Have you ever wondered how metal parts are made so perfectly? One secret lies in lathe calibration. If you’ve seen a metal lathe in action, you know it can create amazing shapes. But did you know that the gear train inside that lathe is crucial for its accuracy? Without proper calibration, even the best gear train can lead to mistakes.

Imagine trying to build a model car. If the wheels don’t fit right, the car won’t roll smoothly. This is similar to how a metal lathe works. Each part must work together perfectly. Calibration helps ensure the lathe operates as it should, making it a vital step.

Here’s a fun fact: a well-calibrated lathe can produce parts that are only a few thousandths of an inch off! That’s like trying to split a hair! In this article, we will explore how to calibrate a lathe and why it’s important. Let’s dive into the world of metal lathes and their gear trains!

Lathe Calibration: Ensuring Precision In Metal Lathe Gear Train

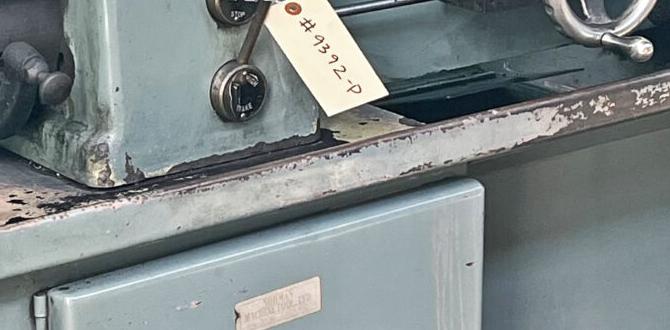

Lathe Calibration: Understanding the Metal Lathe Gear Train

Calibration keeps your metal lathe precise. It ensures accuracy in your workpieces. Did you know that a small miscalibration can affect the entire project? The gear train plays a crucial role here. It helps control speed and feed rate, impacting how smooth your cuts are. Adjusting the lathe’s gears correctly can save you time and resources. Imagine finishing a project with perfect dimensions every time! Proper calibration is the key to success in metalworking.Understanding Lathe Calibration

Definition of lathe calibration and its importance.. Key factors influencing calibration accuracy in metal lathes..Calibration for a lathe is a method to ensure it works correctly. This process is crucial. It helps make precise cuts and shapes in metal. Accurate calibration boosts quality and reduces errors. Without it, projects can go wrong.

Key factors for calibration accuracy in metal lathes include:

- Proper tool alignment

- Maintenance of the gear train

- Environmental conditions

Each of these aspects plays a significant role. A small mistake can lead to big issues. Regular checks help keep everything on track!

Why is lathe calibration important?

Calibration is vital for safe and accurate machining. It reduces waste and improves productivity. This care increases tool life, ensuring you get the most from your lathe.

The Role of Gear Trains in Metal Lathes

Explanation of gear trains and their functionality.. Impact of gear train configuration on lathe performance..Gear trains help metal lathes run smoothly by transferring power. They use a series of gears to control speed and torque. This setup allows the lathe to operate at different speeds based on the task. A good gear train design can significantly improve lathe performance.

- They control how fast the lathe turns.

- They adjust the cutting power for different materials.

- Different configurations affect precision and smoothness.

Choosing the right gear train can make your lathe work better. With the correct setup, you get stronger cuts and a smoother finish.

How do gear trains affect lathe performance?

They improve speed, precision, and cutting power. The right configuration increases efficiency and enhances the quality of the finished product.

Tools and Equipment Needed for Calibration

Essential tools for accurate calibration of metal lathes.. Recommended brands and models for precision calibration tools..To calibrate a metal lathe accurately, you need the right tools. Here are the essentials:

- Tape Measure: For measuring lengths.

- Dial Indicator: It helps check the precision of the lathe.

- Level: Ensures your lathe is flat and stable.

- Caliper: Measures the diameter of materials.

- Wrench Set: Tightens parts securely.

For quality calibration tools, consider brands like Starrett and Mitutoyo. They offer reliable models for precise work. Remember, the right tools make metal lathe calibration much easier!

What tools do I need for lathe calibration?

The essential tools are tape measure, dial indicator, and caliper. They ensure your lathe runs accurately.

Step-by-Step Calibration Process

Detailed procedure for calibrating a metal lathe gear train.. Common mistakes to avoid during the calibration process..Calibrating your metal lathe gear train is like tuning a delicate instrument. Start by checking the gear alignment—small mistakes can lead to big problems. Next, make sure the backlash is just right; too much, and your cuts will be wobbly. Regular checks mean smoother operation. Watch out for common errors like forgetting to tighten parts back up. A loose gear is like a dance partner who steps on your toes!

| Common Mistakes | Solutions |

|---|---|

| Misaligning gears | Double-check every connection. |

| Ignoring lubrication | Use proper lubricants to keep it smooth. |

| Forgetting adjustments | Keep a checklist handy! |

Following these steps carefully makes calibration easier. Remember, a well-calibrated lathe means better projects. And who wouldn’t want to make their next creation shine like a freshly polished apple?

Maintaining Calibration Over Time

Strategies for regular maintenance to ensure continued accuracy.. Signs that indicate recalibration is necessary..Regular maintenance is key for your lathe to work well. Checking your equipment often helps keep it accurate. Here are some good strategies:

- Clean the lathe often to remove dirt.

- Inspect parts for wear and tear regularly.

- Use proper lubrication to prevent rust.

Watch for signs that tell you recalibration is needed:

- Inconsistent measurements.

- Strange noises during operation.

- Visible wear on gears or parts.

Taking these steps can extend the life of your lathe and ensure it works accurately.

How often should you recalibrate your lathe?

Recalibrating your lathe should happen at least once a year or sooner if you notice issues.

Common Issues and Troubleshooting Tips

Frequent calibration problems faced by metal lathe operators.. Effective troubleshooting techniques to resolve calibration issues..Calibration issues with metal lathes can feel like battling a dragon with a toothpick! Operators often face problems like incorrect measurements or gears not aligning properly. These hiccups can lead to frustrating results. But fear not! Here’s a handy guide to troubleshoot your way to success:

| Problem | Solution |

|---|---|

| Inaccurate Settings | Check and adjust the calibration settings. |

| Slipping Gears | Inspect and tighten all gear connections. |

| Unusual Noises | Lubricate gears and bearings as needed. |

Always remember, a smooth lathe makes for happy machining! If all else fails, consult your manual or a friendly expert. Happy turning!

Case Studies: Successful Calibration Practices

Realworld examples of businesses benefiting from proper calibration.. Lessons learned from case studies and their implications for best practices..Many businesses have found success by properly calibrating their machines. For instance, a small factory improved its output by 30% after fixing its metal lathe gear train. Imagine doubling your candy bar production! They learned that regular checks keep machines happy and working well. This means fewer mistakes and less wasted time. Proper calibration isn’t just smart; it can be funny how a little adjustment makes a big difference! It’s like tuning a guitar—small changes lead to beautiful music.

| Business | Improvement Achieved |

|---|---|

| Factory A | 30% increase in output |

| Workshop B | 20% less waste |

| Shop C | 15% more efficiency |

Conclusion

In conclusion, calibrating a metal lathe gear train is essential for precise machining. Proper calibration improves accuracy and extends tool life. Remember to regularly check your settings and make adjustments as needed. To learn more, you can read guides or watch videos on lathe maintenance. Start applying these tips today for better results in your projects!FAQs

Certainly! Here Are Five Questions Related To Lathe Calibration, Specifically Focusing On Metal Lathe Gear Trains:Sure! Here are five questions about metal lathe gear trains: 1. What is a gear train? A gear train is a set of gears that help turn the lathe. They help control how fast things spin. 2. Why do we calibrate a lathe? We calibrate a lathe to make sure it cuts accurately. This means our pieces will be the right size. 3. How often should we check the gears? You should check the gears regularly, like every month. This keeps them from wearing out and helps with accuracy. 4. What tools do we need for calibration? You will need simple tools like a ruler, a wrench, and a screwdriver. These help us adjust and fix the gears. 5. Can you fix the gear train yourself? Yes! With some practice, you can fix it yourself. Just follow the steps carefully and ask for help if you need it.

Sure! Please provide the question you’d like me to answer.

What Is The Importance Of Calibrating The Gear Train In A Metal Lathe For Achieving Accurate Machining Results?Calibrating the gear train in a metal lathe helps it work correctly. When we do this, it makes sure the machine moves at the right speed. This means the metal piece we are shaping will be just the right size and shape. If we don’t calibrate, our work might not be perfect. So, calibrating helps us make better, more accurate things!

How Do You Determine The Correct Gear Ratios For A Specific Machining Operation On A Metal Lathe?To find the right gear ratios for a metal lathe, you start by checking the speed needed for your job. You can look at the tool and material you’re using. Next, you see which gears can help you reach that speed. Then, you adjust the gears on the lathe until they match the speed you want. Finally, make sure everything is tight and ready to use!

What Are Common Symptoms Of An Improperly Calibrated Gear Train In A Metal Lathe, And How Can They Affect The Final Product?If a gear train in a metal lathe isn’t set up right, you might notice some problems. The lathe could make uneven cuts, or it might skip parts of the job. This can lead to pieces that aren’t the right size or shape. You might end up with a product that looks messy or doesn’t fit together well. Proper calibration helps us make things that are smooth and clean!

What Steps Should Be Taken To Troubleshoot And Recalibrate The Gear Train Of A Metal Lathe If Inconsistencies In Diameter Or Finish Are Observed?To fix problems with your metal lathe, first check the gears for dirt or wear. Clean them if needed and make sure they fit well. Next, check the settings on the lathe to ensure they are correct. If things still don’t look right, adjust the gears carefully and test the lathe again. Keep repeating until you get a smooth finish!

How Can Regular Maintenance And Calibration Of The Gear Train In A Metal Lathe Improve Overall Machine Performance And Lifespan?Regular maintenance and calibration of the gear train in a metal lathe help keep the machine running smoothly. When we take care of the gears, they work better and last longer. This means your projects will have better quality and you won’t need to fix things as often. Keeping everything in good shape also saves money in the long run. So, taking care of your lathe is really important!