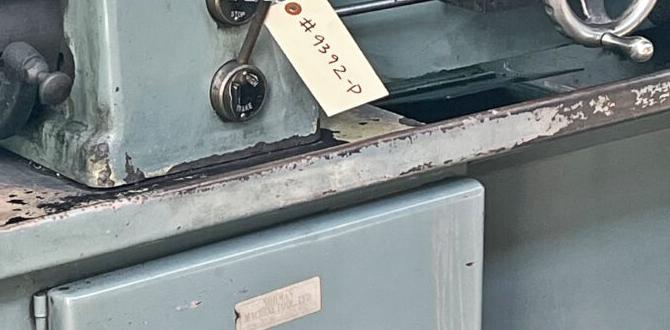

Have you ever watched a lathe in action? It spins metal and shapes it into amazing parts, like magic. One key component of a lathe is the tailstock. The tailstock helps hold the workpiece steady while it spins. This simple piece is vital for precision tasks.

But how do you get the perfect tailstock for your metal lathe? That’s where lathe CAD files come in. These files let you design and create a custom tailstock. You can make it fit your specific needs. Imagine being able to tweak the design just for your project! Isn’t that exciting?

In this article, we will dive into the world of lathe CAD files and discover how they can help you with your metal lathe tailstock. You’ll learn tips to get started and create your very own designs. So, let’s explore this fascinating topic together!

Lathe Cad Files: Essential For Metal Lathe Tailstock Design

Understanding Lathe CAD Files for Metal Lathe Tailstock

Lathe CAD files for metal lathe tailstocks help designers create precise parts. These files streamline manufacturing by allowing easy adjustments. Have you ever wondered how engineers design complex machinery? They use CAD files to visualize and refine their work. Tailstocks play a vital role in stabilizing workpieces during machining. This crucial support enhances accuracy and prevents errors. With the right CAD resources, metal lathe projects become simpler and more efficient. Discover the power of these digital tools today!Understanding Lathe CAD Files

Definition and purpose of CAD files in metalworking. Types of CAD formats commonly used.CAD files, or Computer-Aided Design files, are like blueprints for metalworkers. They help create detailed designs for tools and parts, like lathe tailstocks. Think of them as the treasure maps of the machining world! There are different types of CAD formats, each with its quirky characteristics. Here’s a handy table for you:

| CAD Format | Usefulness |

|---|---|

| .DWG | Great for detailed drawings. |

| .DXF | Perfect for sharing designs. |

| .STL | Excellent for 3D printing. |

Using these formats, metalworkers can easily share their projects and bring ideas to life. Remember, a good design makes for smoother machining, and who doesn’t want that?

The Importance of Tailstocks in Metal Lathes

Functionality and significance of tailstocks. Comparison of fixed vs. movable tailstocks.A tailstock is an important part of a metal lathe. It holds the other end of the workpiece tightly. This helps keep everything stable during cutting. Fixed tailstocks do not move. They are great for simple jobs. However, movable tailstocks can slide. This is useful for different lengths and types of metal parts. Tailstocks prevent wobbles. They make sure your work is accurate and smooth.

Why Are Tailstocks Important?

Tailstocks are key for support, accuracy, and stability when working with metal.Benefits of Tailstocks:

- Hold workpieces securely

- Allow for different lengths

- Improve cutting precision

Finding Quality Lathe CAD Files

Recommended resources for downloading CAD files. Criteria for evaluating the quality of CAD files.Searching for good CAD files can feel like finding a needle in a haystack. But don’t worry, there are plenty of places where you can snag quality files! Websites like GrabCAD and Thingiverse are fantastic resources. They boast a treasure trove of designs for metal lathe tailstocks. Remember to check reviews and user ratings, as they can reveal the file’s quality. Look for files that have clear instructions and good feedback. Nobody wants to puzzle over a confusing plan!

| Resource | Pros |

|---|---|

| GrabCAD | Wide selection, community support |

| Thingiverse | User-friendly, diverse designs |

Evaluating CAD files doesn’t have to be rocket science. Just keep your eye out for high-quality graphics and detailed descriptions. These signals can mean you’ve struck gold! Happy downloading!

How to Create Your Own Tailstock CAD Files

Stepbystep guide for designing tailstock CAD files. Tips for using CAD software effectively.Creating your own tailstock CAD files is exciting! Here’s how to do it step by step:

- Choose a CAD software you like. Popular choices are AutoCAD or Fusion 360.

- Start with a new file and sketch the base of the tailstock.

- Add the features, like slots and holes, that make it functional.

- Check the dimensions carefully to ensure everything fits together.

- Save your design frequently to avoid losing your work.

For best results, keep these tips in mind:

- Use layers to keep your design organized.

- Use the “undo” button whenever you make a mistake.

- Explore tutorials to learn new tools.

With practice, designing CAD files will become easier!

How can I start using CAD software effectively?

You can start using CAD software effectively by exploring built-in tutorials and practicing regularly. A good understanding of tools will help you create better designs. Remember, small steps lead to big progress!

Modifying Existing CAD Files for Tailstocks

Best practices for editing CAD files. Common modifications and their implications.Editing CAD files for tailstocks can enhance your metal lathe’s performance. Follow these best practices for smooth modifications:

- Always back up the original CAD files.

- Use clear naming conventions for new files.

- Change dimensions carefully to avoid issues.

- Test modifications on a smaller scale first.

Common edits include adjusting dimensions, adding features, or changing materials. Each change can affect the lathe’s precision and strength, so always double-check your work.

What are common edits for tailstocks in CAD files?

Common modifications include resizing components, altering connecting parts, and adding features. These changes can improve your lathe’s functionality, but ensure to test each modification properly to avoid problems.

Integrating Tailstock CAD Files into CNC Machining

Process of converting CAD files for CNC machines. Key considerations for compatibility.Using CAD files for CNC machines involves a few important steps. First, you must convert the CAD files into a format the CNC machine can read. This usually means using software to translate the designs. Key things to check include:

- File types supported by your CNC machine.

- The accuracy of the design conversion.

- Settings for tools and speeds required for cutting.

Integrating these files correctly will help ensure your metal lathe tailstock works perfectly. Proper preparation leads to better results!

What is the importance of CAD files in CNC machining?

CAD files help create precise designs for machines. They improve accuracy and save time during production. These files guide your CNC machine to make exact cuts, enhancing efficiency. This is essential for creating detailed parts, like a metal lathe tailstock.

Case Studies: Successful Tailstock Implementations

Examples of projects that benefited from specific tailstock designs. Lessons learned from tailstock modifications.Many projects have thrived thanks to smart tailstock designs. For example, a small workshop improved accuracy by adjusting their tailstock. This simple change helped them make better parts. They learned that the right design can save time and reduce waste. Here are some key takeaways:

- Adjusting tailstock can enhance stability.

- Customization meets specific project needs.

- Small changes lead to big improvements.

What can we learn from tailstock modifications?

Tailstock modifications teach us important lessons. They help enhance precision and efficiency. Simple tweaks can impact project success greatly.

Future Trends in Lathe CAD File Development

Innovations in CAD technology affecting lathe design. Predictions for the future of metal lathe tailstocks and CAD files.In the world of lathe design, innovation is spinning fast! New CAD technology is shaking things up. Designers can now create more detailed models with ease. This means better metal lathe tailstocks that can make precision cuts like a hot knife through butter. Future predictions suggest even smarter tailstocks that might come with sensors! 🚀 Imagine a tailstock that knows when you need a coffee break. That would be top-notch tech!

| Innovation | Impact |

|---|---|

| Smart Sensors | Enhances accuracy and reduces errors. |

| Mobile CAD Access | Allows for design changes on-the-go. |

| 3D Printing Integration | Enables rapid prototyping of parts. |

Innovative trends promise to sprinkle even more excitement into the world of lathe CAD files. This is not your grandfather’s metal lathe anymore!

Conclusion

In conclusion, lathe CAD files help you design precise components for metal lathes, including the tailstock. Understanding these files lets you create better projects. We encourage you to explore CAD software and try making your own designs. With practice, you’ll gain valuable skills and confidence. Keep learning and experimenting, and you’ll build amazing projects!FAQs

Here Are Five Related Questions On The Topic Of Lathe Cad Files For Metal Lathe Tailstocks:Sure! CAD stands for Computer-Aided Design. Lathe CAD files help us create detailed designs for parts of a metal lathe, like the tailstock. The tailstock holds tools and helps with cutting metal. These files can guide you in building or fixing a lathe. You can find CAD files online or create your own using special computer programs.

Sure! Please tell me the question you would like me to answer.

What Software Is Commonly Used To Create Cad Files For Designing Metal Lathe Tailstocks?To create CAD files for designing metal lathe tailstocks, you can use programs like AutoCAD, SolidWorks, or Fusion 360. These programs help you draw and plan your designs on a computer. You can see how your tailstock will look before making it in metal. Each of these software tools is user-friendly and great for beginners.

Are There Any Open-Source Cad File Resources Specifically For Metal Lathe Tailstock Designs?Yes, there are open-source CAD (Computer-Aided Design) files for metal lathe tailstocks. You can find these files on websites like Thingiverse and GrabCAD. These sites let you download designs for free. You can also modify them to fit your needs. It’s a great way to learn and create!

How Can I Modify Existing Cad Files For A Metal Lathe Tailstock To Fit My Specific Lathe Model?To change CAD files for your metal lathe tailstock, you need a CAD program. First, open the file in the program. Then, measure your lathe to see what size you need. Use the tools in the program to change the shape and size. Finally, save the new design and check to make sure it fits!

What Are The Key Dimensions And Features To Consider When Designing A Cad File For A Metal Lathe Tailstock?When designing a CAD file for a metal lathe tailstock, think about the size and shape first. You need to know how big the tailstock should be to fit your lathe. Then, consider the holes for screws to hold it in place. Don’t forget about the parts that help it move smoothly. Lastly, make sure everything is strong enough to handle heavy work.

Where Can I Find Tutorials Or Guides For Modeling Metal Lathe Tailstocks In Cad Software?You can find tutorials on YouTube. Just search for “metal lathe tailstock CAD tutorial.” Websites like Instructables also have guides. You can check forums where people talk about CAD designs. Don’t forget to ask your teacher or librarian for help, too!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Cad Files For Metal Lathe Tailstocks:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! CAD stands for Computer-Aided Design. Lathe CAD files help us create detailed designs for parts of a metal lathe, like the tailstock. The tailstock holds tools and helps with cutting metal. These files can guide you in building or fixing a lathe. You can find CAD files online or create your own using special computer programs.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please tell me the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Software Is Commonly Used To Create Cad Files For Designing Metal Lathe Tailstocks?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To create CAD files for designing metal lathe tailstocks, you can use programs like AutoCAD, SolidWorks, or Fusion 360. These programs help you draw and plan your designs on a computer. You can see how your tailstock will look before making it in metal. Each of these software tools is user-friendly and great for beginners.”}},{“@type”: “Question”,”name”: “Are There Any Open-Source Cad File Resources Specifically For Metal Lathe Tailstock Designs?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are open-source CAD (Computer-Aided Design) files for metal lathe tailstocks. You can find these files on websites like Thingiverse and GrabCAD. These sites let you download designs for free. You can also modify them to fit your needs. It’s a great way to learn and create!”}},{“@type”: “Question”,”name”: “How Can I Modify Existing Cad Files For A Metal Lathe Tailstock To Fit My Specific Lathe Model?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To change CAD files for your metal lathe tailstock, you need a CAD program. First, open the file in the program. Then, measure your lathe to see what size you need. Use the tools in the program to change the shape and size. Finally, save the new design and check to make sure it fits!”}},{“@type”: “Question”,”name”: “What Are The Key Dimensions And Features To Consider When Designing A Cad File For A Metal Lathe Tailstock?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When designing a CAD file for a metal lathe tailstock, think about the size and shape first. You need to know how big the tailstock should be to fit your lathe. Then, consider the holes for screws to hold it in place. Don’t forget about the parts that help it move smoothly. Lastly, make sure everything is strong enough to handle heavy work.”}},{“@type”: “Question”,”name”: “Where Can I Find Tutorials Or Guides For Modeling Metal Lathe Tailstocks In Cad Software?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can find tutorials on YouTube. Just search for metal lathe tailstock CAD tutorial. Websites like Instructables also have guides. You can check forums where people talk about CAD designs. Don’t forget to ask your teacher or librarian for help, too!”}}]}