs are correct, double-check all your measurements. Look at the parts from different angles to spot mistakes. Use tools like a ruler or caliper to compare your design with real-life sizes. Ask a friend to review your design too, as a fresh pair of eyes can help. Finally, make a simple model to see if everything fits together properly before making it for real.