Have you ever tried to turn a handwheel and it just wouldn’t budge? It’s frustrating, right? The lathe carriage handwheel is a crucial part of many machines. When it breaks or becomes hard to turn, it can slow down your work. But don’t worry! Repairing it can be easier than you think.

Many people might not know that a simple fix can save both time and money. Imagine if you could get your lathe running smoothly again with just a few tools! It’s like bringing an old friend back to life. With some basic steps, you can fix that stubborn handwheel.

In this article, we will explore how to repair a lathe carriage handwheel step by step. You’ll learn what tools you need and how to use them safely. Plus, we’ll share tips that make the repair process quick and fun! Let’s dive in and give your lathe a new lease on life!

Essential Guide To Lathe Carriage Handwheel Repair Techniques

Understanding Lathe Carriage Handwheel Repair

Maintaining your lathe is key to smooth operation. Repairing a lathe carriage handwheel can seem tough, yet it’s achievable. First, check for wear or damage. A seasoned operator often finds lubrication helps. Did you know that a simple clean can dramatically improve performance? By fixing the handwheel, you enhance control and precision. Imagine turning a rough job into a smooth finish! Plus, a functioning handwheel extends your lathe’s life. Don’t let a small issue halt your work!Understanding the Lathe Carriage Handwheel

Function and purpose of the handwheel in lathe operations. Common types of handwheels used in lathes.The handwheel on a lathe is like the steering wheel of a car—crucial for maneuvering! It controls the movement of the carriage, allowing you to make precise cuts. Imagine trying to slice bread without knowing how to move the knife! There are different handwheel types, such as the manual handwheel and the power feed handwheel, each serving a special role in lathe operations, making the process smoother and more fun. You can think of it as the difference between pushing a shopping cart and having a robot do it for you!

| Handwheel Type | Function |

|---|---|

| Manual Handwheel | Used for manual positioning and adjustments. |

| Power Feed Handwheel | Automates movement for smoother operations. |

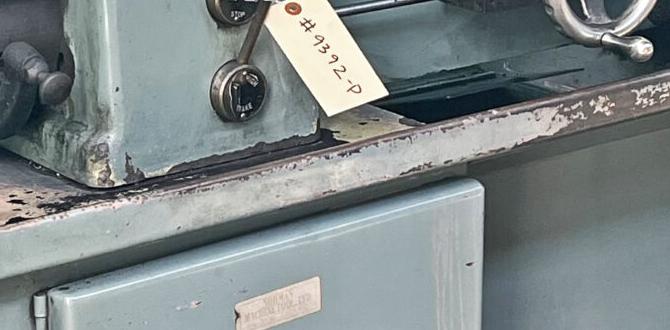

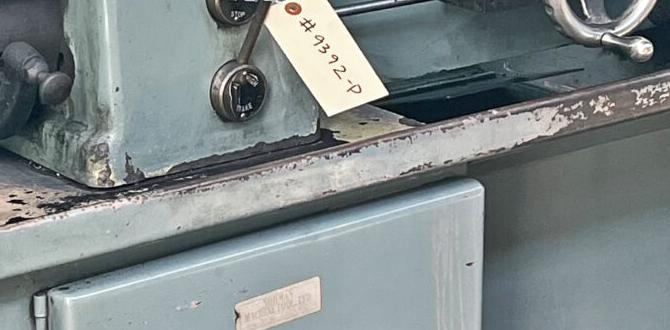

Identifying Issues with the Handwheel

Common problems faced with the handwheel. Signs that indicate the need for repair or replacement.Handwheel troubles can be sneaky! Sometimes, it feels like a workout just to turn it. Common issues include tightness or strange squeaks. Signs that it’s time for a fix might be difficulty in moving the lathe or a wobbly handwheel. It could also look less shiny and more like a rusty superhero! If you notice these signs, check it before it decides to put up a fight. Let’s take a look at some handy signs in the table below:

| Issue | Signs |

|---|---|

| Tight movement | Hard to turn the handwheel |

| Squeaking noise | Annoying sounds when turning |

| Wobbling | Handwheel shakes during use |

| Rust buildup | Rough and dull appearance |

Tools and Materials Needed for Repair

List of essential tools for handwheel repair. Recommended materials and replacement parts.For fixing that handwheel, grab a few key tools and materials. First, you’ll need a sturdy wrench, screwdrivers, and pliers. These friends will help you take apart and put back your lathe carriage. Don’t forget some replacement parts like bearings or a new handwheel. You want everything to spin smoothly, not squeak like a rusty hinge! Here’s a neat table that lists your essentials:

| Tool/Material | Purpose |

|---|---|

| Wrench | Loosen and tighten nuts |

| Screwdrivers | Remove screws |

| Pliers | Grip and pull |

| Bearings | Replace worn parts |

| New Handwheel | Upgrade functionality |

With these tools, you’re all set to tackle the repair. It’s like building a LEGO masterpiece, but with fewer colorful blocks and more grease!

Step-by-Step Repair Process

Prerepair preparations and safety measures. Detailed breakdown of the repair process. Tips for ensuring accuracy and effectiveness.Before diving into the world of lathe carriage handwheel repair, you need to take a few important steps. First, *safety* is key! Wear goggles to protect your eyes—those little metal shavings can feel like tiny ninjas. Next, gather your tools: a wrench, screwdriver, and maybe a snack for energy (repairing can be tough work!).

| Tool | Purpose |

|---|---|

| Wrench | Tightening or loosening bolts |

| Screwdriver | Removing screws safely |

| Goggles | Protecting your eyes |

| Snack | Fuel for repair energy |

Now, let’s break down the repair process. Start by disconnecting the power, then inspect the handwheel carefully. If you spot damage, **replace** the worn parts. Use a ruler to ensure everything lines up correctly—nobody likes a wobbly wheel! Remember, precise measurements lead to a smoother operation. Regular checks can also help avoid future headaches.

Lastly, keep some creativity in your toolbox! If your handwheel looks extra shiny after cleaning, give it a funny name; every machine deserves a personality! Happy repairing!

Maintenance Tips for Longevity

Best practices for maintaining the handwheel. Frequency of maintenance checks and adjustments.Keeping your handwheel in great shape is simple. First, always check it for dirt or rust. Clean it with a soft cloth. Lubricate moving parts regularly to keep them working smoothly. Look for signs of wear or damage. Aim to do these checks every month. Keeping a routine helps your lathe last longer. Don’t wait for problems to appear. Prevention is key!

How often should you check your handwheel?

It’s best to check your handwheel and its parts every month. This protects it from damage. It ensures a long life for your lathe.

Best practices for maintenance:

- Clean regularly.

- Lubricate moving parts.

- Inspect for wear or damage.

When to Seek Professional Help

Situations that warrant professional intervention. How to choose a reliable service technician.Sometimes, fixing a lathe carriage handwheel can feel like a puzzle with missing pieces. If you experience strange noises or see parts falling off, it’s time to call for help. Trust those moments—they’re signs that something’s wrong. Choosing a service technician can be like picking a pizza toppings. Make sure to check reviews and ask for recommendations. The right person will get your lathe spinning smoothly again, leaving you free to focus on creating awesome projects, not stressing over repairs.

| Signs You Need Help | Tips for Choosing a Technician |

|---|---|

| Strange noises | Check reviews |

| Visible damage | Ask for recommendations |

| Frequent breakdowns | Look for experience |

Frequently Asked Questions (FAQs)

Common queries regarding lathe carriage handwheel repair. Detailed answers to each question to clarify doubts.Many people have questions about lathe carriage handwheel repair. Here are some common queries and clear answers:

What tools do I need for repairs?

You will need basic tools like wrenches, screwdrivers, and lubricant. Always check the manual for specific tools for your lathe.

How often should I check the handwheel?

It’s best to check the handwheel regularly, ideally every month. Regular checks can help spot issues early.

Can I repair it myself?

Yes, many repairs can be done by yourself. However, seek help if the problem seems complex.

What signs indicate a problem?

- Difficulty turning the handwheel.

- Noisy operation.

- Loose parts or visible wear.

Repairing the handwheel keeps your lathe running well. Understanding these questions helps make repairs easier and safer.

Conclusion

In conclusion, repairing a lathe carriage handwheel can improve your machine’s performance. You should inspect it regularly for wear and damage. Learning how to fix it yourself can save time and money. Remember to use the right tools and follow guides carefully. For more detailed instructions, check out repair videos or your lathe’s manual. Happy machining!FAQs

What Are The Common Signs That Indicate A Lathe Carriage Handwheel Needs Repair Or Replacement?You might notice a few signs if the lathe carriage handwheel needs fixing. First, it may get stuck or feel really hard to turn. You could also see cracks or damage on the wheel. If it wobbles too much while you turn it, that’s another sign. Lastly, if the machine makes strange noises, it’s time to check the handwheel.

How Can One Safely Disassemble The Lathe Carriage To Access The Handwheel For Repair?To safely take apart the lathe carriage, first, turn off the machine and unplug it. Next, find and remove any screws or bolts holding the carriage in place. You might need a screwdriver or wrench for this. Carefully lift the carriage off, and be gentle so you don’t break anything. Now, you can reach the handwheel to fix it!

What Tools And Materials Are Typically Needed For Repairing A Lathe Carriage Handwheel?To fix a lathe carriage handwheel, you need a few tools and materials. First, grab a screwdriver to take off parts. You might need a wrench to loosen bolts. A new bearing or grease can help it turn better. Don’t forget safety goggles to protect your eyes while you work!

What Techniques Can Be Used To Fix A Worn Or Damaged Handwheel On A Lathe Carriage?To fix a worn or damaged handwheel on a lathe carriage, you can try a few things. First, check if the handwheel is loose; if it is, tighten the screws. If it’s worn down, you might sand it lightly to make it smooth again. Another option is to replace the handwheel if it’s too damaged. Finally, adding some grease can help it turn easier.

Are There Any Preventive Maintenance Tips To Extend The Lifespan Of A Lathe Carriage Handwheel?To make your lathe carriage handwheel last longer, keep it clean. Use a soft cloth to wipe off dirt. Apply machine oil to keep it moving smoothly. Check for any loose parts and tighten them. Always store it in a dry place to prevent rust.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Common Signs That Indicate A Lathe Carriage Handwheel Needs Repair Or Replacement? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You might notice a few signs if the lathe carriage handwheel needs fixing. First, it may get stuck or feel really hard to turn. You could also see cracks or damage on the wheel. If it wobbles too much while you turn it, that’s another sign. Lastly, if the machine makes strange noises, it’s time to check the handwheel.”}},{“@type”: “Question”,”name”: “How Can One Safely Disassemble The Lathe Carriage To Access The Handwheel For Repair? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To safely take apart the lathe carriage, first, turn off the machine and unplug it. Next, find and remove any screws or bolts holding the carriage in place. You might need a screwdriver or wrench for this. Carefully lift the carriage off, and be gentle so you don’t break anything. Now, you can reach the handwheel to fix it!”}},{“@type”: “Question”,”name”: “What Tools And Materials Are Typically Needed For Repairing A Lathe Carriage Handwheel? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix a lathe carriage handwheel, you need a few tools and materials. First, grab a screwdriver to take off parts. You might need a wrench to loosen bolts. A new bearing or grease can help it turn better. Don’t forget safety goggles to protect your eyes while you work!”}},{“@type”: “Question”,”name”: “What Techniques Can Be Used To Fix A Worn Or Damaged Handwheel On A Lathe Carriage? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix a worn or damaged handwheel on a lathe carriage, you can try a few things. First, check if the handwheel is loose; if it is, tighten the screws. If it’s worn down, you might sand it lightly to make it smooth again. Another option is to replace the handwheel if it’s too damaged. Finally, adding some grease can help it turn easier.”}},{“@type”: “Question”,”name”: “Are There Any Preventive Maintenance Tips To Extend The Lifespan Of A Lathe Carriage Handwheel? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make your lathe carriage handwheel last longer, keep it clean. Use a soft cloth to wipe off dirt. Apply machine oil to keep it moving smoothly. Check for any loose parts and tighten them. Always store it in a dry place to prevent rust.”}}]}